DR/DRS2 Series Compact Electric Cylinders

DR/DRS2 Series Compact Electric Cylinders with Absolute Encoder Stepper Motors

The DR/DRS2 Series compact linear cylinder uses the αSTEP AZ Series stepper motor and driver. The actuator is equipped with the Mechanical Absolute Encoder Stepper Motor. The Absolute Encoder is a mechanical multi-turn Absolute Sensor, so an external sensor is not required. This helps to save space and reduce wiring, as well as more compact and lightweight design of the equipment. Table Type or Rod Typeavailable.

- AZ Series Absolute Encoder Stepper Motor

- Table Type or Rod Type

- 24/48 VDC Input

- AZ Series Connection Cables and DC Input Driver required (sold separately)*

Mechanical Absolute Encoder

Compact Electric Cylinders

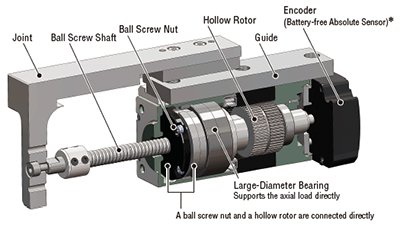

Reliable Design and Structure

A hollow rotor and a ball screw nut are joined. Since no connecting parts are necessary, there is less backlash than when coupling rigidity, etc. combines other parts. Therefore, highly accurate positioning can be achieved.

High Positioning Accuracy

The ball screw nut is linked with the hollow rotor. Through the coupling rigidity and other aspects of parts combination, the impact of backlash has been minimized achieving high-precision positioning.

Ground Ball Screw

Ideal for applications where high positioning accuracy and low vibration are required, such as optical devices and semiconductor systems that use fine-feed pitches. The DR/DRS ground ball screw type achieves high reliability by maximizing the performance of a 5-phase stepper motor.

Rolled Ball Screw

Ideal for general positioning applications where reliability and ease of use are given priority. It combines the superior thrust and resolution of the ground ball screw type with greater ease of use.

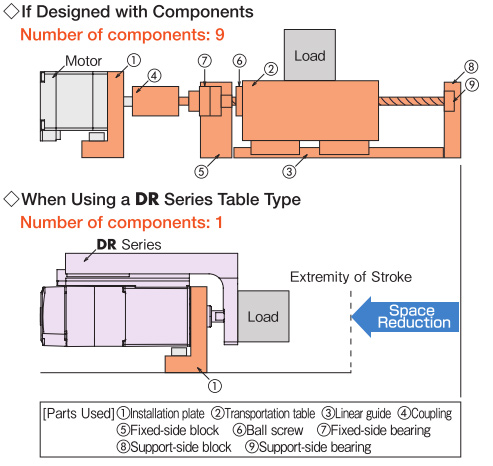

Compact Body Houses Entire Linear Motion Mechanism

Since customers do not need to provide parts, the time needed for installing, designing, and selecting parts can be reduced. The number of man-hours required for assembly and adjusting the installation accuracy can be reduced, contributing to higher productivity.

Installation Time Reduced

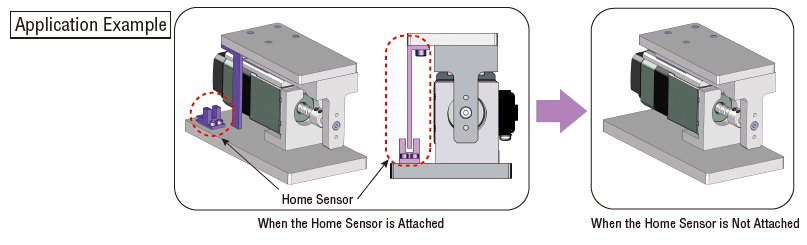

Space Saving and Less Wiring with the Absolute Sensor

In addition to the compact and lightweight body, the motors with absolute sensors do not require a home sensor. This saves space and wiring, and lets you avoid routine maintenance or trouble caused by using a home sensor.

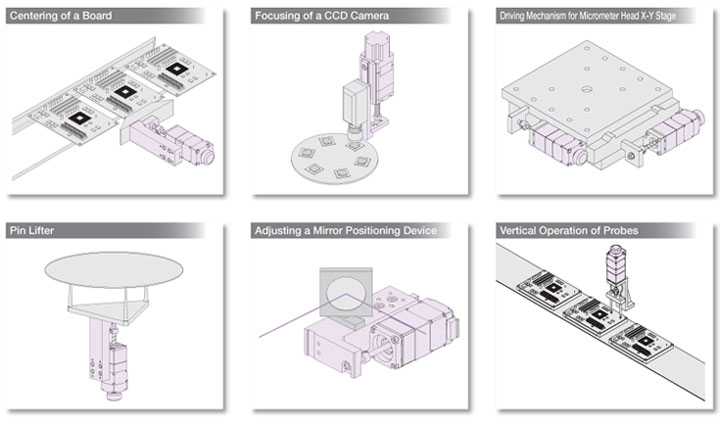

Application Examples

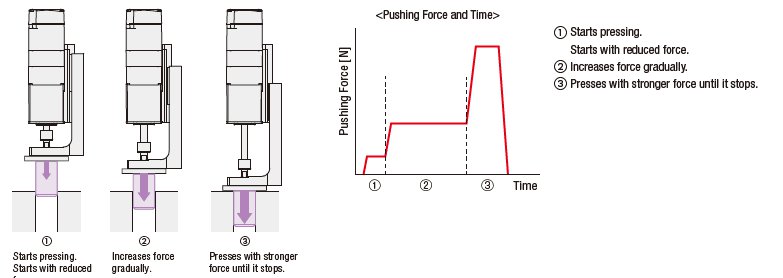

Efficient Push-Motion Operation

Flexible Pushing Force and Timing

The αSTEP DR/DRS2 Series can easily perform a push-motion operation after a positioning operation. Also, the pushing force and timing are adjustable.

- You can set the pushing force and push timing to an operation data No., and then select the data No. to change the settings.

- There are different ways to change the pressing phases, such as dropping the force so that the position does not shift, slowly increasing

the force, or rapidly increasing the force.

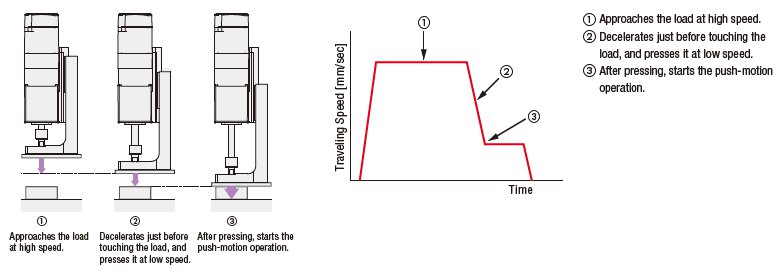

Pressing at Low Speed

The motor can approach the load at high speed. The motor decelerates just before hitting the surface at low speed.

- Since the pressing impact is minimal, a mechanism for shock absorption is not required.

- The motor can approach at high speed just before reaching the surface, thus reducing the takt time.

Push-Motion Operation with Pulse Input Type

When T-MODE input is set, push-motion operation is possible, without the overload alarm for the pulse input type being generated.

This is useful for push-motion operation while using pulse signal control.

AZ Series Absolute Sensor Stepper Motor

Newly Developed Absolute Sensor

Oriental Motor has developed a compact, low-cost, battery-free mechanical type absolute sensor (patented). This can help improve productivity and reduce costs.

Mechanical-Type Sensor

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears.

Multi-turn absolute sensor

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the reference home position.

Home Setting Method

The home position can be easily set by pressing a switch on the driver's surface, which is saved by the Absolute Sensor. In addition, home setting is possible with the data setting software (MEXE02) or by using an external input signal.

Battery-free

No battery is required thanks to a mechanical-type sensor. Positioning information is managed mechanically by the absolute sensor.

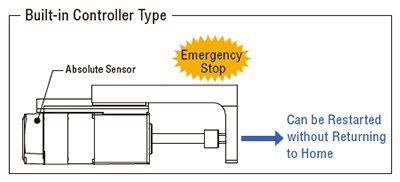

Holding Positioning Information

Even if the power shuts down during a positioning operation or

the cable between the actuator and the driver is disconnected,

the positioning information is retained. With the built-in controller

type, you can restart the positioning operation, without performing

return-to-home after an emergency stop on the production line or

a blackout.

Reduced Maintenance

Because there is no battery that needs replacing, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control cabinet.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Absolute Sensor does not require a battery, so there is no limit as to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

No External Sensors Required

With the use of the absolute system, external sensors such as the home sensor and the limit sensor are not needed.

High Speed Return-to-Home

Because return-to-home is possible without using an external sensor, return-to-home can be performed at high speed without taking the specifications for sensor sensitivity into account, allowing for a shortened machine cycle.

Reduced Cost

Sensor costs and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified, and the degree of freedom for equipment design is increased.

Not Affected by External Sensor Malfunctions

There is no need for concern about sensor malfunctions, sensor failures, or sensor wire disconnections.

Improved Return-to-Home Accuracy

Home position accuracy is increased because the return-to-home operation is performed regardless of any variations in home sensor sensitivity.

*If no limit sensor is installed, movements that exceed the limit values can be avoided through the use of the limits in the driver software.

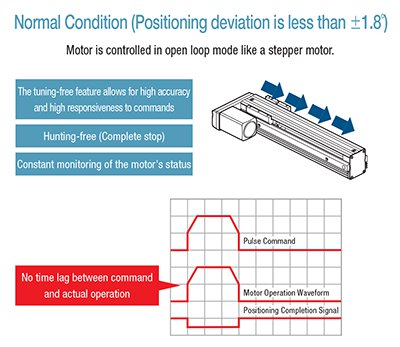

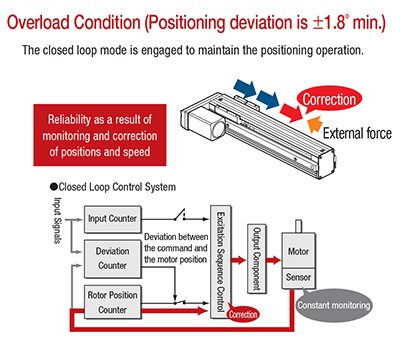

αSTEP Control System

Hybrid Control System

The hybrid control system constantly monitors the motors position allowing for the benefits of performance from "open loop" control while providing the assurance of "closed loop " performance.

Table Type

- 20 mm (0.79 in.)

- 28 mm (1.10 in.)

- 42 mm (1.65 in.)

Compact electric cylinders with built-in table reduces the need for an external anti-spin mechanism further reducing parts required for designing your applications.

High Transportable Mass and High Speed are Achieved

Maximum Transportable Mass

- Horizontal direction: 10 kg [Lead 2 mm], 5 kg [Lead 8 mm]

- Vertical direction: 10 kg [Lead 2 mm], 5 kg [Lead 8 mm]

Maximum Speed

- 50 mm/sec [Lead 2 mm], 200 mm/s [Lead 8 mm]

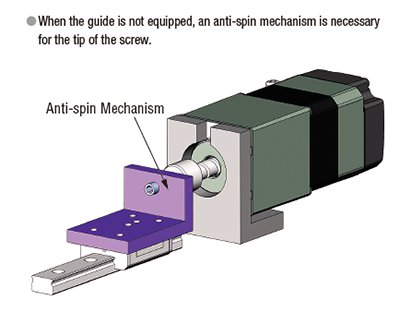

Rod Type

- 20 mm (0.79 in)

- 28 mm (1.10 in.)

- 42 mm (1.65 in.)

- 60 mm (2.36 in.)

The rod type electric cylinders, require the use of an Anti-spin Mechanism

Ball Screw Cover

- 20 mm (0.79 in.)

- 28 mm (1.10 in.)

Compact electric cylinders with a simple ball screw cover are available.

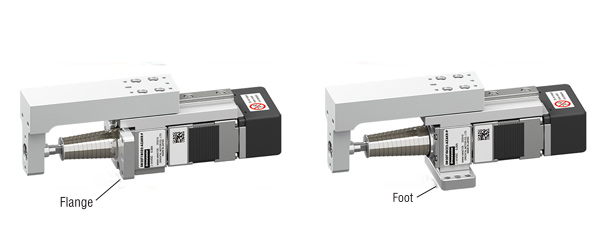

Installation Plate

- 20 mm (0.79 in.)

- 28 mm (1.10 in.)

Types with an installation plate are available. One type uses a flange and is installed from the back face, and the other type uses a foot for installation from the top face.

Electromagnetic Brake

- 42 mm (1.65 in.)

- 60 mm (2.36 in.)

The load position can be held when the power is cut off. Since the work will not fall in case of power failure or disconnection, you can safely use equipment in which the work moves vertically.

Linear Actuator Lineup

Actuator Type |

Frame Size |

Power Supply |

Available Options |

Thrust Force |

Stroke |

Table Type |

24/48 VDC |

- |

15 N |

25 mm |

|

- |

20 N 40 N |

30 mm |

|||

| Electromagnetic Brake | 50 N 200 N |

40 mm | |||

Rod Type |

24/48 VDC |

- |

15 N |

25 mm |

|

- |

20 N 40 N |

30 mm |

|||

| Electromagnetic Brake | 50 N 200 N |

40 mm | |||

| Electromagnetic Brake | 500 N | 50 mm |

AZ Series DC Input Drivers

The αSTEP DC Input Drivers offer 24/48 VDC input voltage, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. The αSTEP AZD-K (DC Input) can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- 24/48 VDC

- For use with αSTEP AZ Series Motors (DC Input)

![]()

Multi-Axis Controller / Driver (EtherCAT)

A multi-axis controller that supports EtherCAT communication. Compatible with the CiA402 drive profile. It can be connected to the AZ Series DC input motors and electric actuators.

2-axis, 3-axis and 4-axis driver connections are available.

- 24/48VDC

- Multi-Axis Motor Connection Cables required*

![]()

Cables for Single-Axis Drivers

These cables are used to connect or extend the distance between the motor and single-axis driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

*Multi-Axis Controller / Driver requires different cables

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

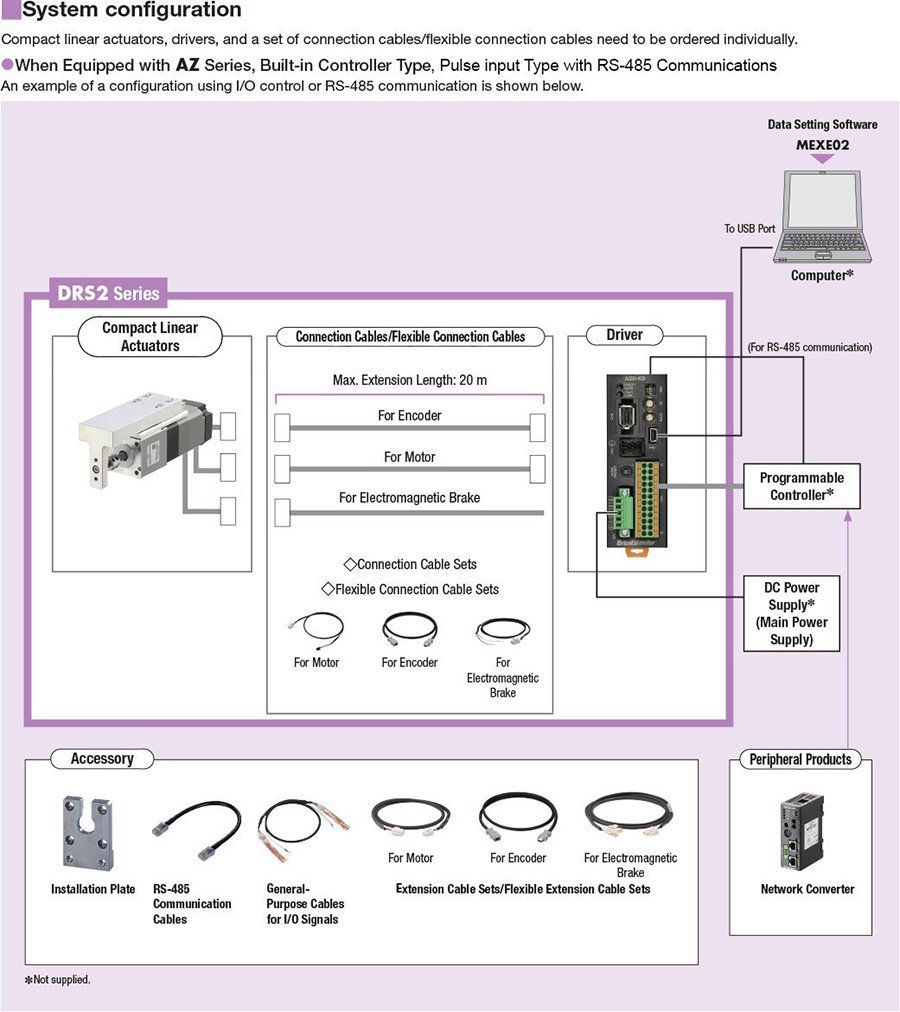

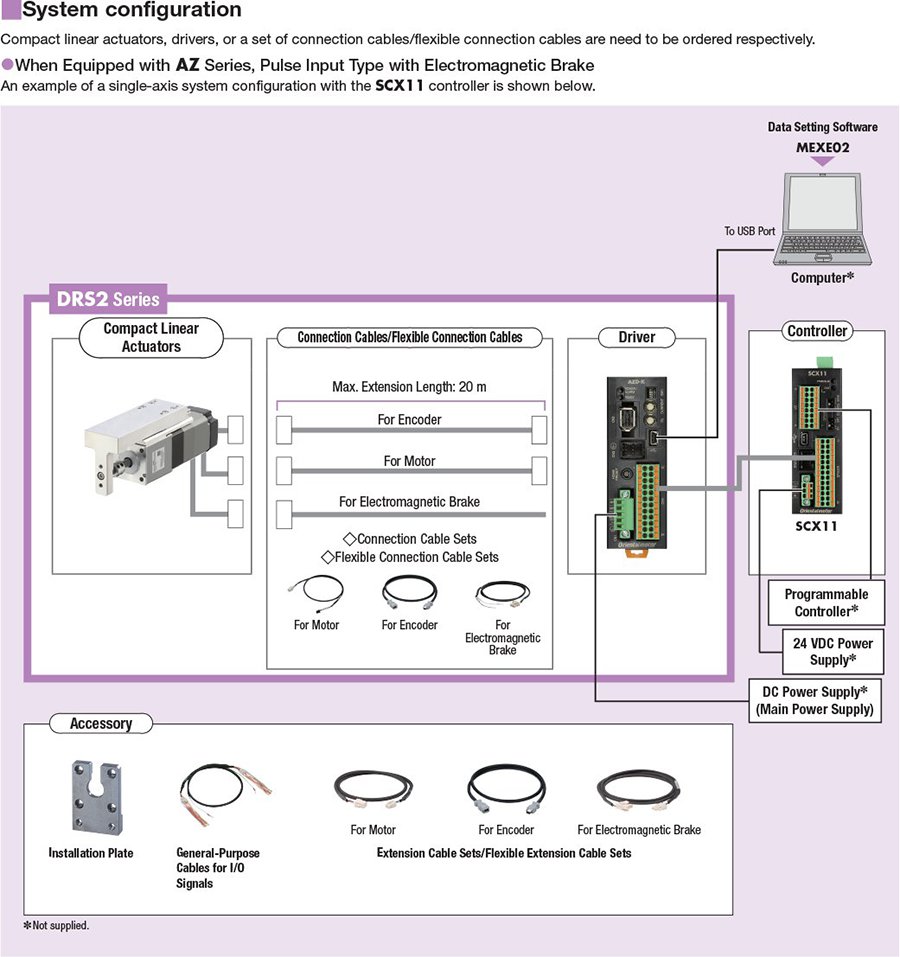

System Configuration

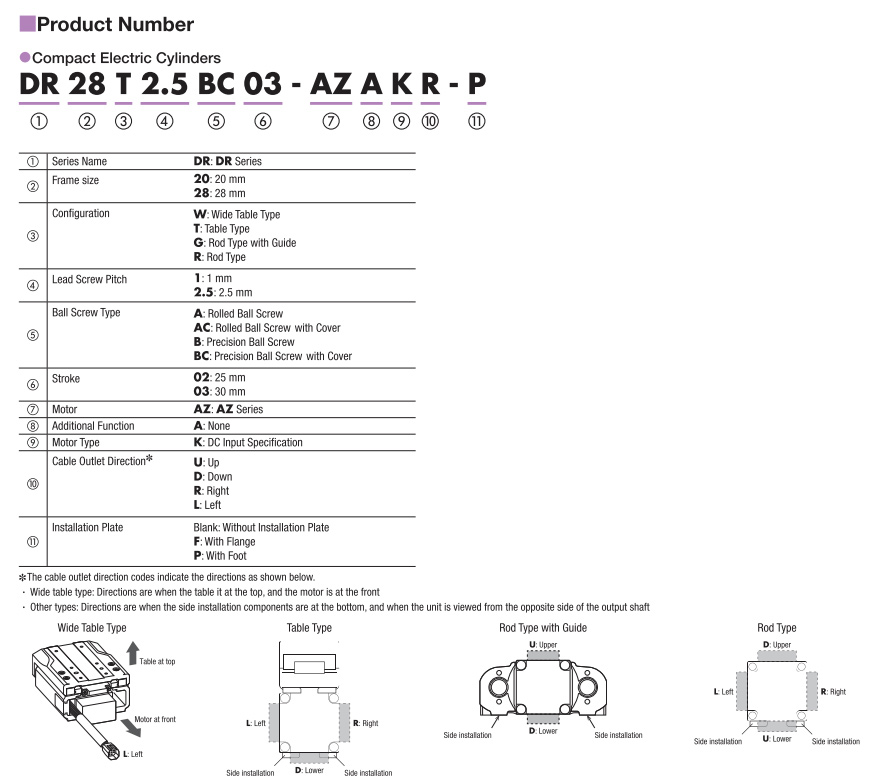

Product Number Code

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.

Videos