Speed Control AC Motors & Gear Motors - US2 Series

Speed Control AC Motors & Gear Motors - US2 Series

Advanced performance and reliability with unique Oriental Motor technology. Extremely user-friendly and a stylish appearance. The US2 Series is a product that is recommended for both first-time customers, as well as all customers who want to continue using speed control motors.

- Compact and Cost Effective

- Easy Operation, Simple Wiring

- Closed loop system for reliable performance and improved speed regulation

- High Torque, Long Life AC Gear Motors: 6 W (1/125 HP) ~ 90 W (1/8 HP)

- Imperial or Metric Geared Output Shafts

- Power Cable and Capacitor included

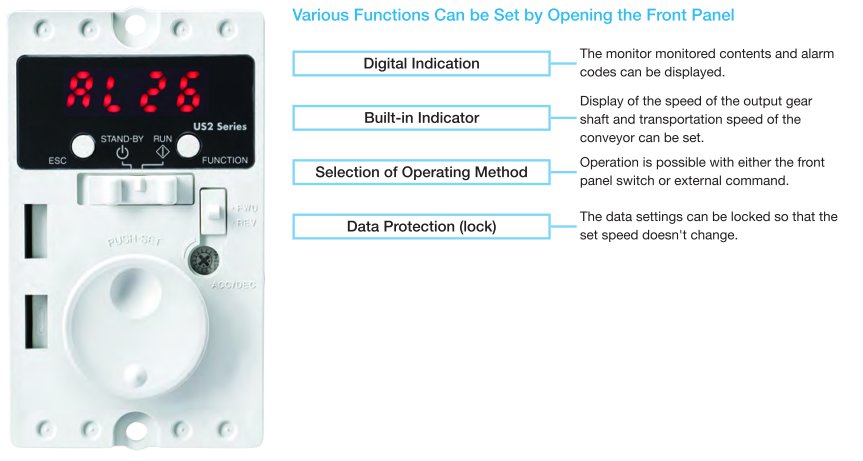

Easy Operation

Operate by Turning the Dial and Pressing

Turn the dial and set to the desired value. Set the speed by pressing the dial.

Start, Stop and Switching the Rotation Direction

Starting/stopping and switching the rotation direction is done with a single switch operation. No external switches need to be provided.

High Reliability

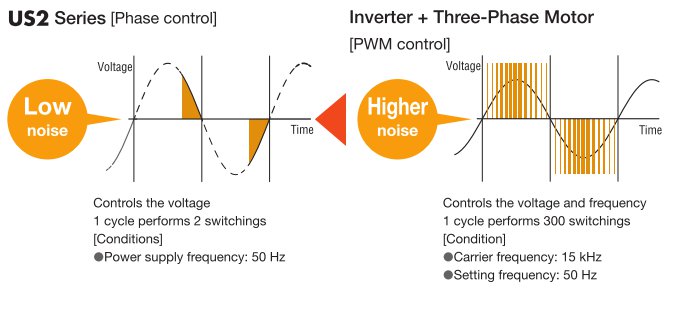

Low Electrical Noise and Simple System Configuration

The motor and speed controller used in the US2 Series do not generate a lot of noise themselves. This means that little peripheral equipment is needed to suppress noise, which cuts down on equipment labor and costs and saves space.

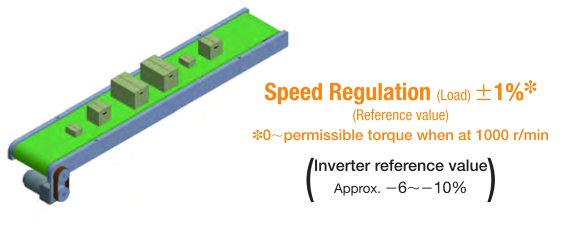

Speed Control Using Closed Loop Control

Stable Operation Even if the Load Fluctuates

The tachogenerator built into the AC motor always checks the speed, so the setting speed is always maintained even if the load fluctuates. In addition, due to this switch to a digital control circuit, speed regulation has been improved from −5% to ±1%*.

Simple Wiring

Max. Extension Length 32.8 ft. (10 m)

Connecting the motor and speed controller is easy using a connector. The motor and speed controller can be up to 32.8 ft. (10 m) apart.

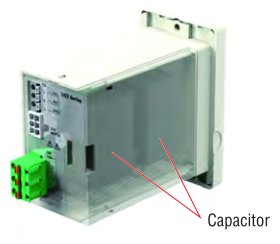

Built-In Capacitor

Since the capacitor is built in, wiring labor is reduced and space is not wasted.

Useful Functions

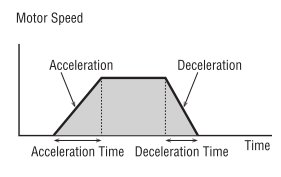

Smooth Operation when Starting and Stopping

The motor's acceleration time and deceleration time can be set with the acceleration/deceleration time potentiometer.

Setting time 0.1~15 seconds (the factory setting is 1 second)

- The acceleration/deceleration time potentiometer must be enabled with the

FUNCTION key in advance. - The instantaneous stop function is not available.

Protection for Motor and Speed Controller

Alarms for the motor overheating, poor connection, locking, etc. are displayed to protect the motor and speed controller.

Use of High Permissible Torque, High Strength Gearhead

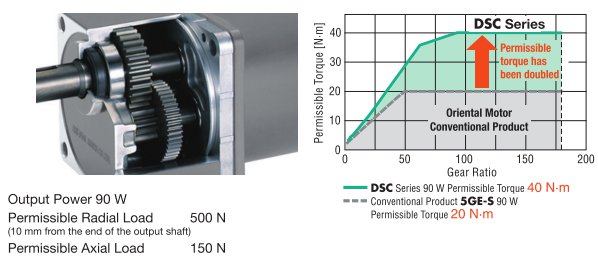

Parallel Shaft Gearheads

Utilizes a gearhead that excels in both permissible torque and strength. Special side panels in the gearhead have increase rigidity, and heat processing (carburization) has increase the strength of the gears.

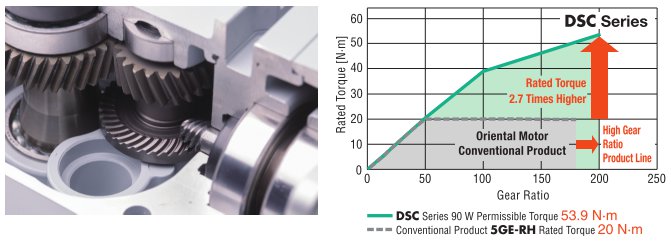

Right-Angle Hollow and Solid Shaft Gearheads

- 25 W (1/30 HP)

- 40 W (1/19 HP)

- 90 W (1/8 HP)

Uses high-strength hypoid gears. Compared to conventional products, torque has been greatly increased and noise has been reduced. Furthermore, the radial load and axial load on the gearhead output shaft have been increased, contributing to decreased equipment size and increased reliability.

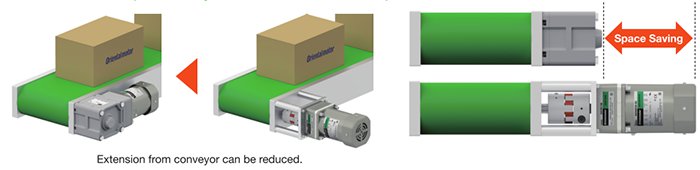

Motor Mounted Perpendicularly to the Drive Shaft, Saves Space

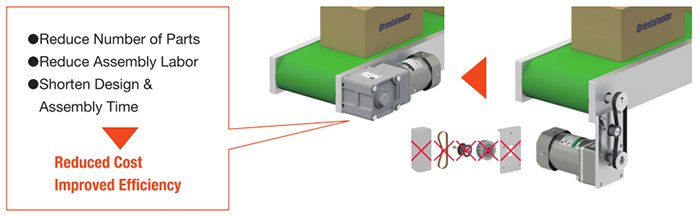

Connect Directly to the Drive Shaft to Reduce Costs

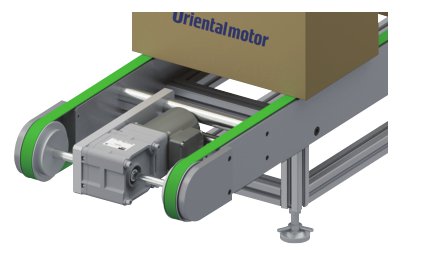

Installation Inside Conveyor Provides FurtherSpace Savings (Hollow Shaft Type)

Conveyor drive rollers can be installed on both ends of the load shaft of a hollow shaft type. The equipment can be made even smaller compared to when the motor is installed on the side of the conveyor.

Preassembled Motor and Gearhead

Reduces customer assembly time, and can be installed on equipment immediately.

The motor position can be rotated in 90° increments, and the lead wire pull-out direction can be changed. The gearhead can be purchased and replaced for maintenance or to change the gear ratio.

Use of a torque arm allows for even further time and labor savings for installation

Speed Control Motor Lineup

Output Power |

Gear Types |

Power Supply |

Permissible Torque* |

Variable Speed Range* |

|

Parallel Shaft |

Single-Phase 110/115 VAC |

2 ~ 53 lb-in |

0.23 ~ 6 N·m |

90 ~ 1600 |

|

Round Shaft (no Gear) |

7.1 oz-in |

50 mN·m |

|||

Parallel Shaft |

Single-Phase 110/115 VAC |

4.9 ~ 88 lb-in |

0.54 ~ 10 N·m |

90 ~ 1600 |

|

Round Shaft (no Gear) |

17.7 oz-in |

125 mN·m |

|||

Parallel Shaft |

Single-Phase 110/115 VAC |

8.1 ~ 141 lb-in |

0.92 ~ 16 N·m |

90 ~ 1600 |

|

Right-Angle Hollow Shaft |

8.8 ~ 181 lb-in | 1.0 ~ 20.5 N·m | |||

Right-Angle Solid Shaft |

|||||

Round Shaft (no Gear) |

29 oz-in |

205 mN·m |

|||

Parallel Shaft |

Single-Phase 110/115 VAC |

12.3 ~ 260 lb-in |

1.4 ~ 30 N·m |

90 ~ 1600 |

|

Right-Angle Hollow Shaft |

14.1 ~ 310 lb-in | 1.6 ~ 35.2 N·m | |||

Right-Angle Solid Shaft |

|||||

Round Shaft (no Gear) |

45 oz-in |

320 mN·m |

|||

Parallel Shaft |

Single-Phase 110/115 VAC |

19.4 ~ 260 lb-in |

2.2 ~ 30 N·m |

90 ~ 1600 |

|

Round Shaft (no Gear) |

69 oz-in |

490 mN·m |

|||

Parallel Shaft |

Single-Phase 110/115 VAC |

29 ~ 350 lb-in |

3.3 ~ 40 N·m |

90 ~ 1600 |

|

Right-Angle Hollow Shaft |

36 ~ 470 lb-in | 4.1 ~ 53.9 N·m | |||

Right-Angle Solid Shaft |

|||||

Round Shaft (no Gear) |

103 oz-in |

730 mN·m |

|||

*Torque and Speed vary based on input voltage and frequency, please review product specifications for details.

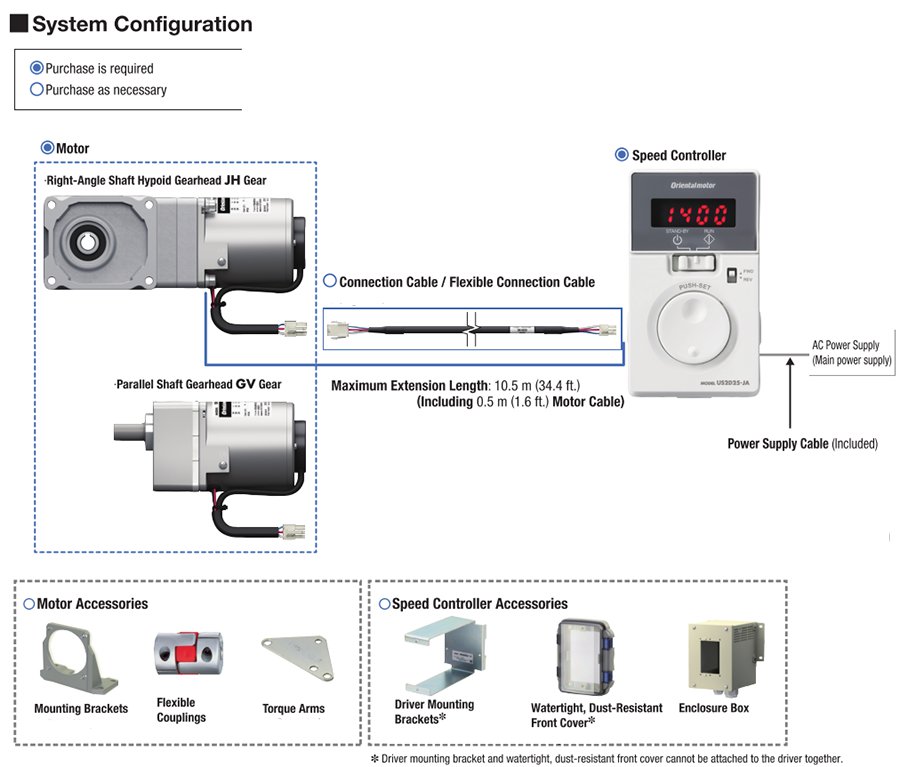

Connection / Extension Cables

These cables extend the distance between the motor and controller. Use flexible connection cable in applications where the cable is bent or flexed.

Front Panel Cover for Driver

Provides IP64 protection and prevents changes to the driver.

Driver |

Item |

US2 Series |

Driver Box

Driver Protection (IP20)

- Top or Rear Mount

- Provides protection from dust

- Electric shock protection (for wiring)

- Front cover (sold separately) to prevent accidental operation

Driver |

Item |

US2 Series |

PCD12 |

Driver Mounting Brackets

Driver mounting brackets.

Type |

Item |

| Panel Mount | |

| DIN Rail |

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

Mounting Bracket

This is an aluminum die cast mounting bracket for geared motors.

Long, horizontal holes make it easy to make fine adjustments during installation.

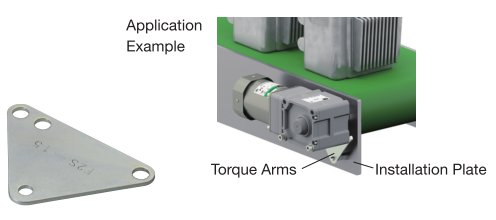

Torque Arm

A torque arm acts as an anti-spin mechanism when a right-angle shaft, hollow hypoid JH gear is installed to prevent gearheads from rotating due to reactive force from shafts being driven.

Output Power |

Item |

25 W (1/30 HP) |

|

40 W (1/19 HP) |

Power Cable

The Controller includes a Power Cable.

System Configuration

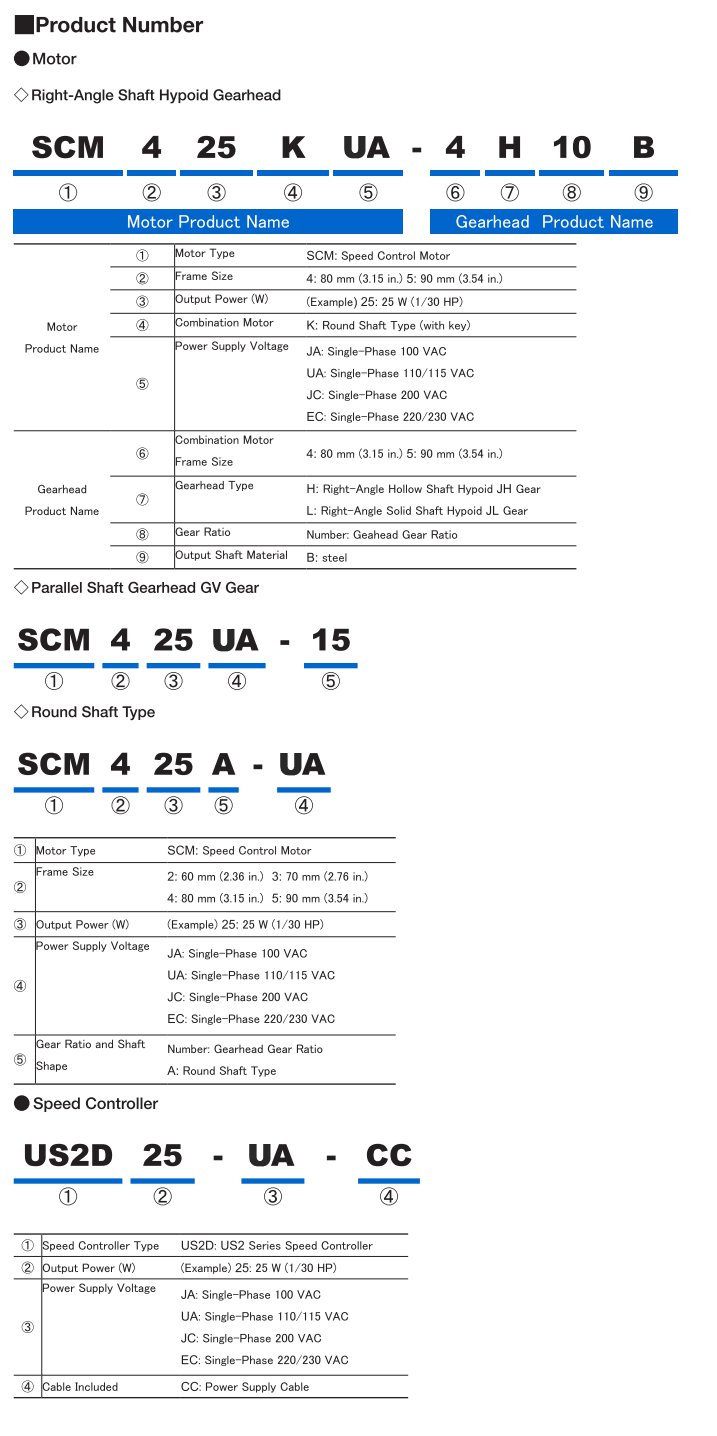

Product Number Code

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.