Medical Case Study - A Compact Linear Actuator for Medical Analyzer

A Compact Linear Actuator and Stepper Motor to Simplify Design and Improve Reliability

The need to turn rotary motor motion into linear motion for raising, lowering, dispensing or other applications while increasing reliability is a simple design is a challenge. To ensure a simple design, many have selected stepper motors with a built-in leadscrew. However, this can lead to overstressing the bearings within the motor, resulting in early failure rates.

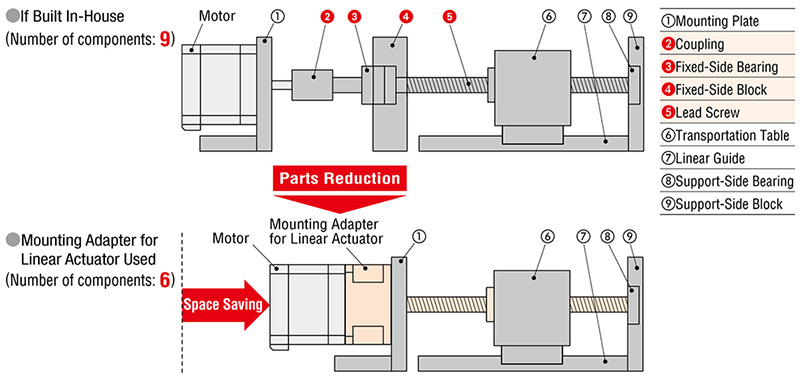

Designs have worked around this by using a leadscrew coupled to a motor. Assembly time is required for mounting and adjusting this mounting for accuracy because the motor is connected to the screw mechanism via a coupling.

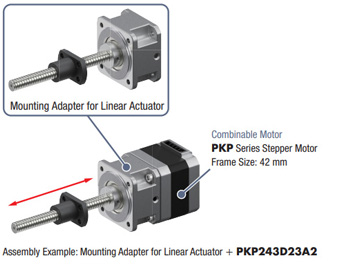

Revising the configuration requires a simple design that combines space savings with high reliability. Replacing the conventional complex mechanism with a linear actuator attachment that does not require coupling, and a 2-phase stepper motor with an encoder, enables stable operation while reducing assembly time.

Challenge:

- Increased Reliability

- Reduced Assembly Time

- Standardization

- Space Saving

- Quality Improvement

Solution:

- Linear Actuator Attachment Products and Motor With Encoder

Encoder Equipped Stepper Motors

Our standard type encoder resolution is available in 200, 400, and 1,000. With this semi-custom order, we have the resolutions ranging from 100 to 4,000 P/R.

Output Type: Incremental

Resolution (P/R): 100/200/360/400/500/600/720/800/1000/1800/2000/2500/3600/4000

Comparison of Number of Parts

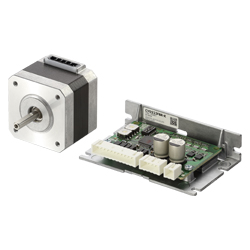

Wide Variety of Motors and Drivers to Provide More Reliable Motion

A motor equipped with additional features such as a built-in encoder, electromagnetic brake, and battery-free absolute encoder can be used in combination with a driver that provides low-vibration, low-noise operation, and FA network compatibility.

Combined Motor |

Built-in Battery-Free Absolute Encoder αSTEP AZ Series DC Power Supply Input |

2-Phase/5-Phase Stepper Motors PKP/CVD Series Driver |

| Frame Size |

|

|

| External View |  |

|

| Features |

|

|

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-468-3982