Medical Case Study – Compact Stepper Drivers for Space Savings

Compact OEM Drivers for Advanced Performance and Space Savings

To save space and reduce costs, it has been common to design, test, manufacture, and rely on in-house designed stepper motor drivers. However, many manufacturers have found that this approach can lead to increased vibration, noise, and other performance challenges as they move standard architecture to newer projects and applications. Another issue with this approach can be the increasing number of electronic components becoming difficult to obtain, making it difficult to procure them, especially since the IC used in the in-house designed drivers leads to production delays. Although ICs can be changed to one from a new manufacturer, quality issues and testing have arisen, leading to a BCP (Business Continuity Plan).

Challenge:

- High Performance at a Reasonable Price

- Standardization

- Quality for a Wide Variety of Axes Considerations

- Space Savings

- Stable Supply

- OEM Products, Reducing Assembly Time

Solution:

- Stable procurement of drivers and reduction of maintenance parts

The CVD Series S type comes pre-installed with the components necessary to drive the motor, such as a microcontroller, FET, current detection resistor, fuse, etc. By simply connecting an aluminum electrolytic capacitor, you can complete a drive circuit similar to that of an off-the-shelf product.

Reducing the number of required parts will also simplify the management of maintenance parts after operation begins.

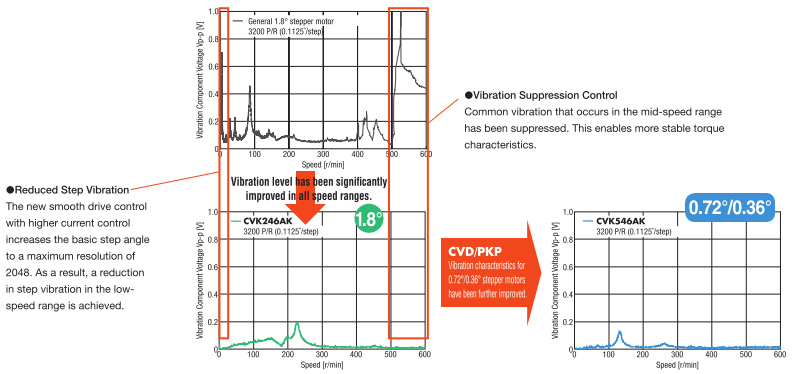

Specially Designed Motor Characteristics Are Brought Out to Achieve High Torque, Low Vibration, and Low Noise

The CVD Series is designed to maximize the motor characteristics of the PKP Series stepper motor, achieving high torque by increasing the output current, while reducing vibration and noise through full-time microstep control, contributing to improved performance such as quieter equipment.

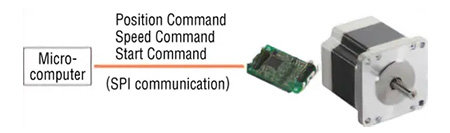

No Pulse Generation IC is Required, and Positioning Control is Possible via SPI Communication

The CVD Series S Type supports SPI communication, allowing direct control of position and speed settings, motor start/stop, and more via SPI communication. There's no need to use a CPU to generate pulse signals instead of a pulse generation IC. This reduces the cost of the pulse generation IC while also easing the burden of generating pulse signals.

When Using CVD Series S Type SPI Communication Compatibility |

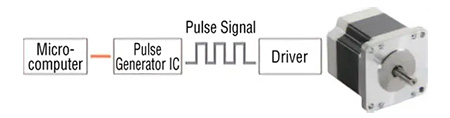

When Using Pulse Generator ICs |

|

|

Reduce Load on Host Controller

The CVD Series S Type can directly capture signals from the encoder. By comparing with the number of pulses from the host controller, it can be used to check for malfunctions due to noise, reducing pulse counters and calculation systems.

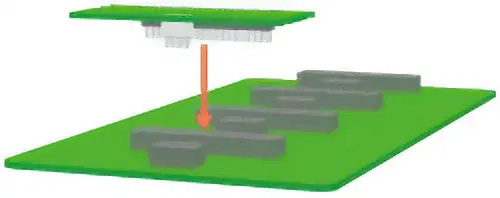

Direct Mounting of Drivers on Electronic Boards Reduces Design Time

The CVD Series S Type is designed for direct mounting on electronic boards. This eliminates the need for additional adapters, etc., and reduces design work time.

Image of Direct Mounting on an Electronic Board

CVD Series S Type Product Line up

Stepper Motor Drivers |

Driver |

Current |

Motor Types |

Power Supply |

|

|---|---|---|---|---|---|

Board Mounting Type |

I/O Setting |

0.5 ~ 2.8 A/Phase |

2-Phase |

24 VDC |

|

SPI Communication |

|||||

Board Mounting Type |

I/O Setting |

0.5 ~ 2.8 A/Phase |

2-Phase |

24 VDC |

|

SPI Communication |

|||||

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-468-3982