Medical Case Study - Stepper Motor with Encoder

Stepper Motor with Encoder to Save Space, Provide Feedback

Common to the industry, medical components require feedback. Encoders are regularly used to provide this feedback, from being mounted on a position axis or being mounted on the back of a stepper motor. Having a wide range of encoder resolutions available, mounted on the back of stepper motors from the OEM, provides time savings, cost savings, and ensures longer life. One of the important issues in developing medical equipment is how to reduce the space required. By using the PKP Series 2-phase stepper with an encoder mounted from the factory on the back of the motor, it is possible to achieve space savings in medical testing equipment. In addition, the number of parts required for each axis can be reduced, reducing the labor and costs required for encoder installation during mass production.

Challenge:

- Each Motor Requires Feedback

- Space Saving

- OEM Products, Reducing Assembly Time

Solution:

- Equipped with a small encoder

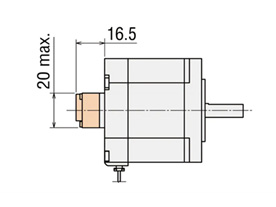

The encoder installed in the PKP Series 2-phase stepper motor with encoder is characterized by its high performance yet compact size. This product's encoder boasts high resolution and high angular accuracy, contributing to improved reliability of analysis results. Furthermore, for a stepper motor with a frame size of 56.4 mm, the encoder size is just 16.5 mm x 20 mm, making it extremely compact.

Standard & Semi-Standard Motors with Encoders

PKP Series Stepper Motors with Encoders

Our standard type encoder resolution is available in 200, 400, and 1,000. With this semi-custom order, we have the resolutions ranging from 100 to 4,000 P/R.

Output Type: Incremental

Resolution (P/R): 100/200/360/400/500/600/720/800/1000/1800/2000/2500/3600/4000

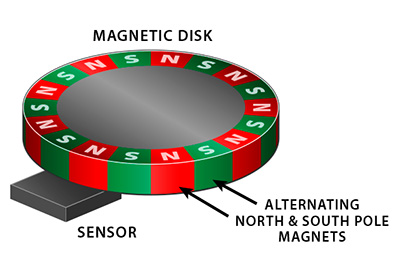

Magnetic Encoders

Magnetic encoders do not use a light emitter or a light receiver but still use a code wheel and a sensor. Instead of slits, the code wheel has alternating north and south pole magnets on the outer edge of the code wheel. The magnetic sensor senses changes in magnetic polarity when the poles pass by. The end result is the same as the output circuit outputs pulses to a PLC or HMI. Since there's no need to power the light emitter and receiver, the magnetic encoder uses less power than an optical encoder.

Magnetic encoders are more robust than optical encoders in the sense that they can operate better in humid, dusty, or dirty environments. However, magnetic encoders may not work well in an environment with magnetic interference. Magnetic encoders are also offered in rotary, linear, incremental, and absolute types. To enable a magnetic encoder to track absolute positions, multiple magnetic disks are necessary.

Stepper Motor Product Lineup

Frame Size |

Motor Types |

Available Options |

Current per Phase |

Lead Wires |

Max. Holding Torque |

|

Standard Type (1.8°) |

Encoder |

0.5 or 0.6 A |

4 |

2.8 ~ 5.1 oz-in |

0.02 ~ 0.036 N·m |

|

Standard Type (1.8°) |

Encoder |

1.5 A |

4 |

13.4 ~ 26 oz-in |

0.095 ~ 0.19 N·m |

|

High-Resolution (0.9°) |

Encoder |

12.2 ~ 23 oz-in |

0.086 ~ 0.165 N·m |

|||

Geared Type |

Encoder |

42.5 ~ 112 oz-in |

0.3 ~ 0.8 N·m |

|||

Standard Type (1.8°) |

Encoder |

0.85 ~ 1.5 A |

4 |

28 ~ 52 oz-in |

0.2 ~ 0.37 N·m |

|

Standard Type (1.8°) |

Encoder |

0.28 ~ 2.3 A |

4 |

14.2 ~ 140 oz-in |

0.1 ~ 0.99 N·m |

|

High-Resolution (0.9°) |

0.67 ~ 1.5 A |

42 ~ 116 oz-in |

0.3 ~ 0.82 N·m |

|||

Geared Type |

Encoder |

1.5 or 2.3 A |

28 ~ 2,544 oz-in |

0.2 ~ 18 N·m |

||

Standard Type |

Encoder |

2.3 A |

4

|

14.2 oz-in |

0.1 N·m |

|

Geared Type |

2.3 A | 255 ~ 339 oz-in |

1.8 ~ 2.4 N·m |

|||

|

|

Standard Type (1.8°) |

Encoder |

0.71 ~ 4.2 A |

4 |

85 ~ 440 oz-in |

0.74 ~ 3.1 N·m |

High-Resolution (0.9°) |

1.4 ~ 2.8 A |

99 ~ 320 oz-in |

0.7 ~ 2.3 N·m |

|||

Geared Type |

Encoder |

1.4 ~ 4.2 A |

140.8 ~ 6,224 oz-in |

1 ~ 44 N·m |

||

Standard Type |

Encoder |

1.5 A |

4 |

25.5 oz-in |

0.18 N·m |

|

Geared Type |

480 ~ 704 oz-in |

3.5 ~ 5 N·m |

||||

Standard Type (1.8°) |

- | 4.5 ~ 6.3 A |

4 |

467 ~ 1345 oz-in | 3.3 ~ 9.5 N·m | |

Geared Type |

- |

2,096 ~ 16,992 oz-in |

14.85 ~ 120 N·m |

|||

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-468-3982