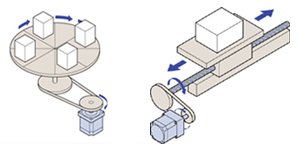

Position Control

Speed Control

Constant Speed

Temperature Control

Industrial Robots

Networking

We offer motion control solutions to meet the needs of key industries. Our motors ensure reliable performance for medical devices and surgical equipment. In semiconductor manufacturing, our products deliver high accuracy in cleanroom environments for wafer processing and assembly. For food packaging, our motors and actuators optimize automation for tasks like labeling.

Select the product that best suits your specific application to achieve optimal results.

Medical |

Semiconductor |

Food Packaging |

|

|

We provide more than 50,000 types of products around the world with quick delivery anytime, anywhere, centered on small industrial precision motors. We also have a highly specialized support system.

| High quality and high variety | Full support system | Quick Delivery | Expand globally |

Product Selection Guide

Choose from operation conditions and application types to find the appropriate product for your machine's needs. Compare products based on your specific requirements.

Motor Sizing Forms

Designed to make sizing a motor for your application faster and easier, these new sizing forms calculate the necessary torque, speed, stopping accuracy, and the system inertia that is also important to consider when selecting a proper motor for the application.

Service & Support

Products and technology are only valuable when coupled with skilled people and services to support them. Our Technical Support Team is available 15 hours a day, via phone, e-mail or live chat and offer advanced industry knowledge to help size and recommend the ideal motion products.

- 800 Technical Support

- Engineering & Application Engineering

- Motor Sizing & Selection

Events

Come Visit Oriental Motor and see the Latest Products and Technology:

- May 27 ~ 28, 2026 - Robotic Summit - Boston, MA

- June 22 ~ 25, 2026 - Automate - Chicago, IL

- Sep 14 ~ 19, 2026 - IMTS - Chicago, IL

- Oct 14 ~ 15, 2026 - Semicon - San Francisco, CA

- Oct 18 ~ 21, 2026 - Pack Expo International - Chicago, IL

- Oct 20 ~ 21, 2026 - RoboBusiness - Santa Clara, CA

News

Get the Latest Information and Announcements from Oriental Motor:

- 01-27-2026 - Oriental Motor Expands EC Fan Lineup with New EMR Series 180 mm and 200 mm Axial Fans

- 01-07-2026 - Oriental Motor Introduces First Stainless Steel BLDC Motor Compatible with BLE2 Series Drivers

- 12-12-2025 - Oriental Motor Expands MRS Series With New 300 mm AC Axial Fan

- 11-26-2025 - Oriental Motor Expands PKP Series with New 0.51” (13 mm) Stepper Motor Lineup

- 11-14-2025 - Oriental Motor Expands Lineup with BMU and BLE2 Series Drivers

- 11-03-2025 - Oriental Motor Expands Lineup with New IP65 Rated Rotary Encoders