Speed Control Motors

Speed Control Motors

For applications where variable speeds are necessary, typically an AC motor with an Inverter or brush motors are used. Brushless DC motors are an advanced option due to their wide speed range, low heat and maintenance-free operation. Stepper Motors offer high torque and smooth low speed operation.

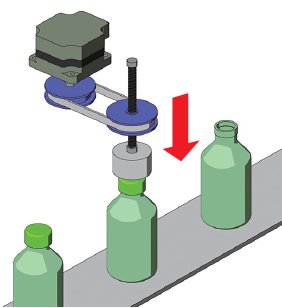

Speed is typically controlled by manual operation on the driver or by an external switch, or with an external 0~10 VDC. Speed control systems typically utilize gearheads to increase output torque. Gear types range from spur, worm or helical / hypoid depending on torque demands and budgets.

Mounting configurations vary to depending on space constraints or design of the application.

Choosing the Right Motor: AC Gear Motor vs. Brushless DC Motor, Which is Better?

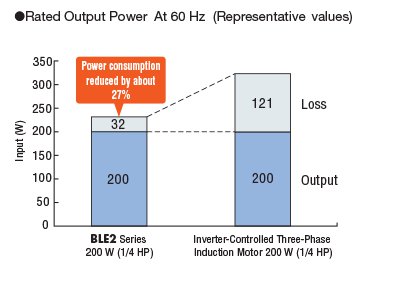

Low Heat / High Efficiency

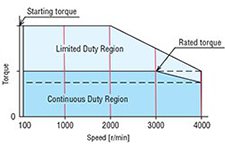

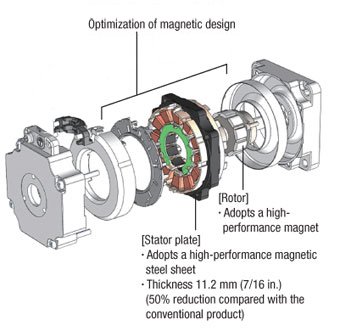

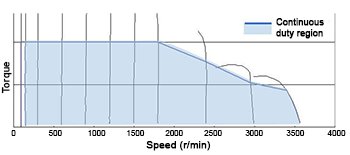

Brushless DC motors use permanent magnets in the rotor and produce low heat due to their high efficiency, are cleaner and are maintenance free because there are no brushes to replace. Brushless DC motors offer 80-4000 r/min with a flat torque curve allowing for constant speed with varying loads.

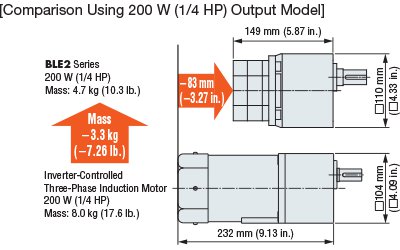

Motor Footprint

Brushless DC motor’s torque density is higher than AC gear motors, allowing for a more compact design. Using hall effect sensors allows for closed loop control and maximum design flexibility.

Speed Control Motor Comparison

Brushless DC Motors and Drivers

Brushless DC Motor Comparison

Product Series

|

||||||||

|

||||||||

Features |

Advanced Performance Torque Control Digital Display 4 Speed Setting Methods |

Easy-to-Use Simple Set Up and Wiring Digital Display |

High Performance Speed, Positioning and Torque Limiting Control Multiple Speed Setting Methods |

Standard or RS-485 Communication Type Drivers Torque Limit Function |

Standard or RS-485 Communication Type Drivers Simple, compact, and cost-effective Reduces electricity costs Ideal for applications like conveyors and agitators |

Compact Board Type Driver Torque Limiting |

Battery Operated Compact Driver (Modbus RTU, CANopen) Driver |

Network Communications (I/O or RS-485) Torque Limiting |

Output Power |

30 W (1/25 HP) |

30 W (1/25 HP) |

30 W (1/25 HP) |

30 W (1/25 HP) |

25 W (1/30 HP) |

15 W (1/50 HP) |

100 W (1/8 HP) |

100 W (1/8 HP) |

Power Supply |

Single-Phase 100-120 VAC |

Single-Phase 100-120 VAC |

Single-Phase 100-120 VAC |

Single-Phase 100-120 VAC |

24 VDC |

24 VDC |

24 VDC |

24 VDC |

Gear Types |

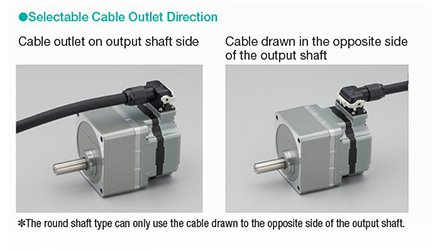

Parallel Shaft H1 Food-Grade Parallel Shaft (Foot Mount) Parallel Shaft (IP66 Stainless Steel Shaft) Right-Angle Hollow Shaft (IP66 Stainless Steel Shaft) Hollow Shaft Flat Gear Round Shaft (no Gear) |

Parallel Shaft H1 Food-Grade Parallel Shaft (Foot Mount) Parallel Shaft (IP66 Stainless Steel Shaft) Right-Angle Hollow Shaft (IP66 Stainless Steel Shaft) Hollow Shaft Flat Gear Round Shaft (no Gear) |

Parallel Shaft Hollow Shaft Flat Round Shaft (no Gear) |

Parallel Shaft Hollow Shaft Flat Round Shaft (no Gear) |

Parallel Shaft Hollow Shaft Flat Round Shaft (no Gear) |

Parallel Shaft Hollow Shaft Flat Round Shaft (no Gear) |

Parallel Shaft Hollow Shaft Flat Round Shaft (no Gear) |

Parallel Shaft Hollow Shaft Flat Round Shaft (no Gear) |

Available Options |

Electromagnetic Brake IP66 & IP67 Types |

IP66 & IP67 Types |

Electromagnetic Brake |

Electromagnetic Brake IP65 Type |

IP65 & IP40 Types |

Electromagnetic Brake |

Electromagnetic Brake |

Electromagnetic Brake |

Torque Setting |

Yes |

- |

Yes |

Yes |

Yes |

Yes† |

Yes |

Yes |

Monitoring |

Yes |

- |

Yes |

Yes |

Yes |

Yes† |

Yes |

Yes |

# of Speed Settings |

16 settings |

4 settings |

16 settings |

16 settings |

2 settings |

2 settings 8 settings |

8 (with direct/discrete) 256 (with remote inputs) |

2 settings 8 settings* (with Control Module or Support Software) |

Speed Control Range |

80 ~ 4000 r/min |

80 ~ 4000 r/min |

2 ~ 4000 r/min |

100 ~ 4000 r/min 80 ~ 4000 r/min |

100 ~ 4000 r/min |

100 ~ 3000 r/min |

1 ~ 4000 r/min |

100 ~ 4000 r/min |

Rated Torque |

0.85 to 5159 lb-in |

0.85 to 5159 lb-in |

0.89 to 970 lb-in |

0.85 to 600 lb-in |

0.85 to 575.3 lb-in |

0.44 to 600 lb-in |

0 ~ 470 lb-in |

5.75 to 970 lb-in |

Learn More |

Features of Brushless DC Motors

Our new brushless DC motor allows for maximum design efficiency with an AC input driver selection. Designed to meet an IP66 rating, inch or metric, stainless steel gear shafts, one motor cable connection and a wide variety of wattages and gear types are offered to meet industrial needs.

Brushless DC Motors offer built-in Hall Effect sensor feedback for speed verification to maintain closed-loop speed regulation. In addition to controlling the motor speed, torque limiting (BLE2) and speed range limit setting, the drivers also offers an alarm function in case any problem occurs during operation.

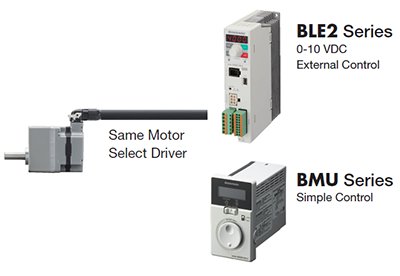

Same Motor / Select Driver

The new brushless DC motors (BLE2 and BMU) feature the same motor with two driver options based on your application needs.

New Design (BLE2 and BMU Series)

IP66 Degree of Protection

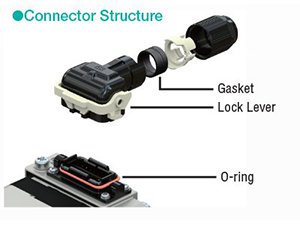

Utilizing an industry style compact connector, a direct connection between the motor and driver can be achieved, no secondary connections. Connection is easy with the lock lever that does not require screws.

Standardized Stainless Steel Shaft

SUS303 type steel, which provides excellent rust prevention and corrosion resistance. Stainless steel is also used in the parallel keys and installation screws

Gearing Options

Parallel Shaft- GFV Gear |

Parallel Shaft - JV Gear* |

Parallel Shaft (Foot Mount)* |

Right-Angle Hollow Shaft* |

|

|

|

|

30 W (1/25 HP) |

200 W (1/4 HP) |

200 W (1/4 HP) |

120 W (1/6 HP) |

Gear Ratios: 5, 10, 15, 20, 30, 50, 100, 200 |

Gear Ratios: 300, 450 |

Gear Ratios: 5, 10, 20, 30, 50, 100, 200, 300, 450, 600, 1200 |

Gear Ratios: 10, 15, 20, 30, 50, 100, 200 |

Rated Torque up to 483 lb-in |

Rated Torque up to 3800 lb-in |

Rated Torque up to 5150 lb-in |

Rated Torque up to 1575 lb-in |

*Available on the BLE2 and BMU Series

Inverters with Three-Phase Gear Motors

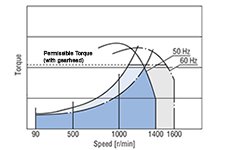

AC gear motors with inverters allow for simple speed control by changing the input frequency or input voltage.

Our KIIS Series has been optimally designed for accurate speed control. For larger motor needs, our Brother ie3 motors offer high efficiency motors with Hypoid / Helical gearheads in parallel or right angle mounting configurations.

For smaller, compact closed loop applications (6 - 90W), Oriental Motor offers a closed loop package (DSC Series). For larger (100-200W up to 3 HP) requirements, our Three-Phase AC motors with a Frenic-Mini C2 Inverter is ideal.

Inverter Specifications

Series |

|

|

|

Features |

Auto-Tuning |

Speed Control Motor |

Sold Separately |

Compatible Motors |

1/8 HP (90 W) |

Input Voltage |

Single-Phase 100~120 VAC |

Gear Options |

Parallel Shaft (Foot or Flange Mount) |

Analog/Digital Speed Setting |

Yes |

Parallel Operation |

Yes |

Electromagnetic Brake Control |

Yes |

# of Speed Settings |

16 |

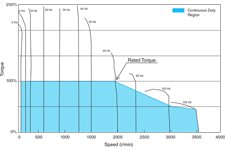

Speed & Torque Characteristics |

|

Learn More |

AC Motor Comparison

Product Series |

|||

|

|

|

|

|

Features |

High Torque High Speed High Efficiency Speed Stability Designed for Inverters/VFD's |

High Torque ie3 Efficiency Efficient Hypoid Gear Electrocoat Paint Stainless Steel Shaft |

Watertight Dust-Resistant Oil Shield Protection Anti-Corrosive Epoxy Coating Stainless Steel Shaft |

Output Power |

100 W (1/8 HP) |

400 W (1/2 HP) |

90 W (1/8 HP) |

Voltage |

Three-Phase 200-230 VAC |

Three-Phase 208/230/460 VAC |

Three-Phase 200/220/230 VAC |

Available Options |

IP66 Rated |

IP65 Type |

IP67 Rated |

Rated Torque |

5 to 1,680 lb-in |

81 to 11,188 lb-in |

12.3 to 260 lb-in |

Learn More |

Fuji Electric FRENIC-Mini (C2) Inverters / VFD

The new user friendly FRENIC-Mini (C2) inverters elevates the performance of a wide range of equipment.

For use with 1/8 HP up to 3 HP Three-Phase Motors

Single-Phase 115 VAC or 230 VAC input, Three-Phase 230 VAC or Three-Phase 460 VAC input.

Standard functions:

- Auto-Tuning / Torque Boost

- Flexibly Remote / Local Operation

- Dynamic Torque Vector Control

- Fastest CPU in its Class

- Network Compatibility

- Efficiency Setting / Side by Side Mounting

KIIS Series Three-Phase AC Induction Motors

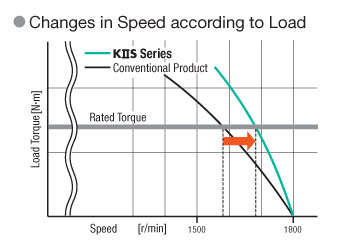

The Three-Phase KIIS Series offers an optimally designed, high efficiency next generation Three-Phase motor that incorporates higher strength gears, both Parallel Shaft type and new Hypoid Right Angles type that maximizes the motor performance. The KIIS Series is available from 100 W (1/8 HP) up to 200 W (1/4 HP) and features either a parallel or hypoid pre-assembled gear head.

High Performance

Characteristics have been improved to create a high-performance motor with little speed reduction even with a large load.

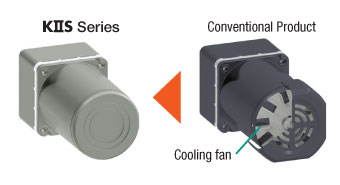

Fanless Design

KIIS new motor design reduced heat generation. With higher efficiency there is less heat generation in the motor so a cooling fan on the back of the motor is no longer required. With no cooling fan, dust is not blown around.

Brother Gearmotor AC Induction Motors

These AC gear motors feature superior efficiency from hypoid or helical gears while offering greater torque output thereby allowing for smaller motors and greater energy saving.

The gears in these AC gear motors are high strength, maintenance free and can be mounted in any direction with their slip fit "O" ring design. High reduction ratios, flange mount or foot mount types, right angle or hollow shaft right angle types available.

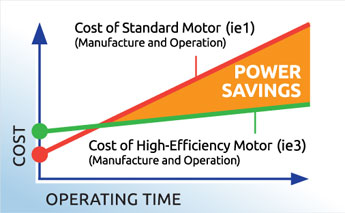

Premium Efficiency Series ie3

The new ie3 premium efficiency gear motors cost less to operate and demonstrate clear benefits when running for long periods of time (when compared to ie1 standard efficiency gear motors).

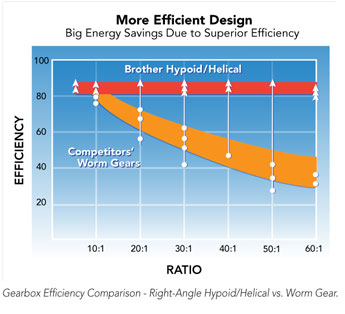

High-Efficiency Hypoid / Helical Gearheads

Compared to commonly used worm gears, High efficiency gear motors feature Hypoid / Helical gearing technology that can maintain efficiency above 85% throughout the motor's wide speed range.

FPW Series IP67 Washdown AC Gear Motors

The FPW Series are washdown AC induction gear motors ideal for applications where they are splashed with water. All FPW Series washdown AC gear motors conform to the IEC standard IP67 (Recognized by UL). Each washdown motor and gearhead comes pre-assembled with gear ratios from 3:1 to 180:1.

Designed and Constructed for Watertight and Dust Resistance

Improved Anti-Corrosion Properties

High corrosion resistance is achieved through special anti-corrosive coating and re-examination of shaft material [stainless steel (SUS303 type)].

Conforms to Major Safety Standards and Global Power Supply Voltages

The FPW Series washdown gear motor is recognized by UL and CSA and certified under the China Compulsory Certification System (CCC System). CE Marking is used in accordance with Low Voltage Directive. Additionally, our wide range of products include those that meet the power supply voltages of major countries in Asia, North America and Europe.

Speed Control Stepper Motors

CVK-SC Series Speed Control Stepper Motors

The CVK Series SC speed control system offers a simple configuration consisting of a stepper motor, driver and programmable controller. The operating speed, acceleration and deceleration time, running current can be set via the driver switches, and simply turning the FWD (RVS) input to ON or OFF allows for easy control.

- No pulse generator needed

- 2 speed settings are possible

- Compact and high torque stepper motor

- Improved stop position repeatability

- Maintains torque even when stopped

- Continous duty is possible

Typical Applications

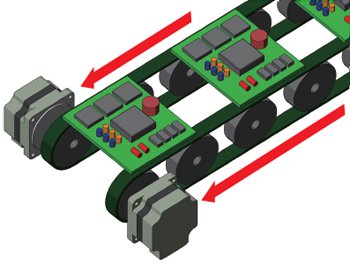

Conveyors

Multiple Loads with Different Weights

Speed Stability can be maintained with flat torque (Brushless DC Motors)

2 Axes Parallel Speed Synchronization

Easily synchronize two motors / conveyors for simple speed control. (Brushless DC Motors)

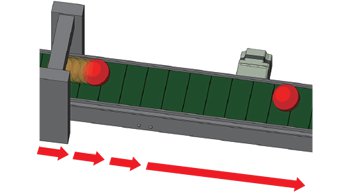

Variable Speed Conveyor

Speed can be slowed down to pass through specific function and sped up to increase throughput.

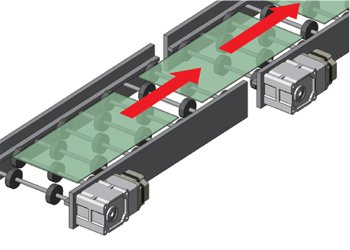

Set Stable Speed for Maximum Line Flexibility

Use speed control to maintain speed, adjusting for different processes. Maximum line flexibility.

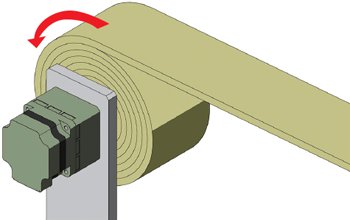

Take Up

Linear speed changes with external DC voltage

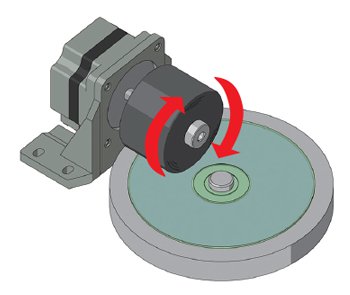

Grinding / Deburring

Variable speed depending on material

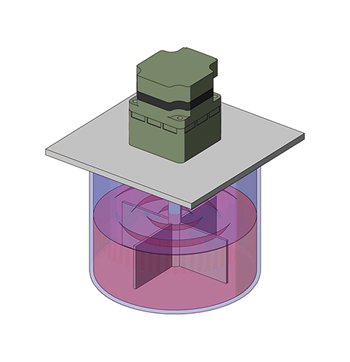

Stirring / Pump / Dispensing

Variable speed depending on process

Viscosity (load) changes, flat torque maintains speed, simple on / off or load holding (Brushless DC Motors)

Torque Sensing (BLE2 with torque limit function)

Monitor load or limit torque