Incremental Rotary Encoders

Rotary Encoders

The Rotary Encoder is small, thin, and lightweight magnetic incremental encoder that can be installed in tight spaces.

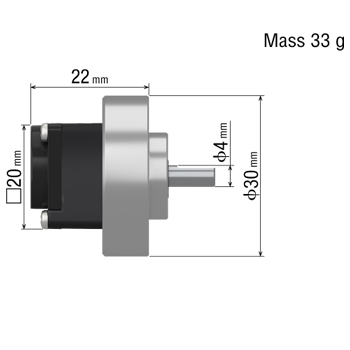

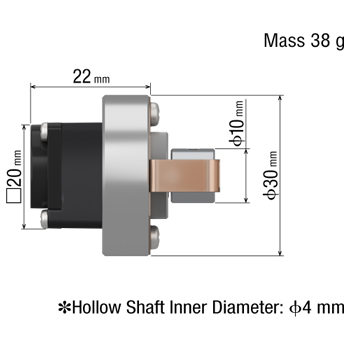

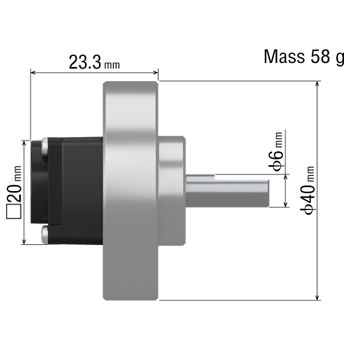

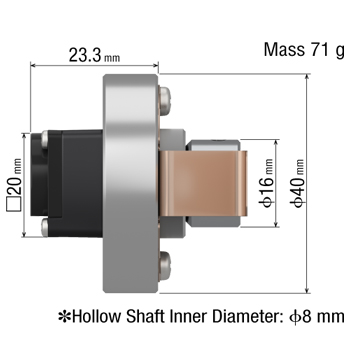

- Outer diameter ϕ30 mm and ϕ40 mm

- Incremental type

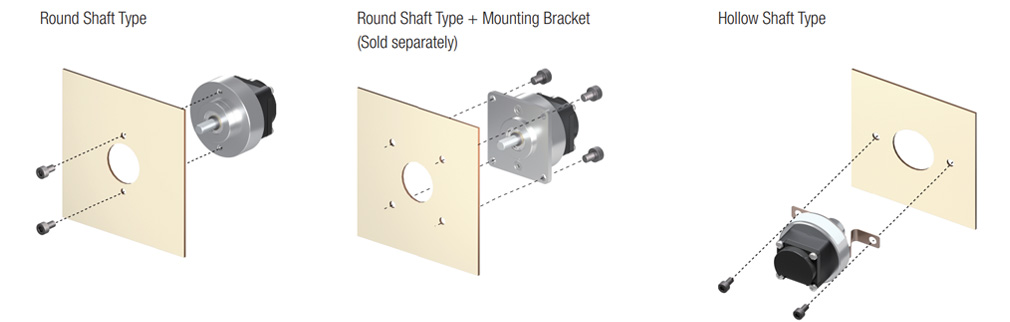

- Hollow shaft or round shaft type

- 100~4000 P/R

- Voltage, line driver, or open collector output

- IP20 or IP65 types

Product Features

Small, Thin, and Lightweight Magnetic Incremental Encoder

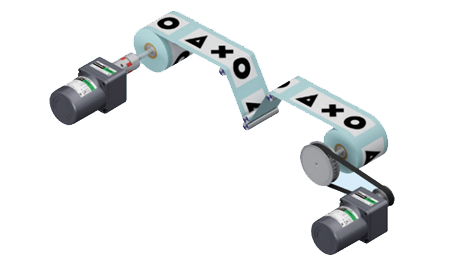

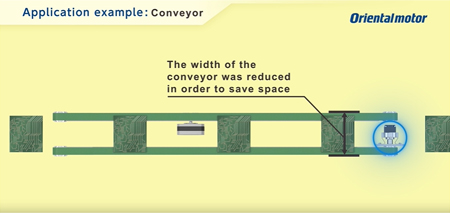

Since these rotary encoders are small, thin, and lightweight, they can be installed in tight spaces. Encoder resolutions vary from 100 to 4000 P/R. These rotary encoders are available in round shaft type or hollow shaft type with voltage, line driver, or open collector output. It can detect the actual position, speed, and direction of rotation of conveyors, belts, pulleys, and other mechanisms, contributing to the construction of predictive maintenance systems.

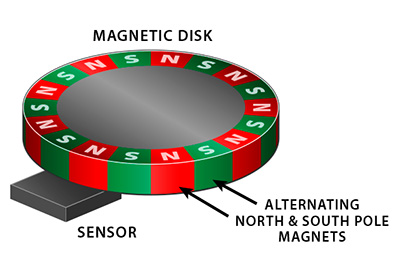

Magnetic encoders do not use a light emitter or a light receiver but still use a code wheel and a sensor. Instead of slits, the code wheel has alternating north and south pole magnets on the outer edge of the code wheel. The magnetic sensor senses changes in magnetic polarity when the poles pass by. The end result is the same as the output circuit outputs pulses to a PLC or HMI. Since there's no need to power the light emitter and receiver, the magnetic encoder uses less power than an optical encoder.

Magnetic encoders are more robust than optical encoders in the sense that they can operate better in humid, dusty, or dirty environments. However, magnetic encoders may not work well in an environment with magnetic interference. Magnetic encoders are also offered in rotary, linear, incremental, and absolute types. To enable a magnetic encoder to track absolute positions, multiple magnetic disks are necessary.

| Round Shaft Type | Hollow Shaft type | |

|---|---|---|

| Mounting dimensions: φ30 mm |  |

|

| Mounting dimensions: φ40 mm |  |

|

Dustproof and Water-Resistant IP65 Type

This product is dustproof and water-resistant to IP65 standards, meaning it can be used without being affected by dust or water droplets. No cover is required, and it can be installed as is.

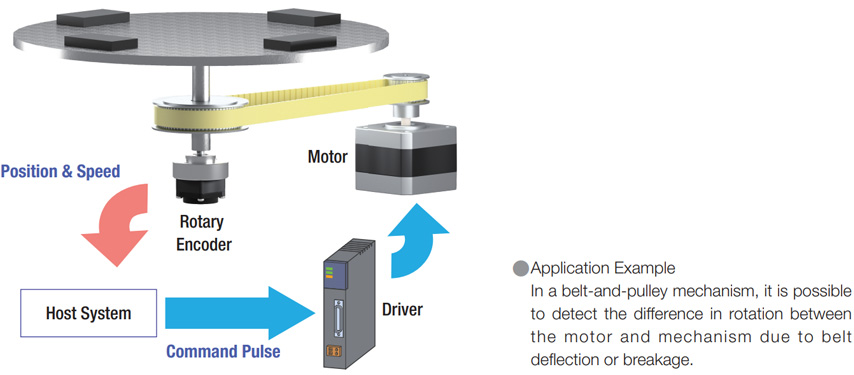

Actual Position, Speed and Rotation Direction of the Mechanism can be Detected

By installing a rotary encoder on a mechanism, a preventative maintenance system for that mechanism can be created.

Can Be Installed to Suit the Mechanism

By installing a rotary encoder on a mechanism, a preventative maintenance system for that mechanism can be created.

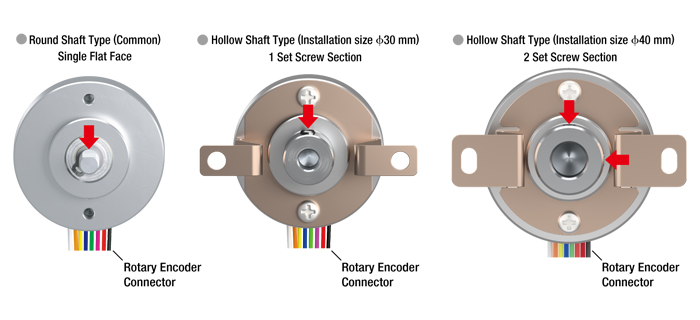

Aligning Mechanical Home and Z-Phase Signal Position is Easy

The Z-phase signal is output at the position where the shaft flat (round shaft type) or the fixing screw (hollow shaft type) has rotated 180˚ from the encoder connector. Use this as a guide when aligning the mechanical home and the Z-phase signal position.

Product Lineup

Encoder |

Output Shaft Type |

Resolution (P/R) |

Open Circuit Type |

Degree of Protection |

Round Shaft Hollow Shaft |

100~4000 |

Voltage Line Driver Open Collector |

IP20 |

|

IP20 IP65 |

Encoder Connection Cable

Use the encoder connection cable to connect to the host controller.

Mounting Bracket (for 30 mm Round Shaft Type Only)

The round shaft type rotary encoder can be installed by using the mounting bracket.

Product Number

Applications

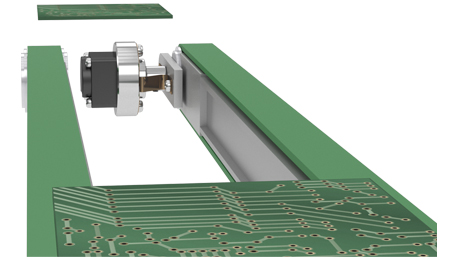

Conveyor

Measure the speed, position, and direction of the belt.

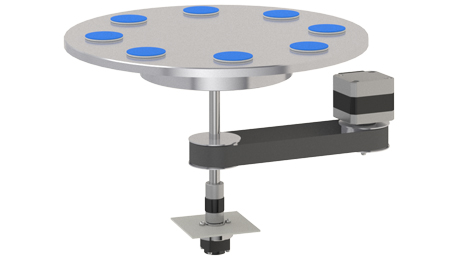

Index Table

Detecting the position of the index table.

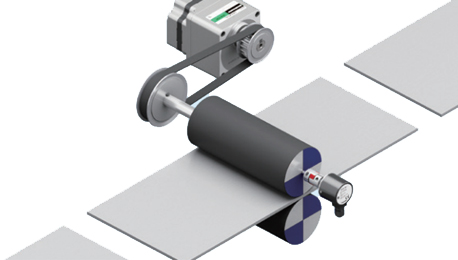

Roll Feed

Precisely measure feeding lengths.

Winding

Eliminate slacks in winding.