DGII Series Closed Loop Hollow Rotary Actuators

DGII Series Closed Loop AZ Series Absolute Encoder Hollow Rotary Actuators

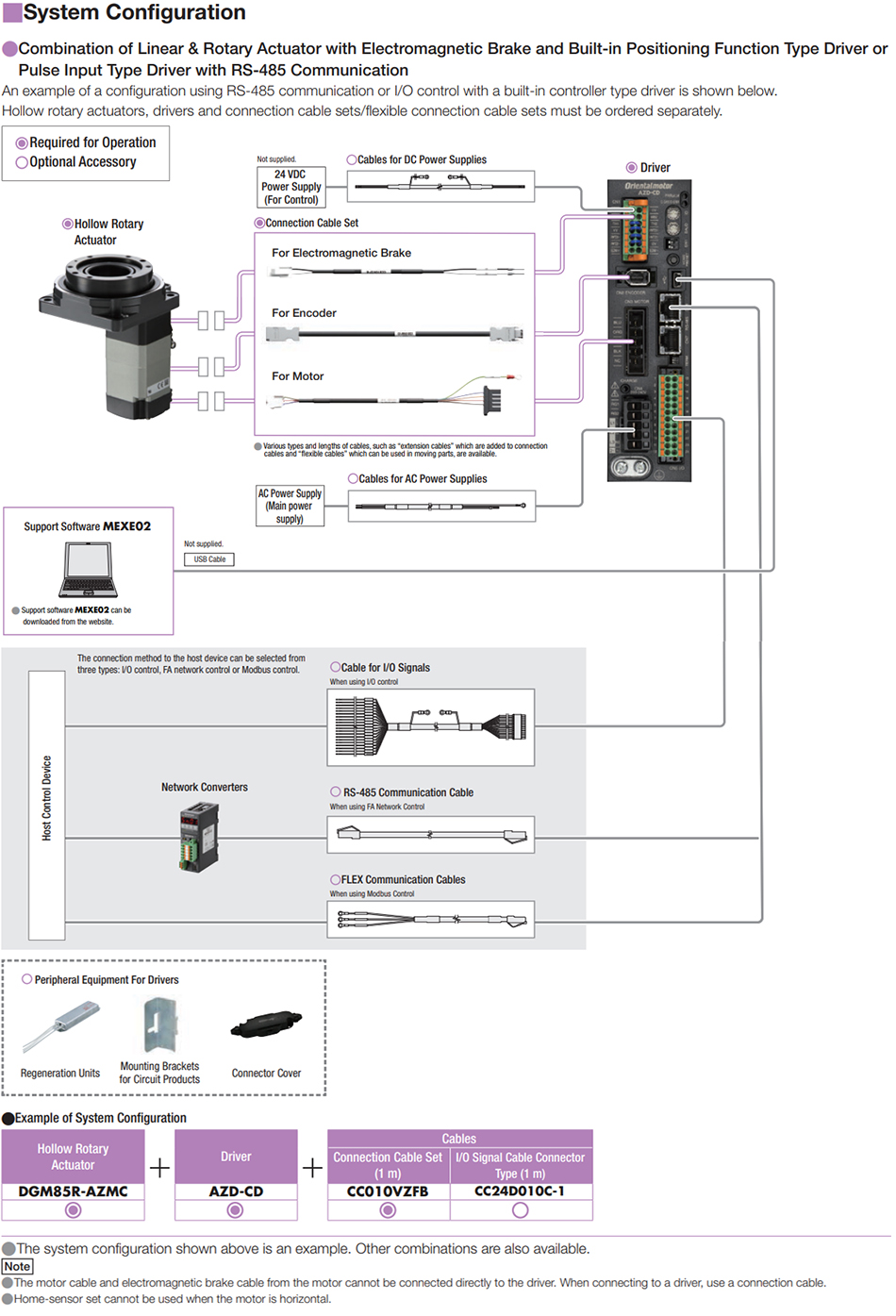

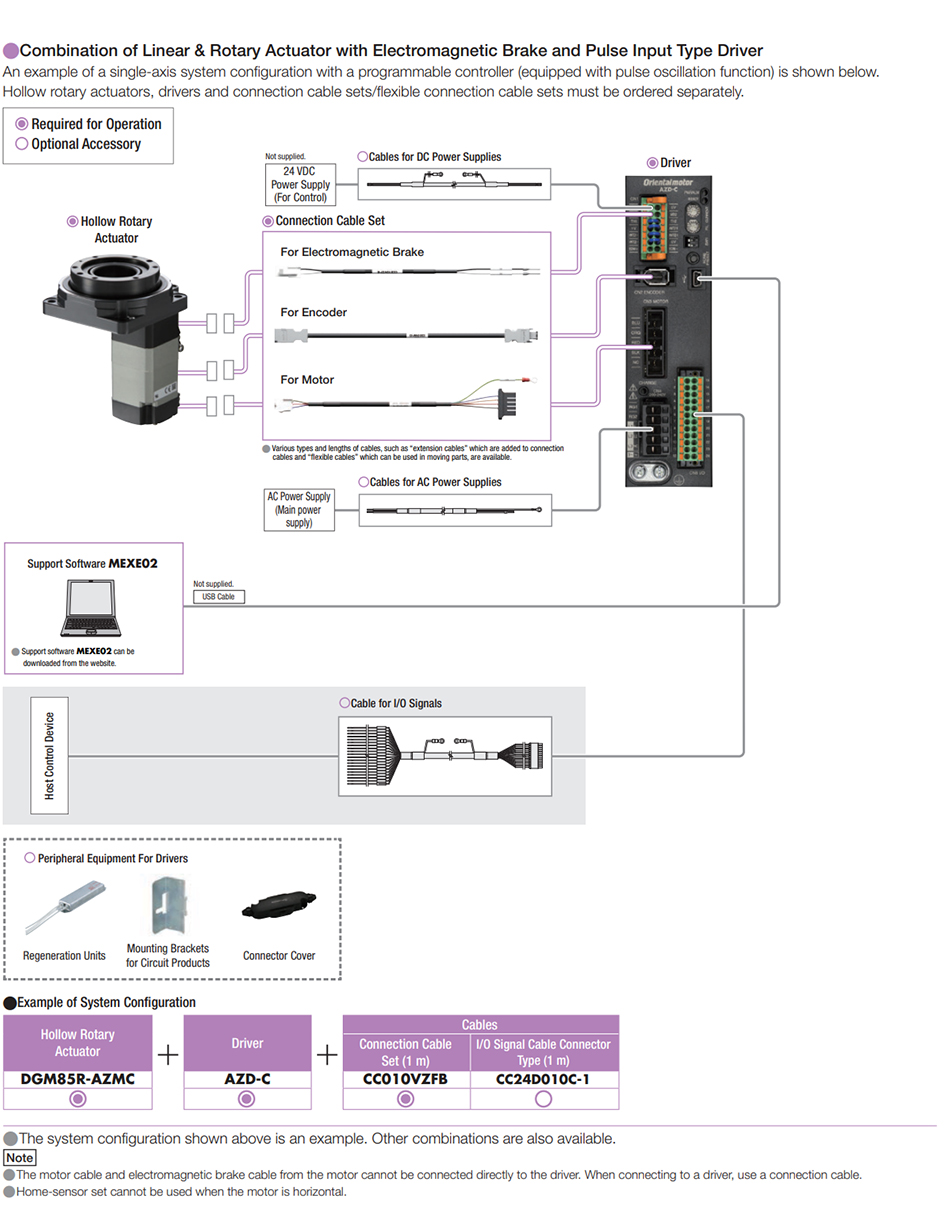

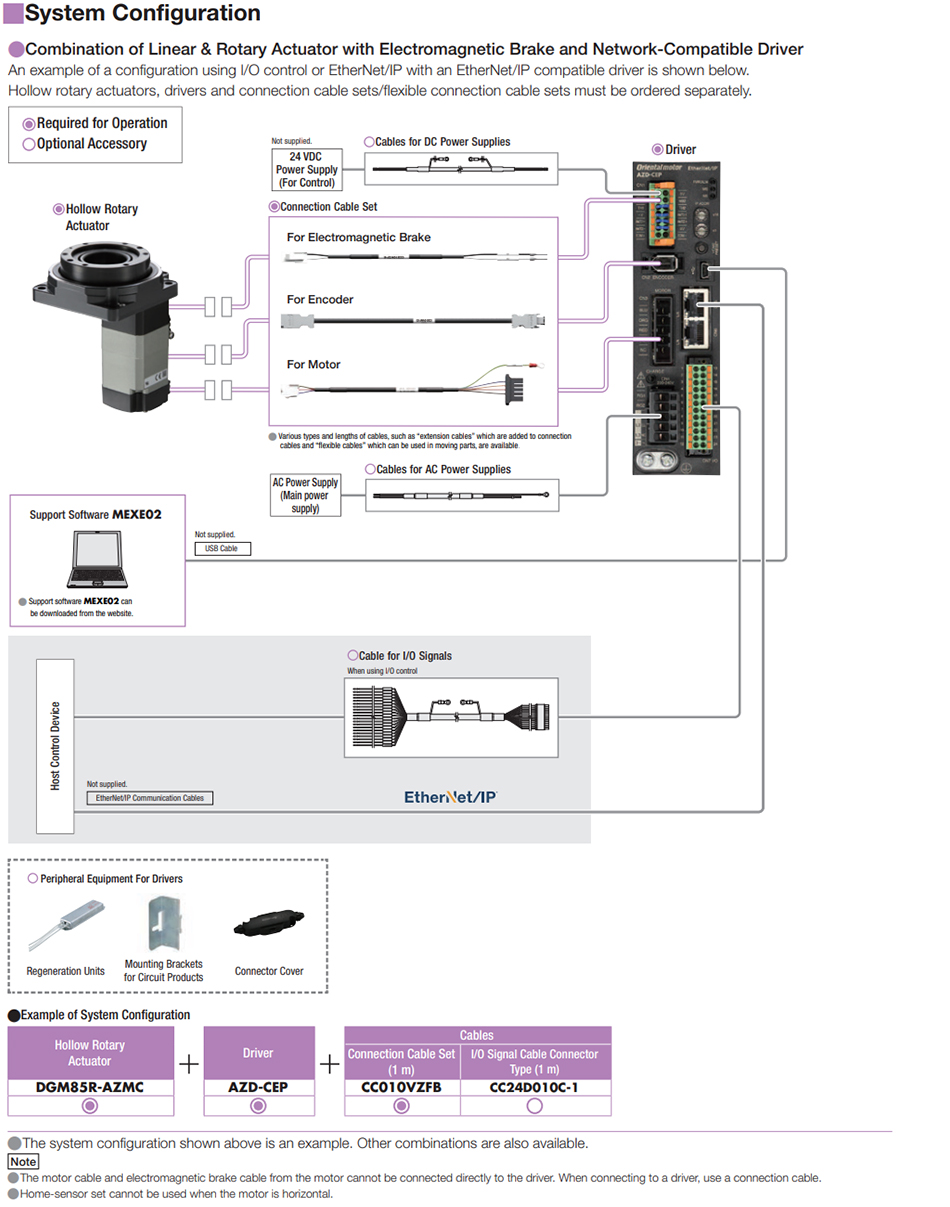

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an αSTEP absolute encoder AZ series closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

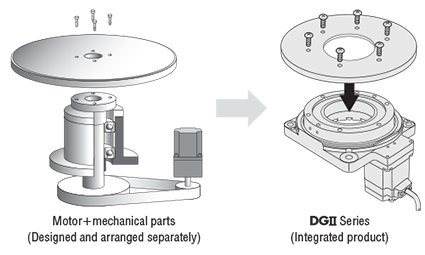

- Integrated actuator and stepper motor makes design easier

- Vertical or Horizontal Mount Motor Types

- Easy Home Setting and Return-to-Home without need for sensors

- Large-diameter hollow output table

- Stepper motor provides excellent performance

- Agile responsiveness

- Stability at low speeds

- Tuning-free

- Requires AZ Series Driver (sold separately)

- Use Ethernet Type mini Driver with 3rd party robots:

- Universal Robot e-Series (UR+ Certified)

- FANUC CRX Series Robots (Plug-in Compatible)

Mechanical Absolute Encoder

Contributes to Easier Equipment Design

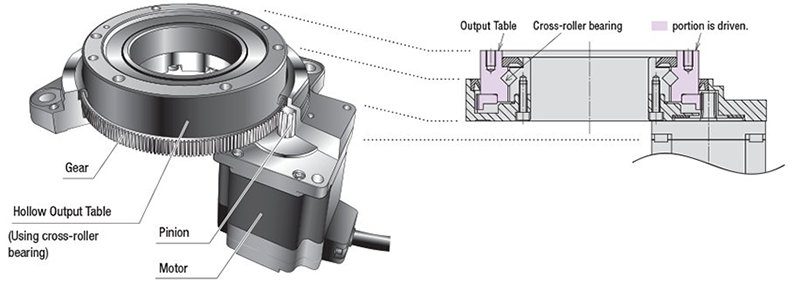

The gear-reduction mechanism employs precision gears along with a proprietary adjustment mechanism that eliminates backlash. The repetitive positioning accuracy from a single direction is ±15 sec., while lost motion in a positioning operation from two directions is 2 arc minutes. These characteristics make the DGII series the ideal choice for applications in which accurate positioning is a must.

*DGM60 features Deep-Groove Ball Bearings

Direct Coupling for Higher Reliability

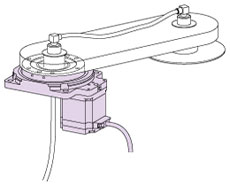

Equipment tables and arms can be installed directly on the output table. This saves you the hassle and cost of designing an installation mechanism, arranging necessary parts, adjusting the belt tension, etc. when mechanical parts such as belt and pulley are used for installation.

High-precision Positioning

High-precision positioning is achieved by a combination of motor and rotary table mechanism.

Motor Direction |

Backlash |

Repetitive Positioning Accuracy |

Vertical |

non-backlash |

±15 arcsec (±0.004˚) |

Horizontal |

3 - 10 arcmin |

±15 arcsec (±0.004˚) |

Horizontal (Pedestal) |

6 arcmin |

±30 arcsec (±0.008˚) |

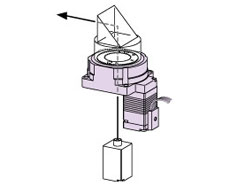

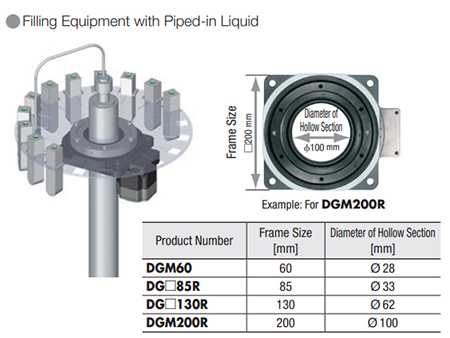

Large-Diameter, Hollow Output Table Makes Simple Wiring and Piping Possible

The large diameter hollow hole (through-hole) helps reduce the complexity of wiring and piping, thus simplifying your equipment design.

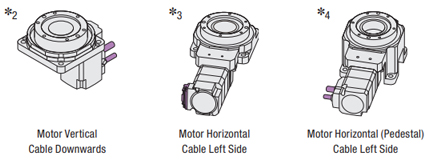

Select the cable pull-out direction to suit the application (only with AZ Series mounting)

The direction of the motor cable pull-out can be selected to suit the application.*1

Motor Direction |

Cable pull-out direction/connector direction | |||

Upward |

Downward |

Right Side |

Left Side | |

| Vertical | x | ○*2 | ○ | ○ |

| Horizontal | ○ | ○ | ○ | ○*3 |

Horizontal (Pedestal) |

x |

x |

○ |

○*4 |

*1 May not be available depending on mounting angle dimensions. Please check the outline drawing.

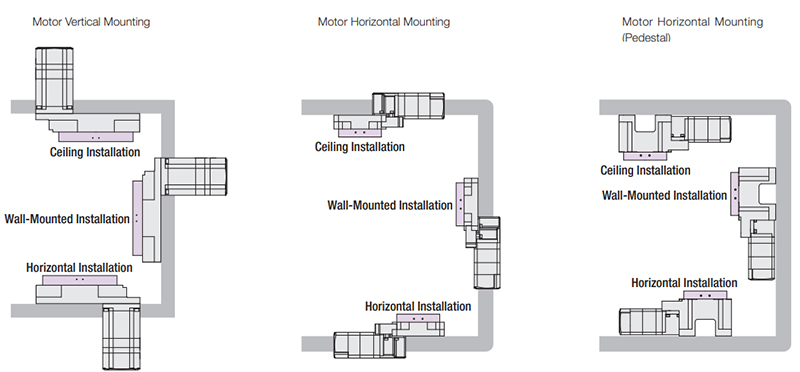

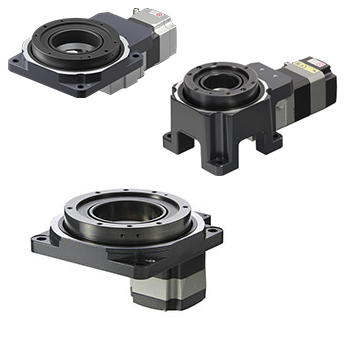

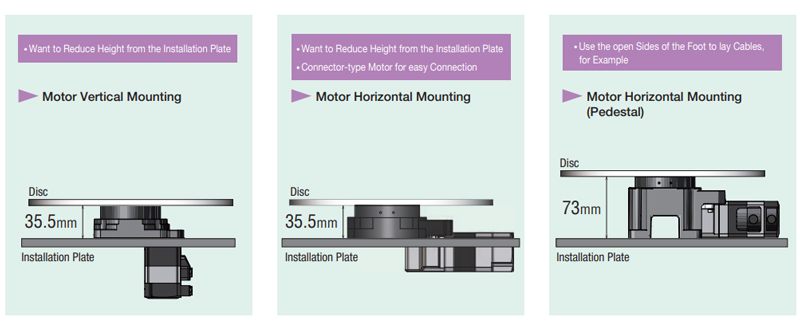

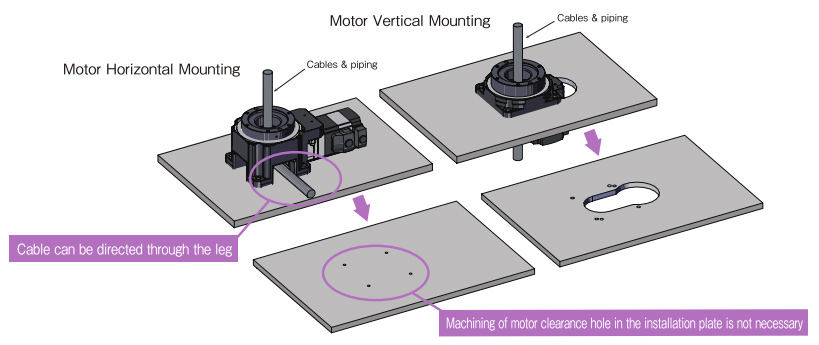

Specific Use for Specific Space

In addition to the conventional type in which the rotary table shaft and the motor shaft were arranged in parallel (motor vertical mounting), the product lineup also includes types in which the rotary table shaft and the motor shaft are perpendicular (motor horizontal mounting).

Select the type that best suits the installation space for the equipment.

(Example: For standard type with frame size of 85 mm)

Advantages of Motor Horizontal Mounting

- Machining of motor clearance hole is not necessary, thereby simplifying the installation plate.

- Improved installability due to elimination of installation pedestal.

- Cabling and piping can be routed between legs underneath the table.

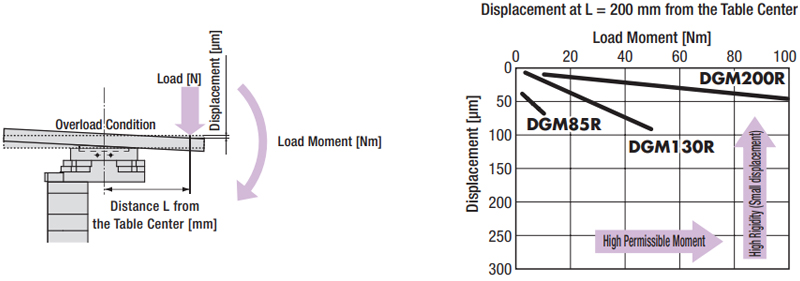

Relationship Between Displacement and the Load Moment Positioned 200 mm from the Table Center

The received permissible moment increases as the product number increases, and the displacement caused by the load moment decreases.

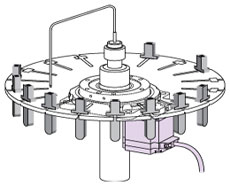

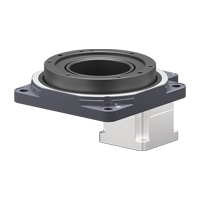

High Load and High Rigidity

A cross-roller bearing is used for the bearing on the hollow output table, providing high load and high rigidity. (Except for DGM60)

- Max. Permissible Axial Load: 4000 N

- Max. Permissible Moment: 100 Nm

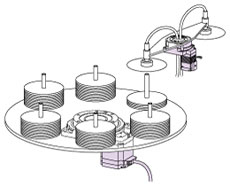

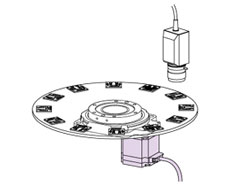

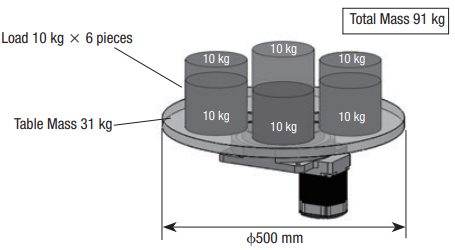

High Load

Example: Driving with 6 loads on a table

Load Mass: 91 kg

Table 31 kg (Diameter 500 mm, thickness 20 mm, iron)

Load 10 kg × 6 pieces

Can be Used for Rotation Applications Around a Robot’s Peripheral Axis

Universal Robot Certified

- Rotary actuators that can be linked to universal robots

- Easily set with URCap

FANUC Plug-in Compatible

- Can be linked to FANUC's CRX Series cobots

- Easy configuration through Tablet TP

Hybrid Control System

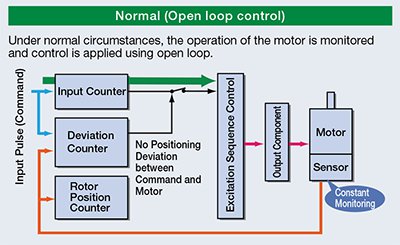

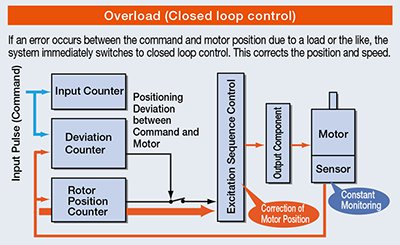

αSTEP products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

The position of the motor is always monitored, and then the driver automatically switches between 2 types of control depending on the situation.

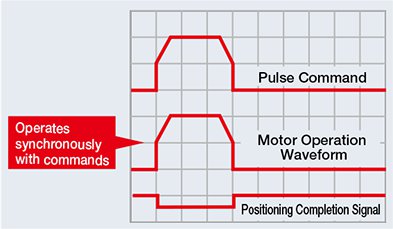

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.

Because of Absolute System, Easy Home Setting and Return-to-Home is Possible

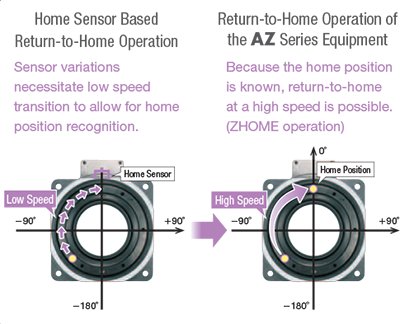

No Return-to-Home Sensor Required

Because it is an absolute system, no home sensor is necessary.

Reduced Costs

Sensor and wiring costs can be reduced, leading to overall lower system costs.

Not Affected by Sensor Malfunctions

There is no concern about sensor malfunction, sensor failure, or sensor wire disconnection.

Improved Return-to-Home Accuracy

Return-to-home is carried out without any concern over variation in home sensor detection, which can improve home accuracy.

*If no limit sensor is installed, driver software limits are used to prevent operation when a limit is exceeded.

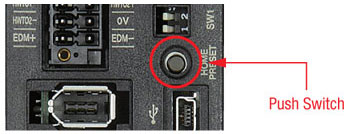

Easy Home Setting

By pressing the switch on the driver surface, home position can be set simply, and the home position can be saved with the sensor. Furthermore, it is possible to set the home position using the data setting software (MEXE02) or the external input signal.

High-Speed Return-to-Home

Since return-to-home is possible without the use of a home sensor, return-to-home is carried out at high speed without any concern over sensor sensitivity, which can shorten the machine cycle.

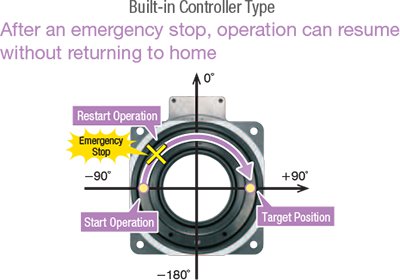

Return-to-Home Not Required

The position information s retained even if the power shuts off during positioning. Furthermore, if the built-in controller type is being used, positioning is restarted without return-to-home when the power is restored after a power outage or an emergency top on the production line.

The Mechanical Sensor does not Need a Battery

Battery-Free

The sensor is mechanical, thus it doesn't require a battery. Since position information is mechanically managed by the absolute sensor, positioning information can be retained even if there is a power outage or the cable between the motor and driver is disconnected.

Reduced Maintenance

Because there is no battery that needs replacement, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Long Distance Shipping

Ordinary batteries self-discharge, thus caution is required for long-term transportation, such as overseas shipping. The motor sensor is battery-free, thus there are no restrictions on the retention of positioning information. This also means that there are no concerns about shipping regulations for batteries when exporting.

Position Retention Even if the Cable Between the Motor and Driver is Disconnected

Positioning Information is retained in the motor sensor.

Useful Functions Thanks to the Built-in AZ Series

Convenient Operation & Setting

By using the AZ Series functions, the hollow rotary actuator's output table coordinates are managed and the following operations become possible.

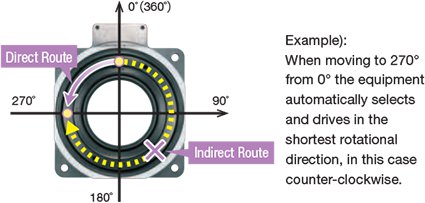

Short-Cut Operation Reduces Takt Time

This is an operation method that drives the equipment in the rotation direction, providing the shortest distance to the target position that has been set. It can reduce the amount of takt time for the equipment.

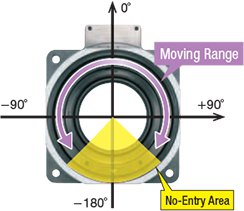

Easy Control by Setting No-Entrance Areas

If there are dangerous or damaging items on the equipment, it is possible to set an area into which the output table cannot be moved.

Reduced Equipment Setup Time

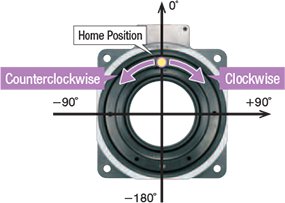

The parameters necessary to operate the hollow rotary actuator are set at the time of shipment, which contributes to reduce equipment setup time.

- Home Position

- Resolution Setting (0.01°/step)

- Output Table Rotation Direction Setting

- Round Setting ±180°

All of the initial settings can be changed.

Rotary Actuator Lineup

Power Input |

Type |

Frame Size |

Options |

Permissible |

Permissible Speed |

Permissible Moment Load |

||

AC Input |

Vertical Motor Mount |

Electromagnetic Brake |

4.5 N·m |

39.8 lb-in |

200 r/min |

10 N·m |

88 lb-in |

|

12 N·m |

106 lb-in |

200 r/min |

50 N·m |

440 lb-in |

||||

50 N·m |

440 lb-in |

110 r/min |

100 N·m |

880 lb-in |

||||

Horizontal Motor Mount (Pedestal) |

Electromagnetic Brake |

3 ~ 9 N·m |

26 ~ 79 lb-in |

100 ~ 300 r/min |

10 N·m |

88 lb-in |

||

12 ~ 24 N·m |

106 ~ 210 lb-in |

100 ~ 200 r/min |

50 N·m |

440 lb-in |

||||

Horizontal Motor Mount |

Electromagnetic Brake |

9 N·m |

79 lb-in |

100 r/min |

10 N·m |

88 lb-in |

||

24 N·m |

210 lb-in |

100 r/min |

50 N·m |

440 lb-in |

||||

DC Input |

Vertical Motor Mount |

- |

0.9 N·m | 7.9 lb-in | 200 ~ 333 r/min | 7 N·m | 17.7 lb-in | |

Electromagnetic Brake |

4.5 N·m |

39.8 lb-in |

200 r/min |

10 N·m |

88 lb-in |

|||

12 N·m |

106 lb-in |

200 r/min |

50 N·m |

440 lb-in |

||||

Horizontal Motor Mount (Pedestal) |

- |

3 ~ 9 N·m |

26 ~ 79 lb-in |

100 ~ 300 r/min |

10 N·m |

88 lb-in |

||

12 ~ 24 N·m |

106 ~ 210 lb-in |

100 ~ 200 r/min |

50 N·m |

440 lb-in |

||||

Horizontal Motor Mount |

-

|

1.3 N·m |

11.5 lb-in |

200 r/min |

7 N·m | 62 lb-in | ||

9 N·m |

79 lb-in |

100 r/min |

10 N·m |

88 lb-in |

||||

24 N·m |

210 lb-in |

100 r/min |

50 N·m |

440 lb-in |

||||

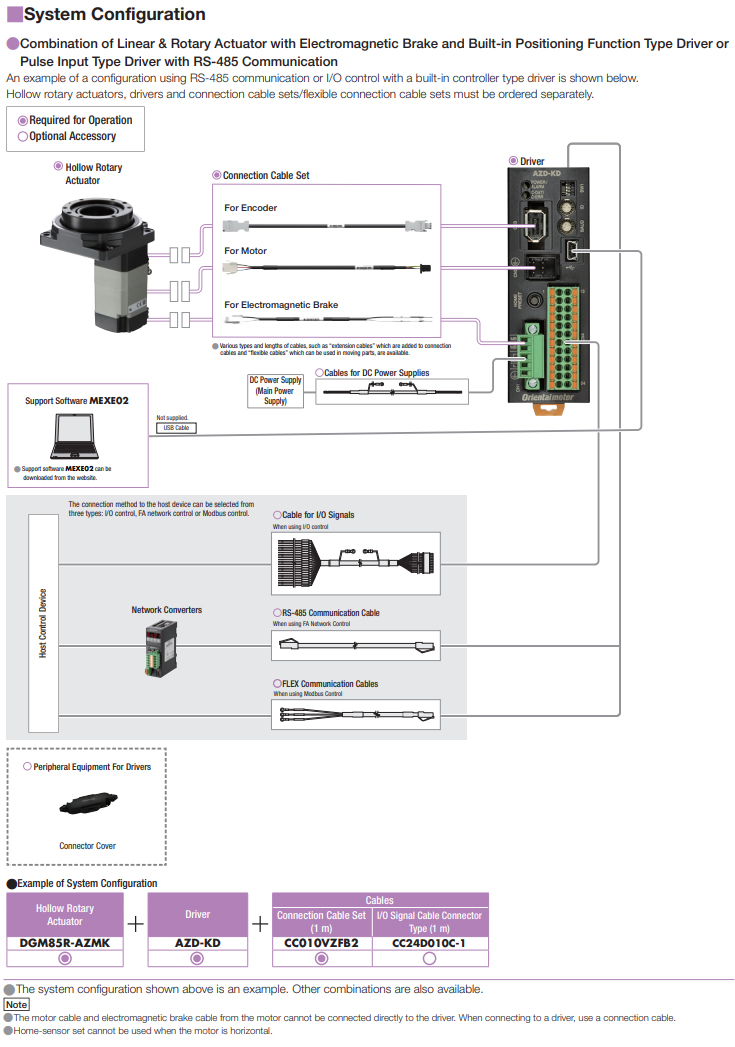

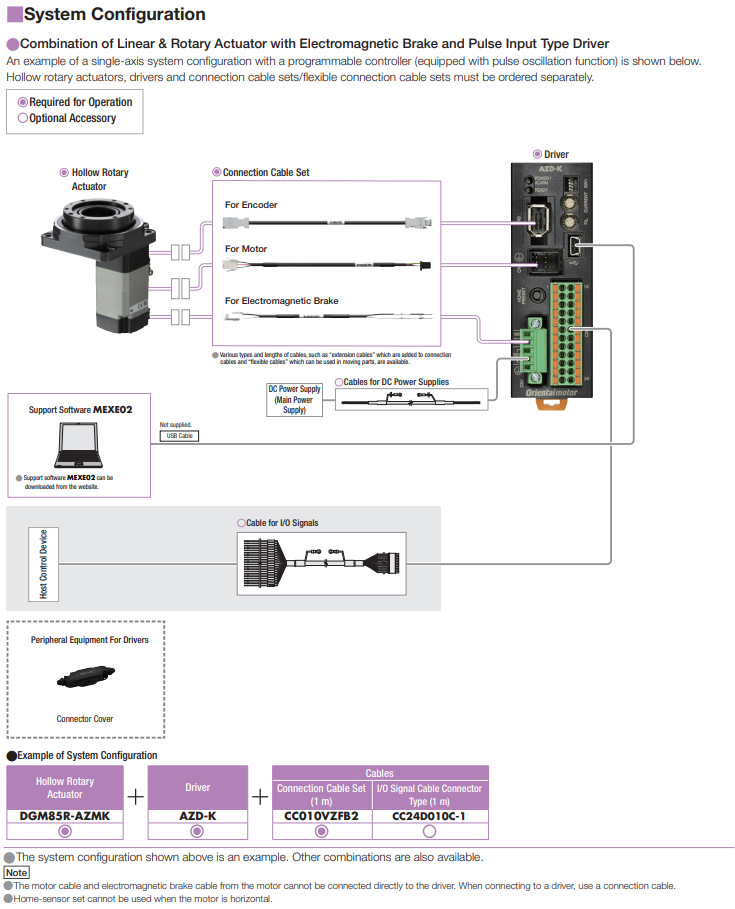

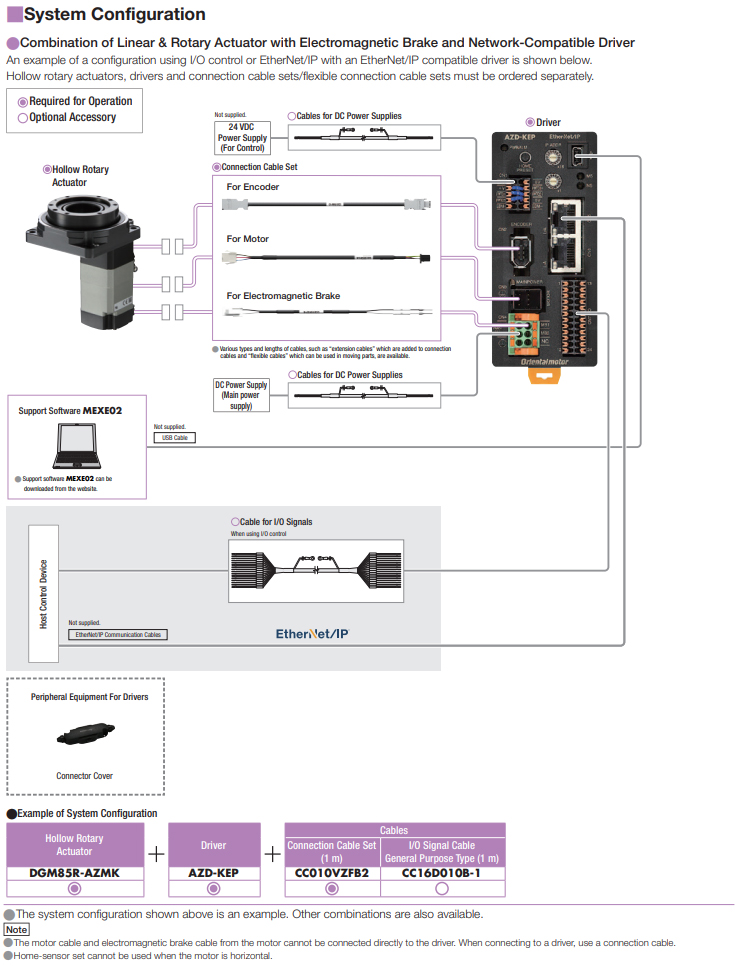

AZ Series AC Input Drivers

The αSTEP AZD (AC Input) Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Emergency Torque Off Function

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with αSTEP AZ Series Motors (AC Input)

![]()

AZ Series DC Input Drivers

The αSTEP DC Input Drivers offer 24/48 VDC input voltage, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. The αSTEP AZD-K (DC Input) can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- 24/48 VDC

- For use with αSTEP AZ Series Motors (DC Input)

![]()

Multi-Axis Controller / Driver (EtherCAT)

A multi-axis controller that supports EtherCAT communication.Compatible with the CiA402 drive profile. It can be connected to the AZ Series DC input motors and electric actuators.

2-axis, 3-axis and 4-axis driver connections are available.

- 24/48VDC

![]()

Cable Type Motor Connection Cables

These cables are used to connect or extend the distance between the motor and driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Connector Type Motor Connection Cables

These cables are used to connect a “Connector Type” motor and a driver.

Note: For the DC Input type, mini Drivers and Multi-Axis Drivers use different connection cables. Please contact technical support for details.

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.

Application Examples

Applications subject to changing load inertia |

Applications where a moment load is applied |

Optical applications using the hollow hole |

|

|

|

High accuracy positioning applications |

High accuracy positioning applications using the hollow hole |

Air absorption applications using the hollow hole |

|

|

|

Installation Direction Examples

The DG II Series can be installed horizontally and be ceiling mounted or wall mounted.

Note

A small amount of grease will occasionally seep out of the hollow rotary actuator. If a grease leak would cause a contamination issue near the machine, either perform routine inspections, or install protective equipment such as an oil sump.