Discover the Advantage and Benefits of Brushless DC Motors

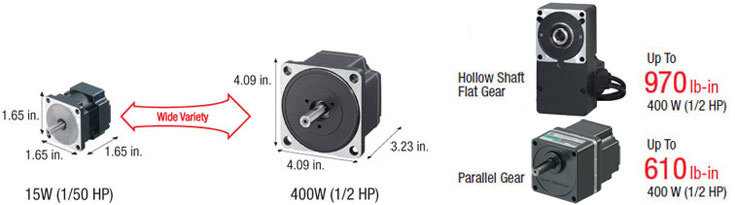

Brushless DC motors from Oriental Motor can achieve up to 5159 lb-in of torque when combined with a standard geared option. Their space saving design contributes to a compact and powerful solution ranging from 15 W up to 400 W. Their flat torque characteristics can produce the same rated torque at wide speed range. Brushless DC Motors (BLDC Motors) also feature a wide variety of geared and electromechanical brake options and are available with our industry leading stable lead times.

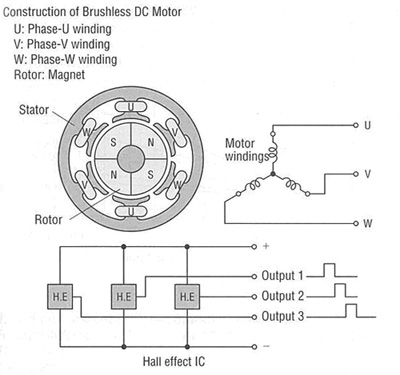

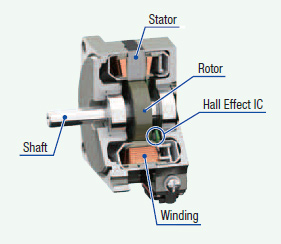

Brushless DC Motor (BLDC Motor) Construction

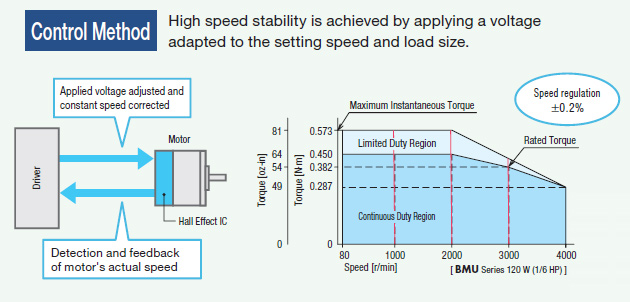

Brushless DC motors use permanent magnets in the rotor of three-phase motors. In addition, on the inside of the stator, there is a built-in hall effect IC (magnetic sensor) that detects magnetic field changes with the permanent magnets, The feedback signals from the hall effect IC of the motor are compared with the setting speed by the driver and the motor speed is adjusted continuously.

The brushless DC motor features a coil is star-wired (Y-wired) with three-phases: U, V, and W and is located in the stator, and the rotor is made of magnets magnetized in a multi-pole configuration as shown in Fig. 1.

Inside the stator, three hall ICs are arranged as magnetic elements so that the phase difference of the output signal from each hall IC will be 120 degrees apart for every rotation of the rotor.

Compact Yet Powerful

Brushless DC Motors (BLDC Motors) are very compact and when mated with a gear head, can produce a large amount of torque.

Excellent Speed & Torque Performance

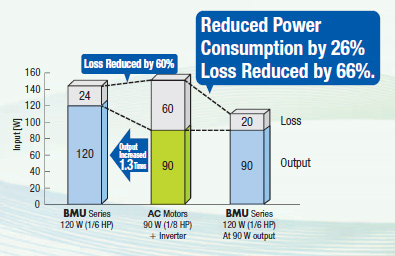

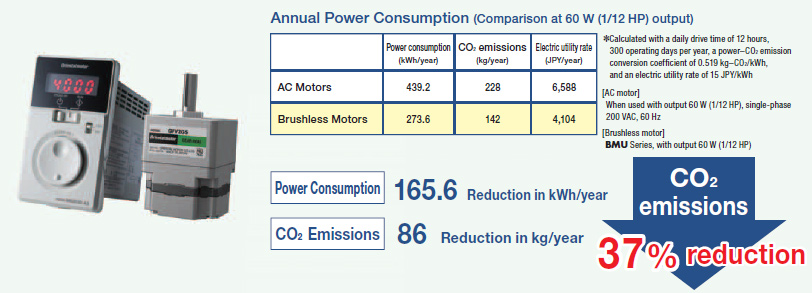

Energy Saving

Brushless DC (BLDC) motors, which incorporate permanent magnets in the rotor, generate little secondary loss from the rotor.

At an output power of 1/6 HP (90 W), for example, the power consumption of the BMU Series Brushless DC Motor is approximately 26% less than that of an inverter-controlled AC motor, which enables the energy-saving operation of your equipment.

No Brushes = No Maintenance

The Brushless DC Motors (BLDC Motors) do not utilize brushes, which often require replacing and/or maintenance, saving time and cost.

High efficiency is achieved with a highly magnetic permanent magnet in the rotor.

Energy Savings When an AC Motor is Replaced with a Brushless DC Motor

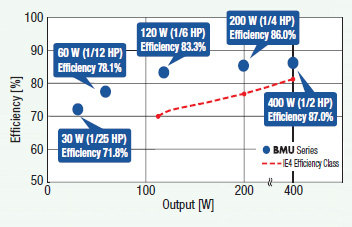

IE4-equivalent* High-Efficiency, Energy-Saving Motor

Brushless motors with a built-in permanent magnet are more efficient than three-phase motors (induction motors). For example, the BMU Series 200 W (1/4 HP) increases motor and driver efficiency by 86% and the IE4 standard value by 75.8%, meeting energy saving requirements.

*The efficiency class stipulated in the international standard IEC60034-30-1, to which 120 W (1/6 HP) and higher induction motors are subject.

*The IE4 efficiency value is the value at the rated output power of a 50 Hz, four-pole device. The efficiency value of a brushless motor is the value at rated torque at rated speed.

BMU Series Brushless DC Motors (BLDC Motors) (AC Input)

Easy Speed Control

Using the dial and digital speed indicator, controlling the BMU series brushless DC motor speed is simple and user-friendly.

Turn the dial and set the desired speed. Push to set (store) the desired speed. After the speed has been set, it can easily be changed by operating the dial. The dial can be locked to prevent changes in speed with the dial lock operation.

Easy Wiring, Easy Set Up

Get started quickly and easily. Connecting the motor is simple using the included cables with connectors. The power and I/O connectors feature a screwless connector, eliminating the need for soldering or crimp tools. Start the motor with one switch; the motor starts when the switch is set to "RUN" and decelerates to a stop if set to "STAND-BY". It's also simple to change the rotation direction of the motor using the rotation direction switch on the front of the driver.

Easy to Use Digital Controller

(Typical functions that can be set while the front panel is opened)

- Motor Start/Stop*

- Adjusting the operating speed*

- Setting the operating speed*

- Selecting the rotation direction*

- Changing the indication

- Indicating the operating speed when the speed reduction/speed increasing

ratio is set - Setting the acceleration/deceleration time

- Dial operation lock

- Speed setting for the 4-speed operation

- Speed limits setting

- Validating the external operating signals

- External input/output signal allocation

- Setting the overload alarm detection time, except during axial lock

- Load holding function for output shaft

*Setting is possible even if the front panel is attached.

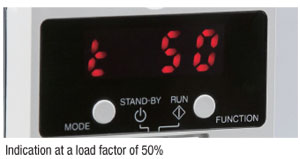

Load Factor can be shown

With the rated torque of the motor at 100%, the load factor can be expressed as a percentage (40-200%). The load condition during start-up, as well as the load condition due to the aging deterioration of the equipment can be confirmed.

Dial Operation Lock Function

This prevents the undesired changes in the speed and the changes or deletion of data with the operation of the dial. At the main screen for each operating mode, press the "MODE" key for 5 seconds or more. When "Lk" appears the lock function is activated.

Canceling the Lock Function

Return to the main screen and press the "MODE" key for 5 seconds or more. When "UnLK" is indication the lock function has been cancelled.