Industrial Network Products

Motor control via network communication can detect the status of the motor directly by data. This results in a shorter development period and increased reliability and maintainability of the equipment. By expanding the network compatible product lineup, Oriental Motor meets diversifying network environments of factory automation.

Network-compatible products offer the following benefit:

- Simple wiring achieves space saving for wiring and smaller equipment size.

- Transmission distance can be extended making wiring route design easier and enables products to be positioned in appropriate locations.

- Simple wiring achieves a reduction in man-hours for the wiring process and in the cost of wiring.

- Operating status is monitored by product input/output information, alarm, etc. This achieves improved maintainability via the system.

- Simple wiring makes wiring and checking process easier when replacing the product.

Learn more about our αSTEP family of products with Network compatible drivers.

EtherNet/IP™ Compatible Drivers

AZ Series Stored Data drivers now offer EtherNet/IP™ communications for a battery-free, absolute mechanical sensor motor and driver solution.

For use with all Oriental Motor AZ Series motors and linear & rotary actuators equipped with the AZ Series.

- Built-in Protective Functions

- Monitoring Functions

- Support Software for Parameter Setting (free download)

- 24/48 VDC, Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with AZ Series Motors & Products

![]()

EtherNet/IP™ is a trademark of ODVA

EtherCAT Compatible Drivers

AZ Series Stored Data drivers now offer EtherCAT communications for a battery-free, absolute mechanical sensor motor and driver solution.

For use with all Oriental Motor AZ Series motors and linear & rotary actuators equipped with the AZ Series.

- Single-Axis and Multi-Axis Drivers

- Built-in Protective Functions

- Monitoring Functions

- Support Software for Parameter Setting (free download)

- 24/48 VDC, Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with AZ Series Motors & Products

![]()

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

PROFINET Compatible Drivers

The AZ Series motors can be controlled easily by using the PROFINET communications protocol.

The PROFINET compatible drivers comply with Conformance Class B.

Using the diagnostic tool of the host controller, network diagnostics and topology detection can be performed.

For use with all Oriental Motor AZ Series motors and linear & rotary actuators equipped with the AZ Series.

- Built-in Protective Functions

- Monitoring Functions

- Support Software for Parameter Setting (free download)

- 24/48 VDC, Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with AZ Series Motors & Products

PROFINET is a registered trademark of PROFIBUS Nutzerorganisation e.V. (PNO).

Modbus (RTU)

![]() Modbus is the open field network with Modbus Protocol installed. Modbus is used widely in field of factory and process automation because its protocol specification is open to the public and it is very simple.

Modbus is the open field network with Modbus Protocol installed. Modbus is used widely in field of factory and process automation because its protocol specification is open to the public and it is very simple.

- RS-485 Communication

- Wide Range of Products

- Can be used with Network Gateways for Industrial FA Network Communication

- Limited ROS support available

![]()

Modbus is a registered trademark of Schneider Automation Inc.

Controllers / Network Gateways

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to Oriental Motor's network compatible products is completed with one RS-485 communication cable.

- Compatible Networks:

CC-Link, MECHATROLINK-II, MECHATROLINK-III, EtherCat

*For use with Stored Data (Network) type

Compatible Networks

EtherNet/IP

With the EtherNet/IP driver, the operating data can sent from the host system or can be set in the driver and selected and executed from a host system. Host system connection and control are performed with I/O Stored Data or EtherNet/IP communications.

EtherNet/IP™ is a trademark of ODVA

EtherCAT

EtherCAT is an Ethernet (IEEE802.3)-compliant, open, high-speed industrial network system.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

PROFINET

With the PROFINET driver, the operating data can sent from the host system or can be set in the driver and selected and executed from a host system. Host system connection and control are performed with I/O Stored Data or PROFINET communications.

PROFINET is a registered trademark of PROFIBUS Nutzerorganisation e.V. (PNO).

Modbus (RTU)

Modbus is the open field network with Modbus Protocol installed. Modbus is used widely in field of factory and process automation because its protocol specification is open to the public and it is very simple.

Modbus is a registered trademark of Schneider Automation Inc.

CC-Link

CC-Link (Control&Communication Link) is the open field network promoted by CC-Link Partner Association.

CC-Link is a registered trademark of CC-LINK Partner Association.

MECHATROLINK

MECHATOLINK-II and MECHATROLINK-III are motion networks promoted by MECHATROLINK Members Association.

MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

SSCNETIII/H

SSCNETIII/H is an open field network promoted by Mitsubishi Electric Corporation.

SSCNETIII/H is a registered trademark of Mitsubishi Electric Corporation..

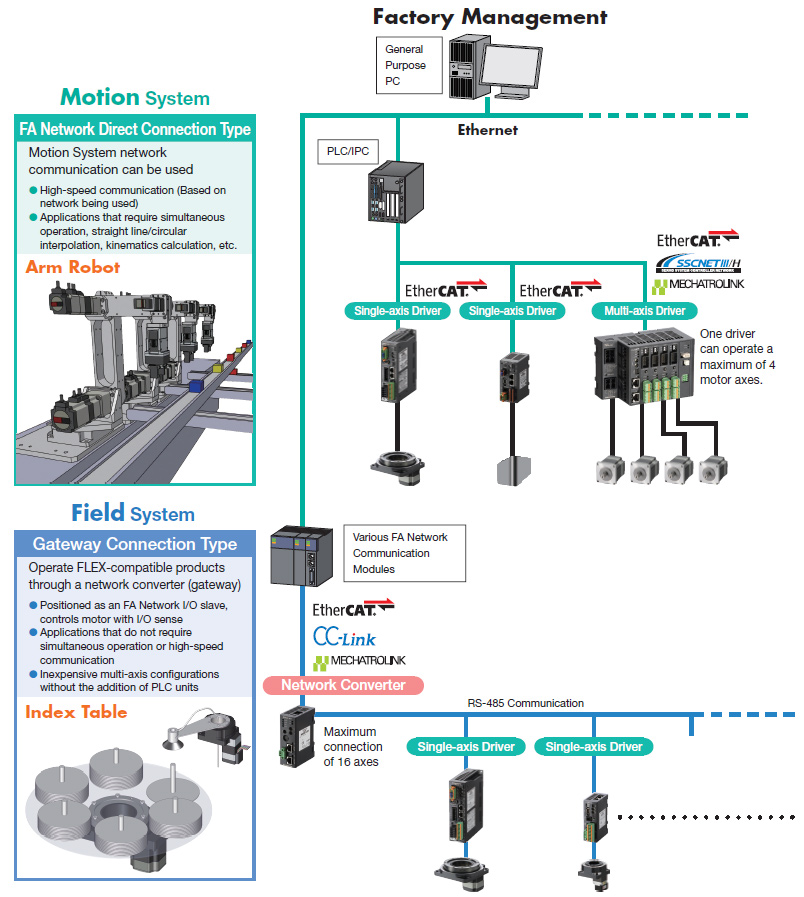

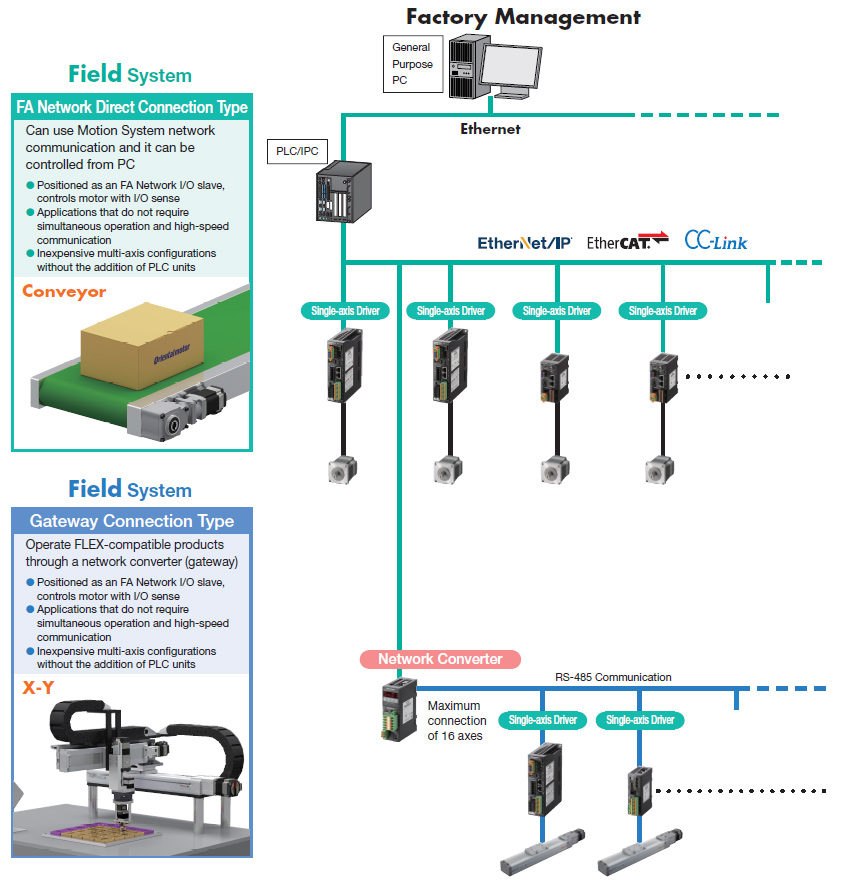

Usage Examples

Application cases for the FA Network Direct Connection Type and the Gateway Connection Type will be introduced below.

- Setting of operating data from the network and overwriting of data at any time

- Implementation of the monitoring necessary for analysis