Medical Case Study - Compact Brushless DC Motors for Continuous Duty Pump Applications

Brushless DC Motors Reduces Noise and Improves Reliability in Dialysis / Infusion Units

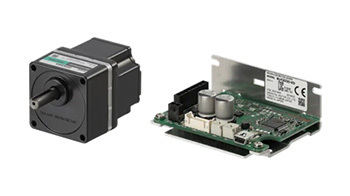

In patient settings, lab rooms, or other noise sensitive environments, having minimal noise while not sacrificing motor torque is important. This is also true for space saving requirements, as the footprint for most medical equipment needs to be as compact as possible. It is also important to minimize motor heat, as this helps reduce noise, since no cooling fans are required, and also contributes to long life and reliable performance. One case in point, using a BLH Series compact Brushless driver with a Brushless DC motor allows for consistent torque output, motion monitoring as the motor provides feedback to the driver, along with alarm outputs in the event of a problem.

Challenge:

- Quiet Operations

- Flat, Consistent Motor Output Torque

- Space Savings

- Reduced Heat

Solution:

- The BLH Series brushless DC motors are quieter and more reliable, creating a more comfortable medical environment.

In the operating environment of dialysis machines and infusion units, consideration of motor quietness and temperature rise is essential. The BLH Series brushless DC motors offer quiet operation and high-efficiency drive, achieving the quietness and reliability required in medical settings. In addition, an overload alarm is output from the driver in the event of an abnormality such as tube jamming, contributing to improved safety.

Reduced Heat Generation from the Motor Reduces the Thermal Impact on Infusion Fluids

Brushless DC motors use permanent magnets in the rotor, making them thin, lightweight, and powerful, with high torque output that is able to suppress heat generation. This prevents temperature rise even during long periods of continuous operation, minimizing the thermal impact on infusion fluids.

Sine Wave Drive Driver Reduces Drive Noise

The BLH Series uses a sine wave drive system, which applies a smooth motor current to reduce torque ripple and achieve lower noise levels. The drive noise is unnoticeable even in the quiet environment of a hospital, contributing to improved patient comfort.

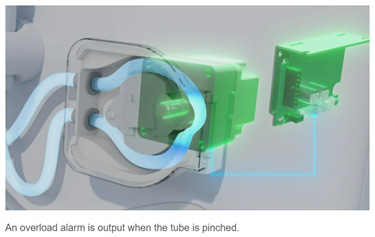

Improved Reliability of Equipment by Outputting an Alarm When an Overload Occurs

The brushless DC motors are equipped with a function that outputs a signal to the driver that will output an alarm in the event of an overload. This allows for real-time detection of load changes, such as jammed tubes or clogged piping. For example, if an abnormality such as an overload occurs, the motor stops and an alarm is output, informing that the equipment needs attention. This function prevents damage to equipment and tube breakage, ensuring highly reliable operation.

BLH Series Brushless DC Motors

- Suitable for continuous operation

- Reduce power consumption

- Stable flow rate due to speed regulation

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-468-3982