OVR Series SCARA Robots

OVR Series SCARA Robots

![]()

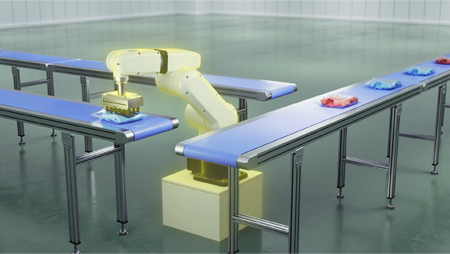

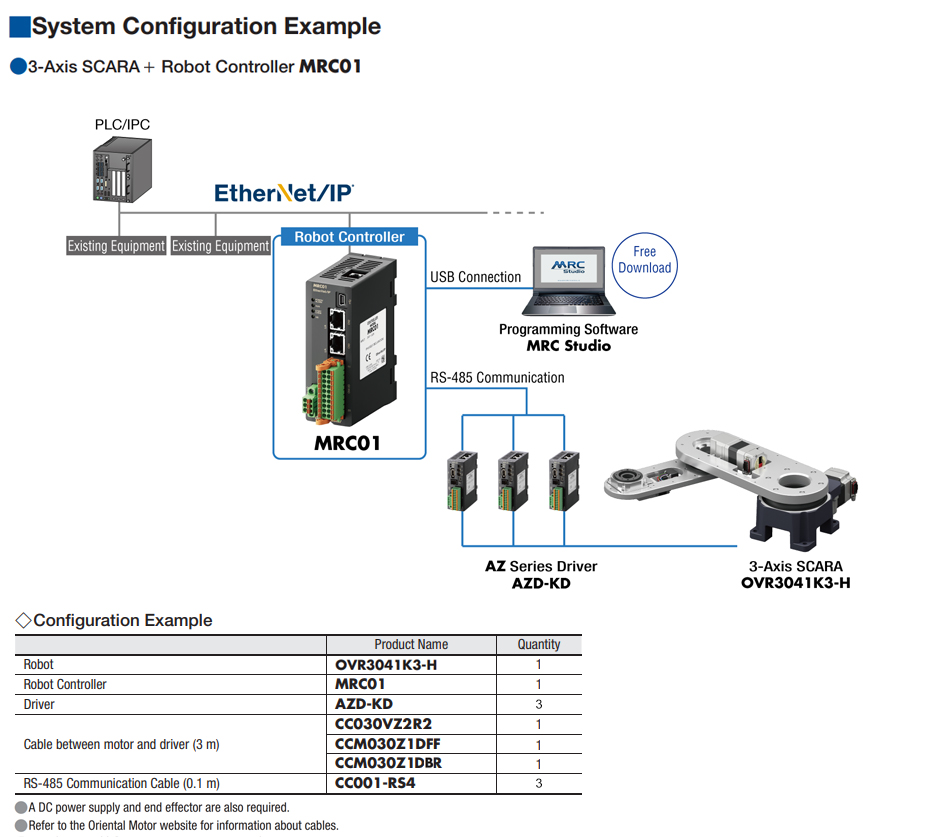

The OVR Series SCARA 3-axis small horizontal transport robot features a simple mechanism that can be easily controlled and constructed cost-effectively. SCARA (Selective Compliance Assembly Robot Arm) uses a parallel Z-axis combined with compliant X-Y axes to provide accurate movement in confined areas. The pedestal mount creates a small footprint and the SCARA robot is typically faster than a Cartesian Robot. Control with the MRCU Integrated Robot Controller & Drivers.

- Approach narrow spaces (compared to general SCARA robots)

- Lightweight and flat with chassis mass of 7.6 ~ 8.9 kg and a height of 137 ~ 205 mm

- Transportable mass 3 ~ 10 kg

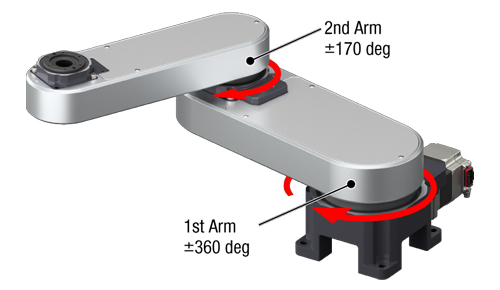

- 2 moving range types: ±170 deg or ±360 deg

- Simple dust-resistant structure available

- The use of mounting brackets expands the operating range in the vertical direction

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) uses a parallel Z-axis combined with "compliant" X-Y axes to provide accurate movement in confined areas. The pedestal mount creates a small footprint and the SCARA robot is typically faster than a Cartesian Robot.

Oriental Motor's 3-Axis SCARA Robots combined with our MRC robot controllers and MRC Studio Software allow for simple control and performance in a complete robot solution.

| Product Name | OVR3041K3-H |

OVR3046K10-H | OVR3070K3-H | |

| External View |

|

OVR Series 3-axis SCARA Robots

|

OVR Series 3-axis SCARA Robots

|

|

| Features |

Flat and lightweight

|

Large transportable mass |

Long stroke |

|

| Maximum Reach |

410 mm

|

460 mm | 700 mm | |

Maximum Transportable Mass

|

3 kg | 10 kg | 3 kg | |

| Movable Range |

1st Axis

|

±170 deg. |

±360 deg. | ±360 deg. |

| 2nd Axis | ±140 deg. | ±170 deg. | ±170 deg. | |

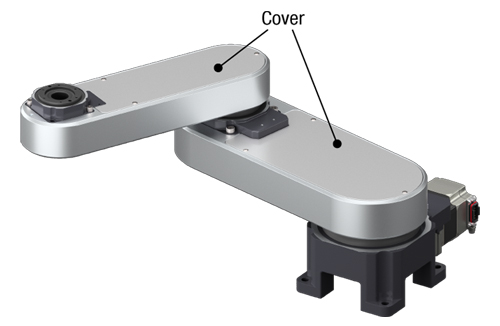

| Cover | - | With cover | With Cover | |

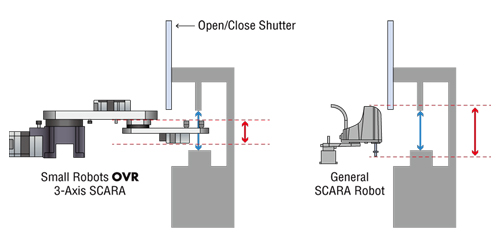

Flat SCARA Robot

Compared to general SCARA robots, the flat design allows the robot to handle narrow space, such as for attaching and detaching parts to and from equipment.

OVR Series SCARA Robot

General SCARA Robot

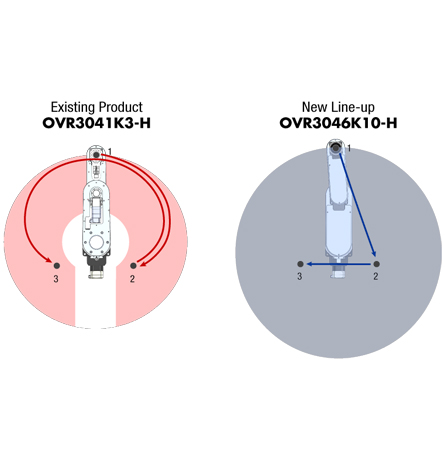

Omni-directional movement shortens takt time

The Full 360° type is capable of omni-directional motion.

Simple Dust-Resistant Structure

Products equipped with a simple dust cover are available. This cover prevents foreign matter intrusion and reduces cable abrasion.

Selectable Installation Type

Both floor mounting and ceiling mounting are available.

| Installation Type | Floor Mounting

|

Ceiling Mounting

|

| Ease of Installation | Easy |

• Robot needs to be inverted |

| Working Space |

Pallets and other components need to be placed with consideration to the robot installation space

|

Usable space directly under the robot |

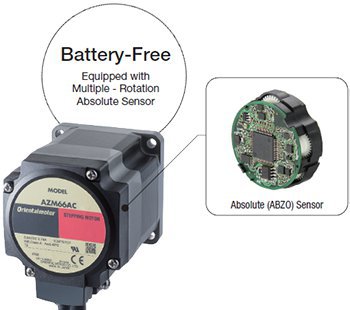

Built-in Battery-Free Absolute Encoder

| The αSTEP AZ Series (DC input) is used for all axes. No external sensors are required, simplifying the wiring. No battery is needed, so maintenance can be reduced. |  |

|---|

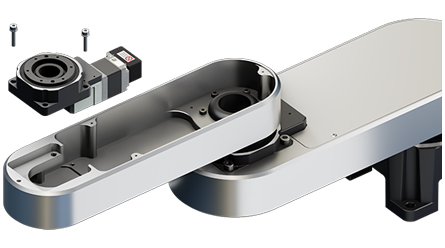

Self Maintenance is Possible

Electric actuators for each axis can be replaced by the customer. Reduces the maintenance burden (cost and time) after installation. Please contact Oriental Motor for replacement motor numbers, prices, and the replacement procedure.

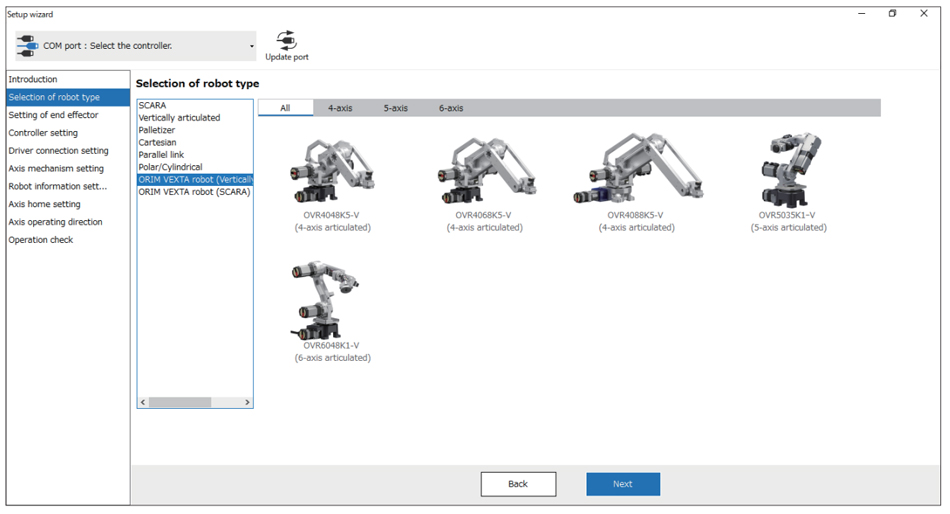

Easy Setup Quickly

Easy Setup, Even for Beginners

The OVR Series small industrial robots can help reduce setup time because dimensional data, such as arm length, is already registered with the MRC Studio software.

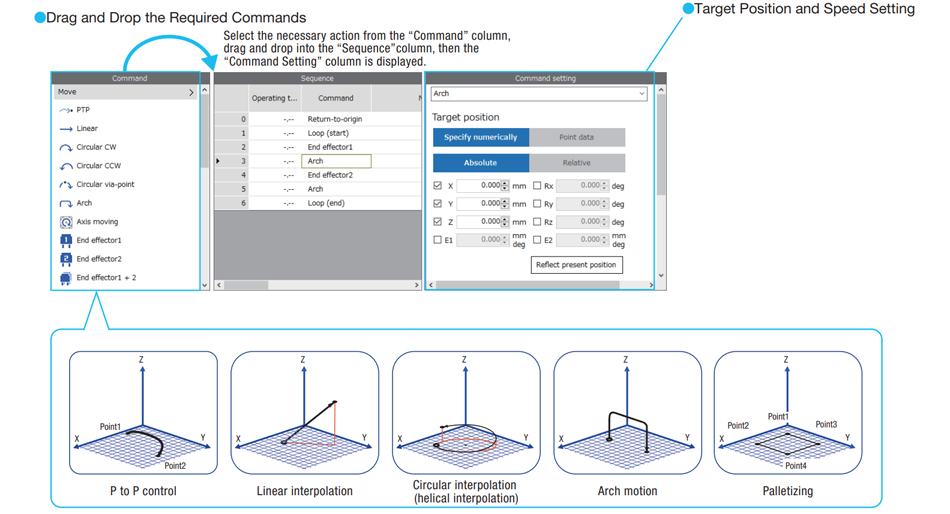

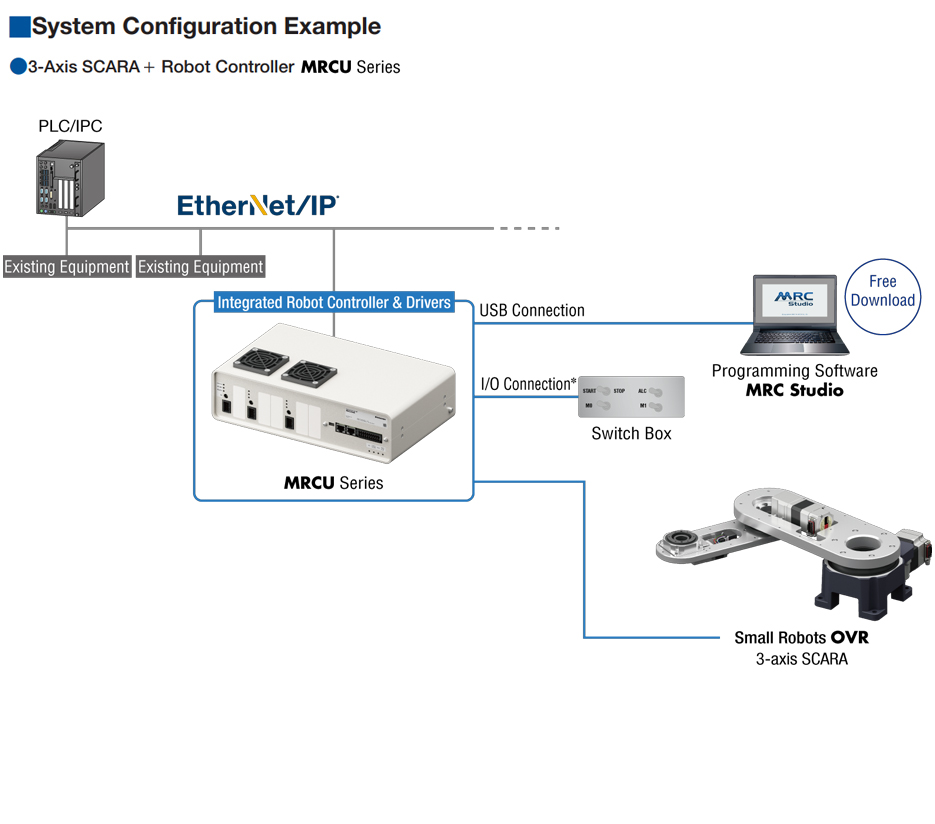

Say Goodbye to Ladder Logic! Operation Programming with Item Selection

Program creation uses a simple command selection format. Programs can be created intuitively, without requiring specialized knowledge such as ladder diagrams. The system supports a range of advanced motion control operations, including P-to-P, linear interpolation, circular interpolation, and arc motion, among others. Operating data is executed directly from a host controller via EtherNet/IP

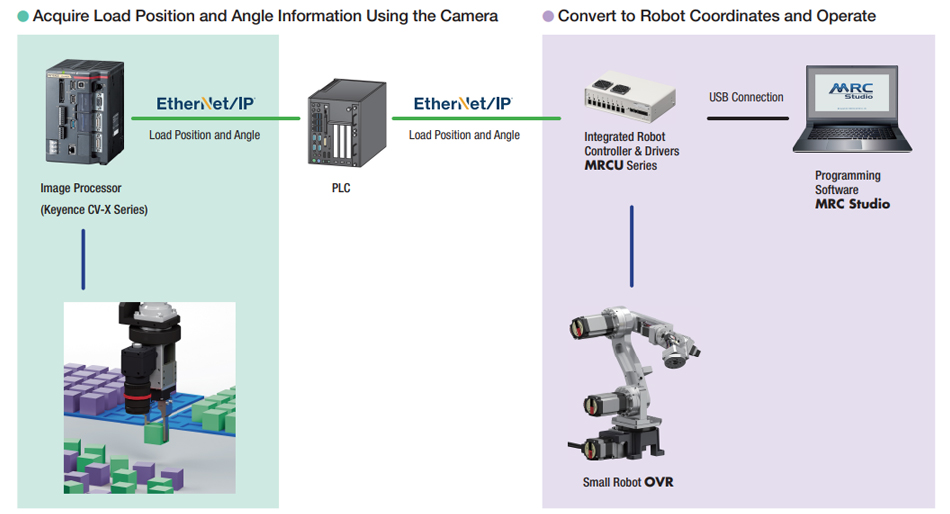

Configuration of a Robot Vision System Using 2D Cameras

The robot controller is equipped with useful functions for operating the robot using load position and angle information acquired by the camera.

In order to integrate the 2D camera, MRC Studio is used to perform the calibration* in advance. The settings can be easily configured by simply following the on-screen instructions while looking at the illustrations, allowing for a reduction in the work hours necessary for correction.

*Up to two motors

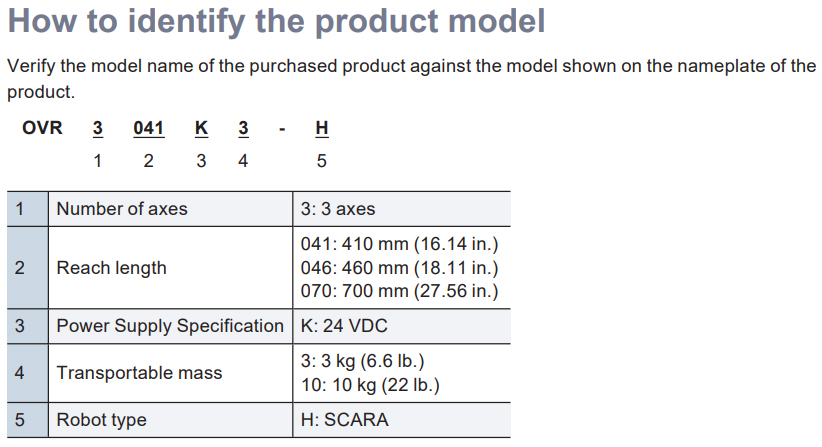

Product Lineup

SCARA Robot |

Maximum Reach (Horizontal) |

Transportation Mass |

Movable Range (1st Axis) |

Power Input |

Cover |

|

410 mm |

3 kg |

±170 deg. |

24 VDC

|

Not equipped |

|

460 mm |

10 kg |

±360 deg.

|

Equipped | |

|

700 mm |

3 kg |

Simple Control with a Robot Controller

Knowledge of "Networks", "Ladder Programs", and "Kinematics operations" is needed to run robots.

OVR Series small industrial robots utilize a simple robot controller, making it easy to start up and control the robot, even without robot control experience.

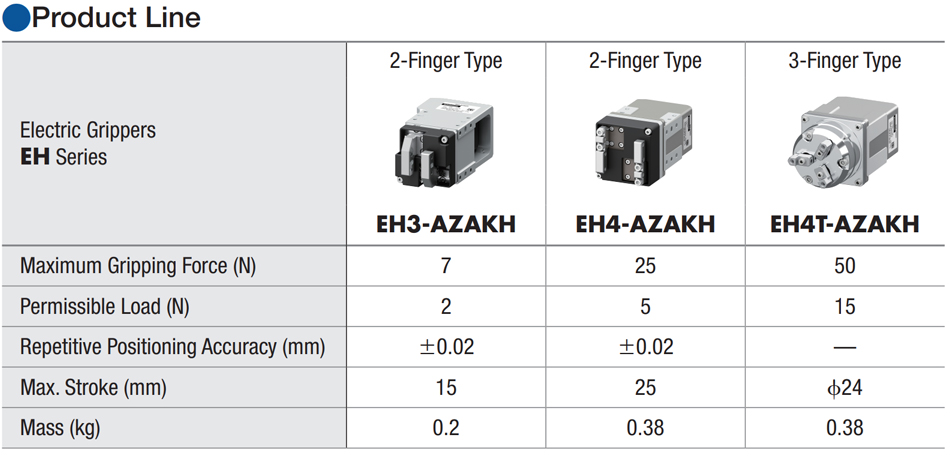

Product Line

Easy Setup with MRC Studio Programming Software

|

|

|---|

MRC Reality (AR App for Mobile)

We have an iPhone/iPad app that allows a robot to be seen in real space to simulate its operation. This simulator allows you to make the small robot OVR appear in the actual space and check its size and range of motion. Please use it to check the size and mechanism movement that are difficult to grasp from catalog information alone. Please contact our technical support for the details.

Use your smartphone or tablet

Download here for free

End Effector

The EH Series of electric grippers equipped with the αSTEP AZ Series can be controlled as an end effector by the robot controller.

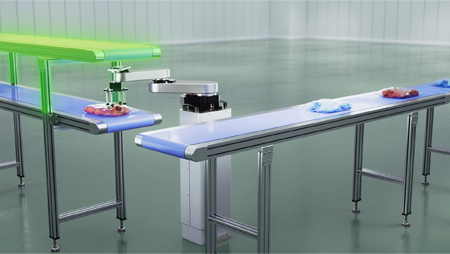

Applications

The EH Series of electric grippers equipped with the αSTEP AZ Series can be controlled as an end effector by the robot controller.

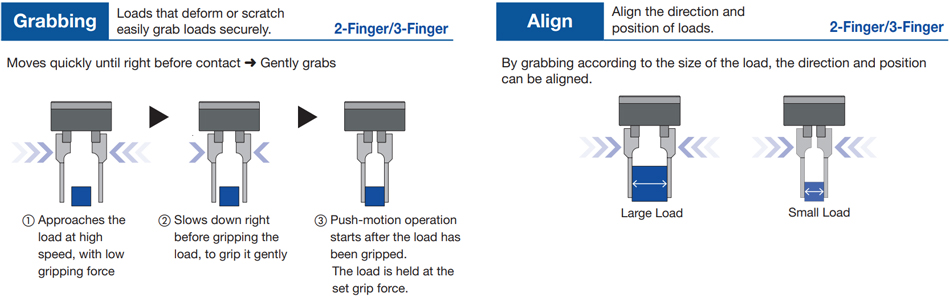

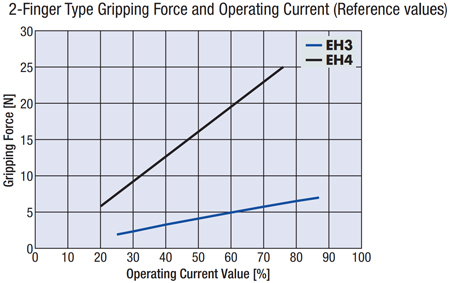

Fine Gripping Force Control

Fine current control allows the gripping force to be finely changed and adjusted.

Grips everything from delicate parts to slippery loads appropriately, gently or firmly as needed.

Mounting Brackets for SCARA

These mounting brackets can be used on OVR Series 3-axis SCARA Robots.

Connection Cables

Contact technical support

*EtherNet/IP™ is a trademark of ODVA.

*The MRCU Series can also be operated with an I/O connection (without a host controller).

- Additionally, a DC power supply and end effector are required

- Cables are sold separately

- CC09MRCU030 (3 m length) is available for the power supply cable.

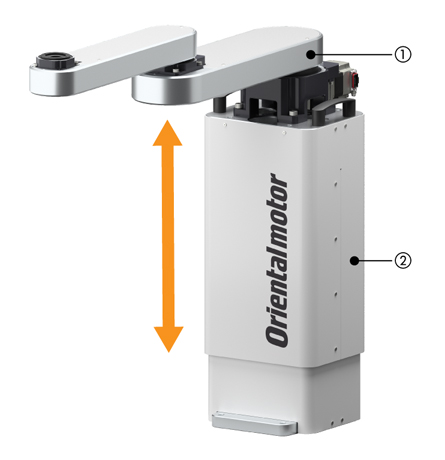

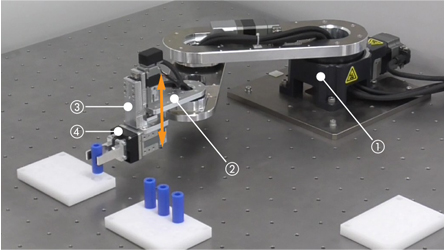

Example 1: Lifting the Robot Body

The height of the robot tip can be reduced, allowing the robot to approach narrow spaces. No horizontal barriers allow for omni-directional operation.

Installation Type: Floor-mounted, ceiling-mounted

Vertical Stroke: Short to medium (50~300 mm)

| 1 | Small Robots OVR 3-Axis SCARA |

| 2 | Electric Lifting Columns EL Series |

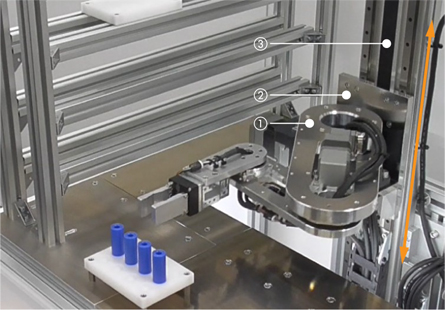

Example 2: Robot Body Vertical Operation

The height of the robot tip can be reduced, allowing the robot to approach narrow spaces. Compatible with a wide range of vertical operations.

Installation Type: Wall-mounted *For the omni-directional type, some parts cannot be moved

Vertical Stroke: Short to long

| 1 | Small Robots OVR 3-Axis SCARA |

| 2 | Mounting Bracket |

| 3 | Actuator Manufactured by FESTO EGC-HD-125-BS |

Example 3: End Effector Vertical Operation

Compact vertical operation is possible.

Installation Type: Floor-mounted

Vertical Stroke: Short (30 mm)

| 1 | Small Robots OVR 3-Axis SCARA |

| 2 | Mounting Bracket |

| 3 | Compact Electric Cylinders DR28T■■03-AZAKD |

| 4 | Electric Gripper EH Series EH4-AZAKH |

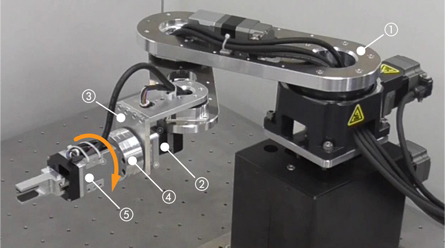

Example 4: End Effector Rotary Drive

The angle of the end effector can be changed, such as inverting the workpiece.

Installation Type: Floor-mounted, ceiling-mounted

| 1 | Small Robots OVR 3-Axis SCARA |

| 2 | AZ Series Motors + Harmonic Drive Systems Gears |

| 3 | Mounting Bracket PDG60-5 |

| 4 | Robot Flange Adapter P3F2 |

| 5 | Electric Gripper EH Series EH4-AZAKH |

Let's Make Automation Work for You!

Need Help Starting Your Automation Project? We're Here for You

Need a hand getting your automation project off the ground? Our team of robot automation experts is ready to guide you - whether you're just starting out or looking to optimize an existing setup.

Book a free session with us to get your questions answered and discover the best solution tailored to your application. Please fill out the information below, and we will have an Engineer reach out promptly to support you.