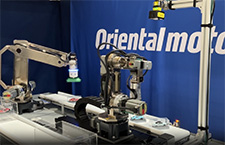

MRC Studio Software

The MRC Studio is the complimentary GUI programming software for the MRC Robot Controllers. Powerful yet easy to use, complex motion sequences for a variety of robots can be programmed easily even without prior robot programming experience. With intuitive functions such as drag and drop commands, software teaching, automatic operation time calculation, and live robot motion verification, the MRC Studio can have your robot moving in minutes.

To accelerate your learning curve, program offline with the MRC Studio Simulator software even before purchasing a robot, then seamlessly import your programs upon installation. Also available for Apple iOS smartphones, tablets, and the Meta Quest 3 head mounted display, the MRC Reality app enables visualization of the robot operating in your own production environment for optimal robot integration.

MRC Studio Features

Live Motion Simluator

The Graphic Monitor simulates the operation program live in a 3D environment, so you can visualize and verify the robot motion before implementation.

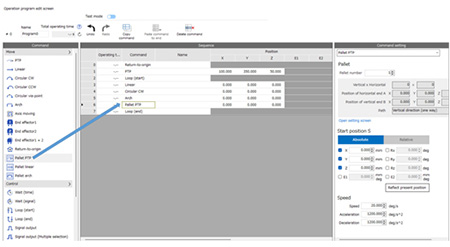

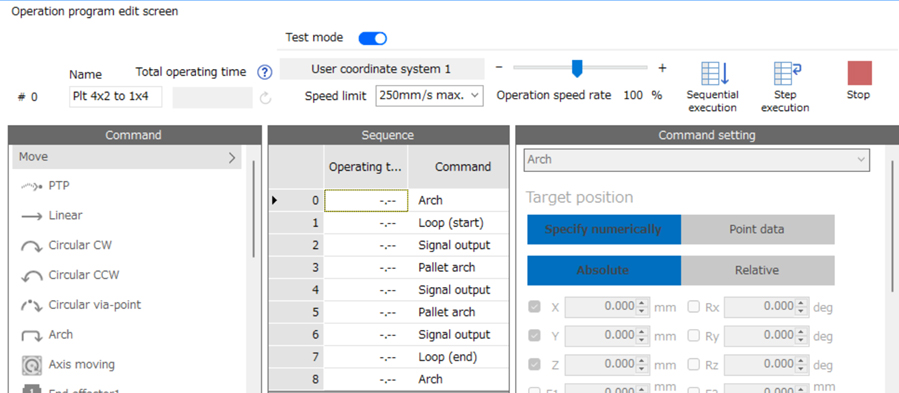

Easy GUI Programming

Simply select, drag, and drop commands from the Commands list to the Sequence window. No ladder logic knowledge is necessary.

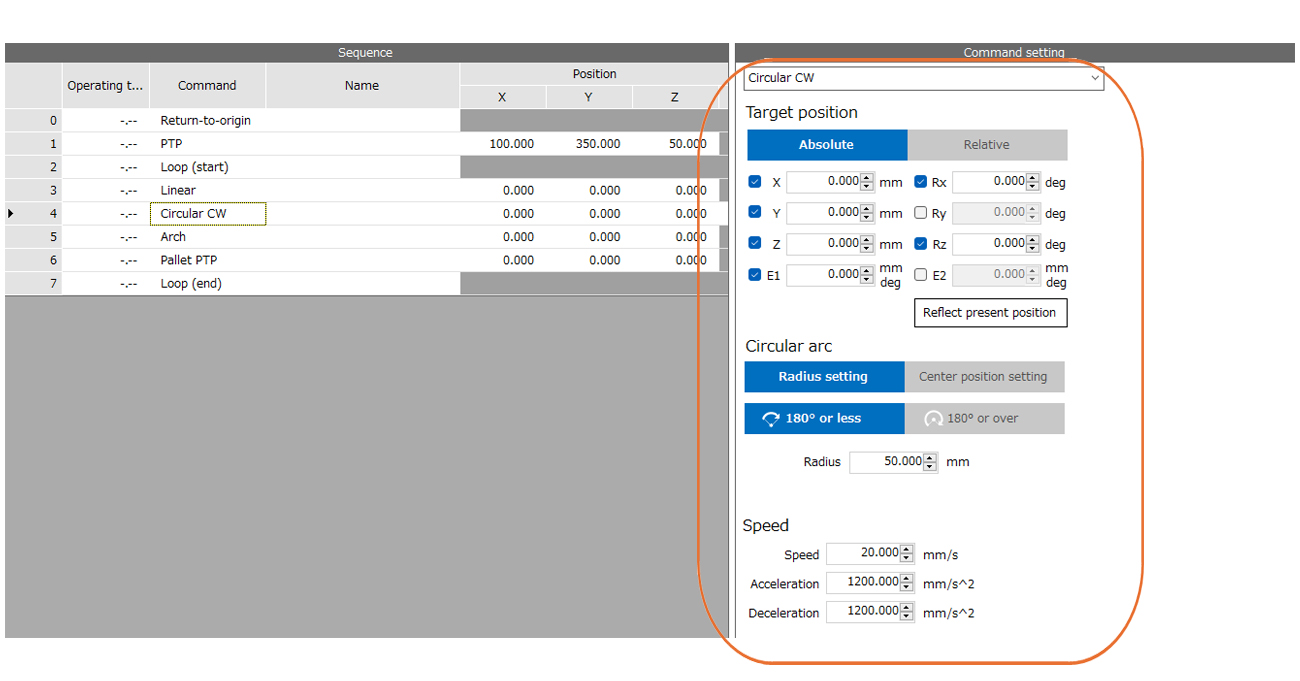

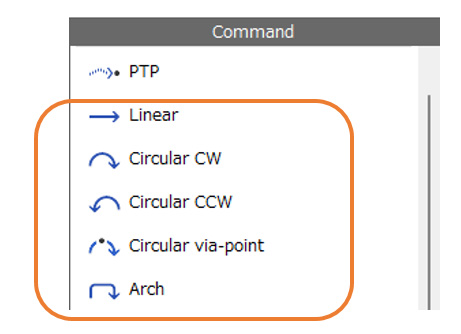

Multiple Interpolation Commands

Multiple interpolation commands make complicated motion programming simple by making sure all axes arrive at the final target position at the same time.

Configuration of a Robot Vision System Using Cameras

The built-in robot vision calibration function simplifies robot operation and reduces costs since it can use a vision system without a robot/vision coordinate calibration function.

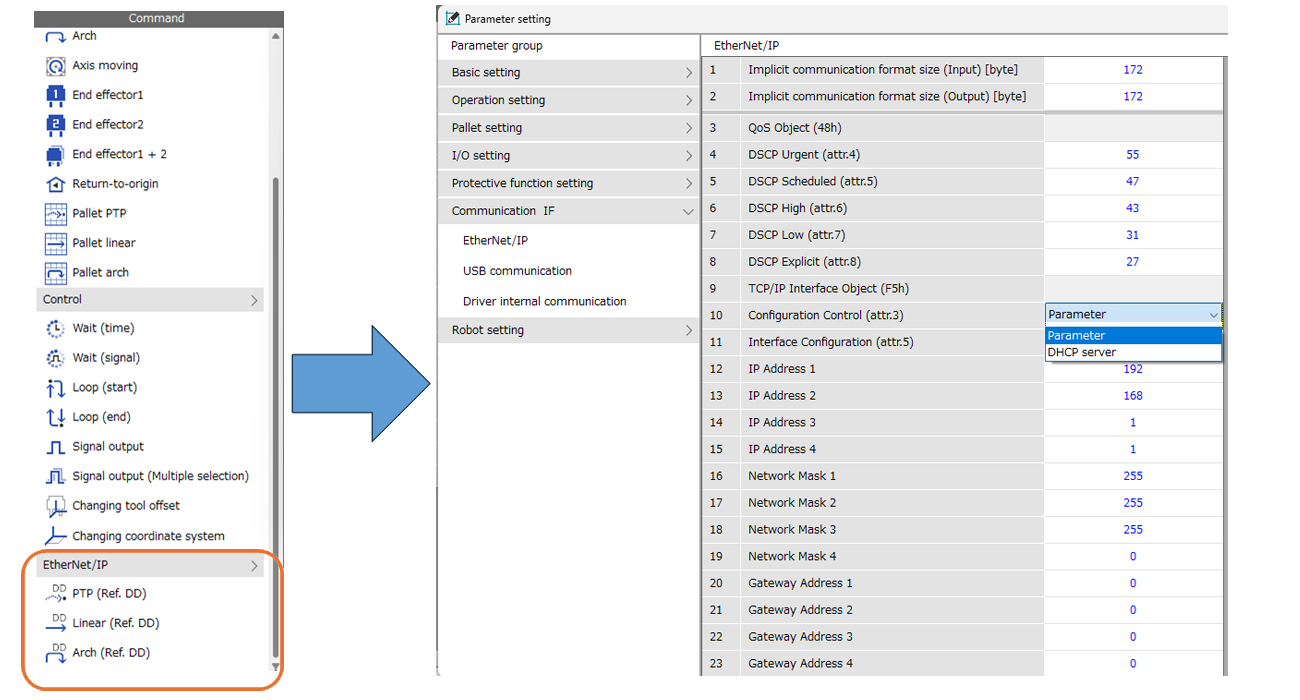

Network Control with EtherNet/IP

Various network commands are available through EtherNet/IP. For example, position data can be set using “(DD) Camera coordinate” or “(DD) Position” of the implicit message.

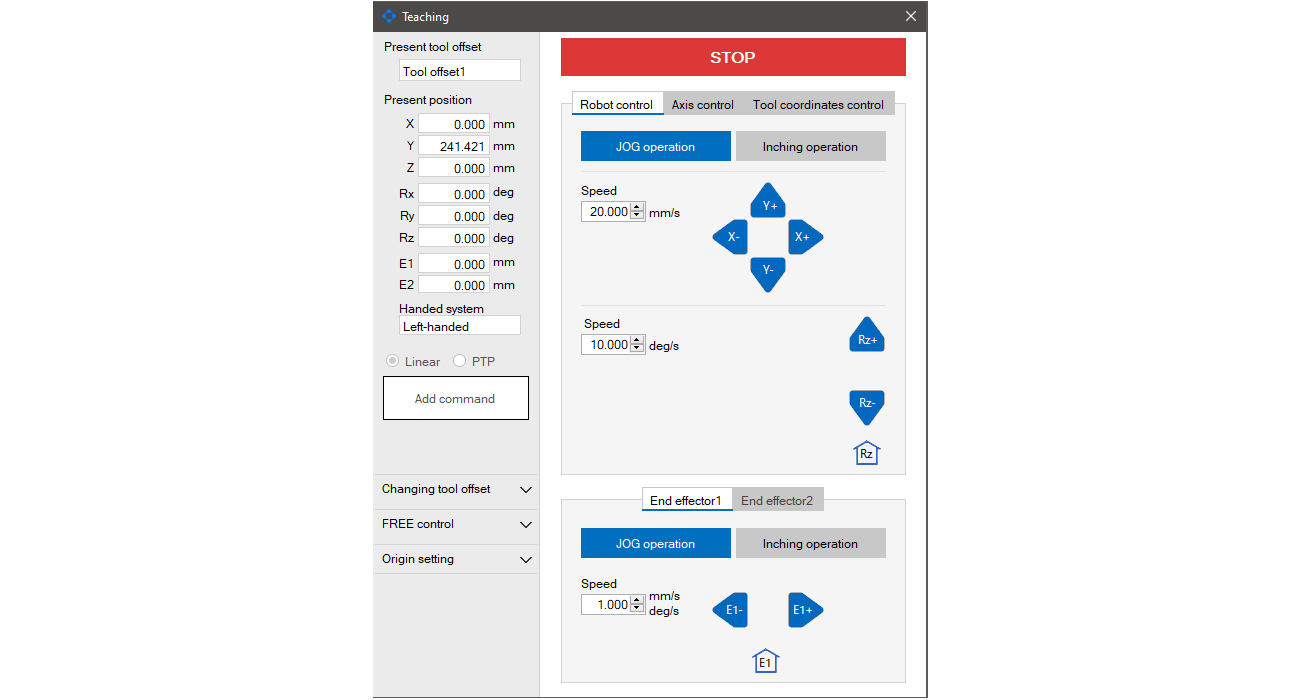

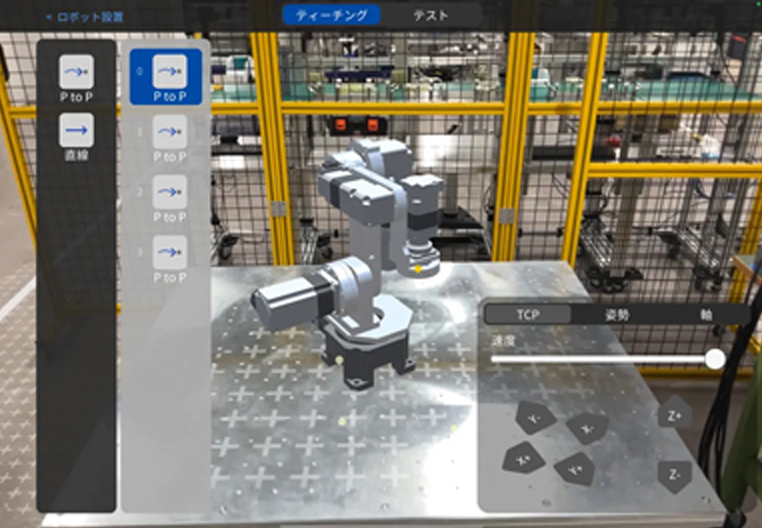

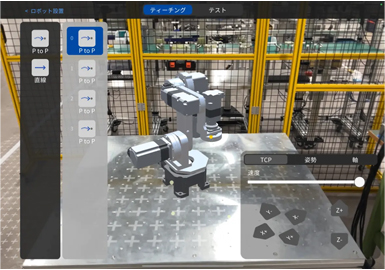

Software “Teaching”

Easily program position data with the Teaching function by robot control, axis control, tool coordinates control, JOG operation, inching operation, present positions of each axis, and more.

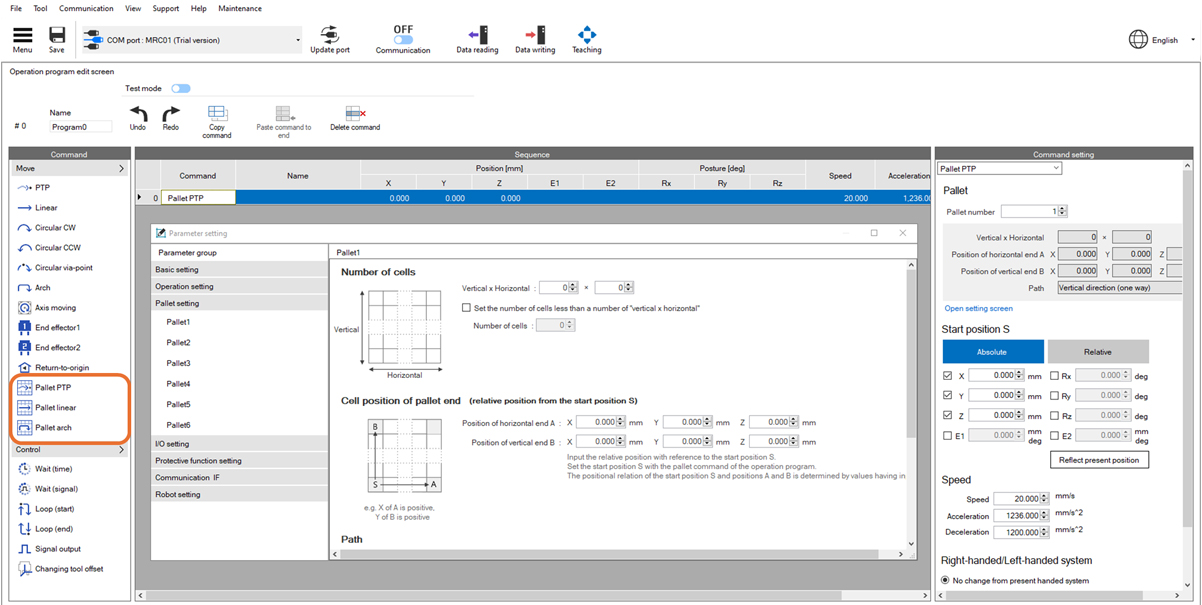

Pallet Commands Simplify Complex Motion Programming

Pallet commands can combine multiple moves into one complex motion, saving time and energy required for programming motion for pallet pick and place operations.

Test Mode (Sequence or Step Execution)

Test mode is helpful during motion sequence programming. Use this function to verify the motion before adding the command to the program.

Software Coordinates Programming

Easily plot target positions in X, Y, and Z coordinates in the Commands Setting window.

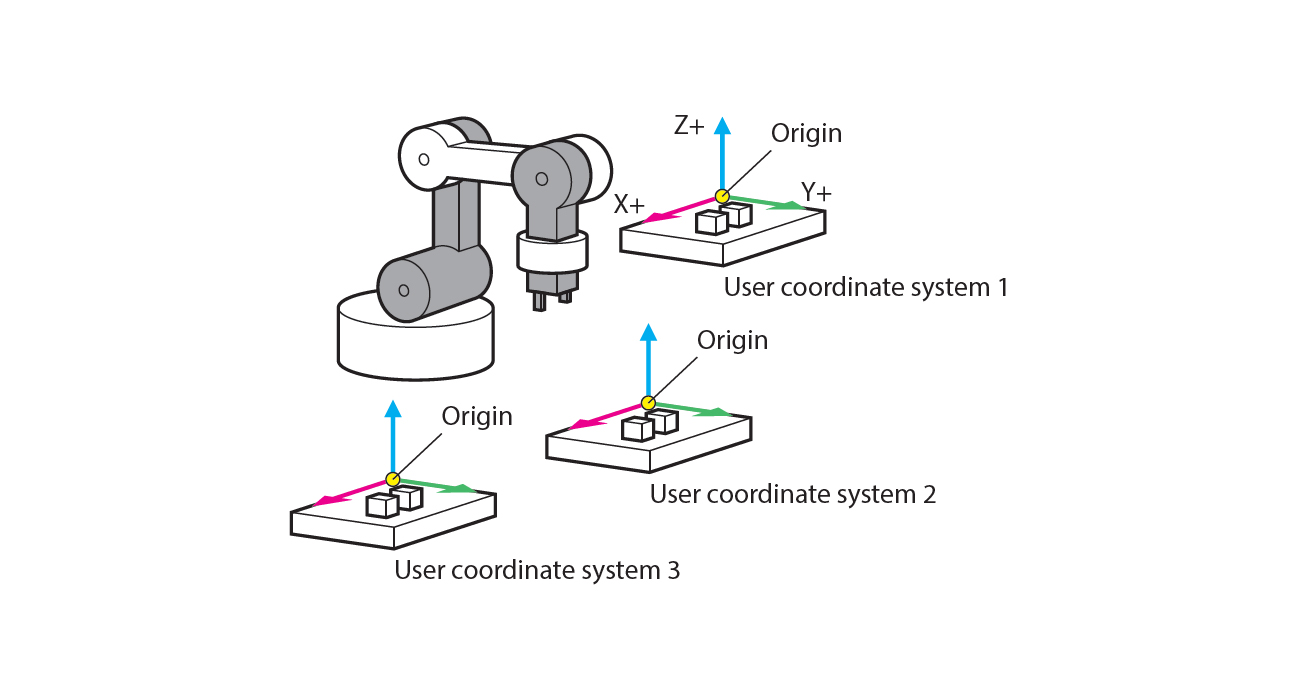

Multiple “User Coordinates Systems”

Change the user coordinates system according to your preference to make complicated motion sequences easier to program.

MRC Studio Simulator

Expedite the startup time by simulating the robot in your own environment and importing data from the MRC Studio Simulator software.

| Feature | MRC Studio (Product Version) |

MRC Studio Simulator |

|---|---|---|

Communication with Robot Controllers

|

◯ | - |

| Setup | ◯ | △ |

| Items that communicate with robot controllers or drivers cannot be set. | ||

Save Configuration Data File to PC

|

◯ | ◯ |

| Open File | ◯ | ◯ |

| The .mrcx file can be opened. | The .mrcxt file can be opened. A sample file of the configuration program is also available. |

|

Import Data Files Created With MRC Studio Simulator

|

◯* | - |

Teaching

|

◯ | ◯ |

Operation Program Creation

|

◯ | ◯ |

Test Operation

|

◯ | ◯ |

| Parameter Setting | ◯ | △ |

| Some parameters cannot be set. For more information, please refer to [Help] → [Open how to use] in MRC Studio Simulator. |

||

| Monitoring | ◯ | △ |

The following can be monitored. • TCP coordinates of the robot

Information on signal systems that require connection to external devices cannot be monitored. |

*The MRC Studio Simulator does not take into account the load condition of each axis, which may cause differences in actual operation. When operating the actual device for the first time, we recommend that you try a lower operating speed rate.

MRC Reality App

Using a smartphone/tablet or head-mounted display, use the MRC Reality to simulate the robot in its environment and confirm the size and movable range of the robot.

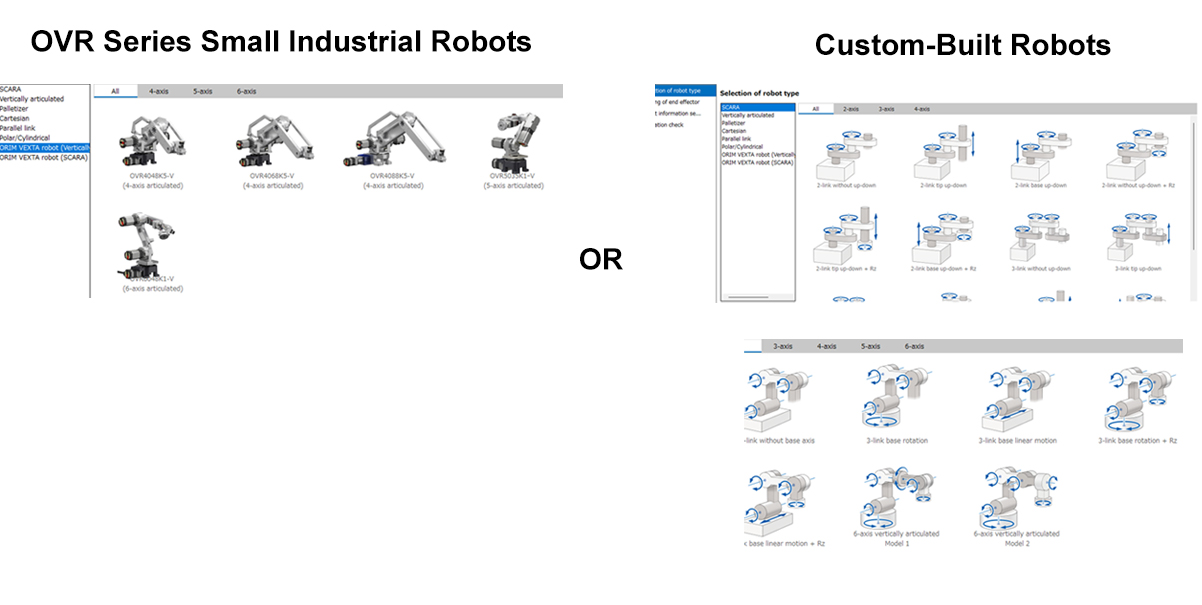

Programming Support for 2 Types of Robots

The MRC Studio Software can be used to program OVR Series small industrial robots or custom-built robots using the αSTEP Hybrid Step-Servo Product Family.

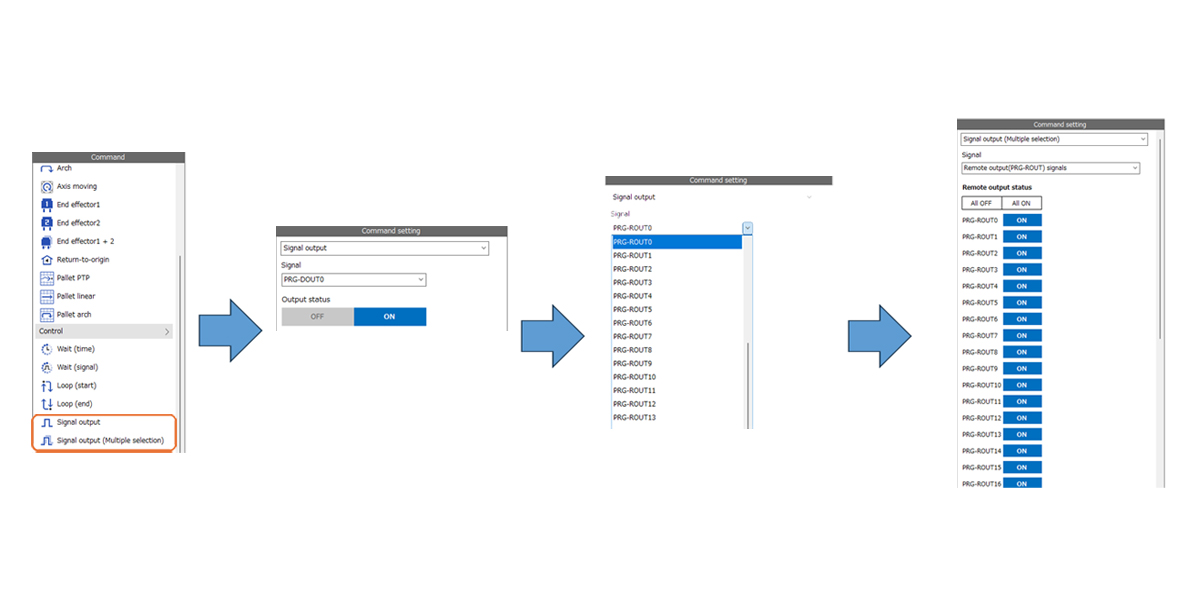

External Device Control

Use Signal Output to control 3rd party devices with Direct I/O or Remote I/O.

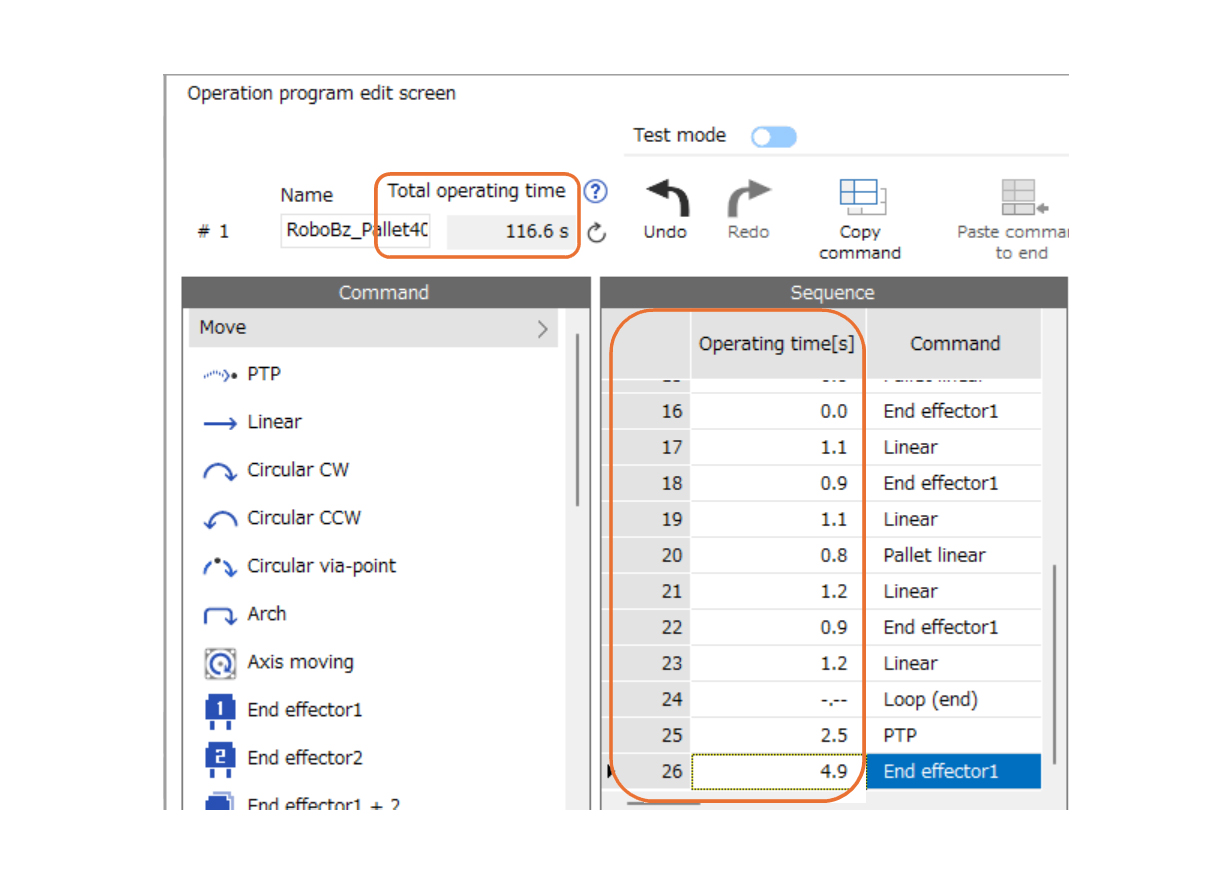

Automatic Operation Time Calculation

The Total Operating Time is automatically calculated in the Operation Program Edit Screen.

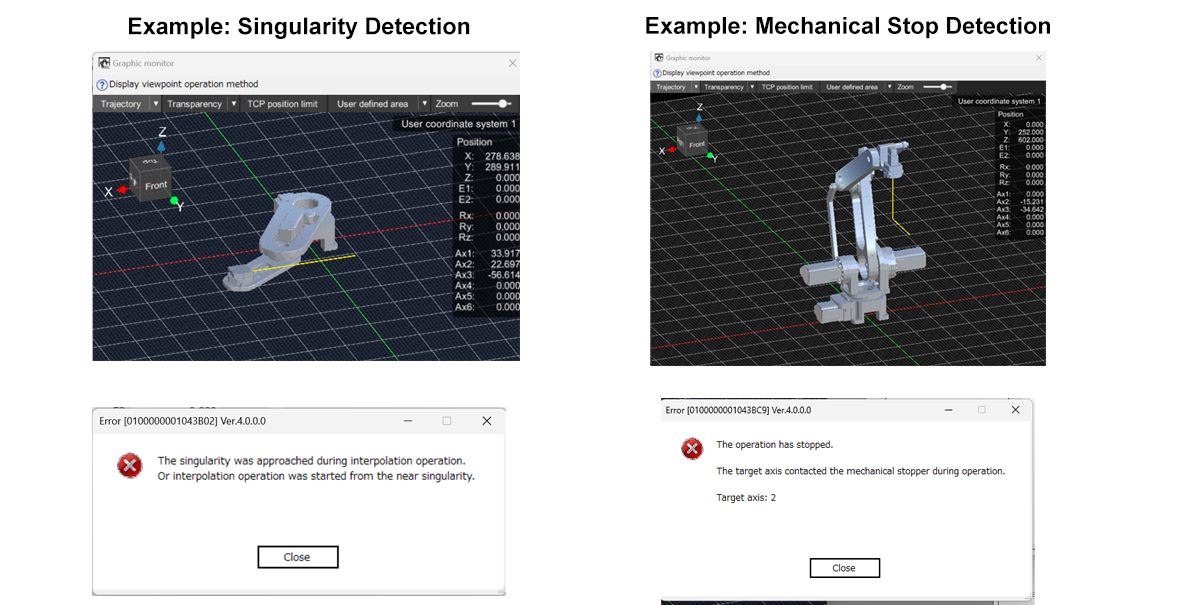

Automatic Singularity and Mechanical Limit Detection

Singularity and mechanical stops can be detected automatically to prevent damage and improve safety.

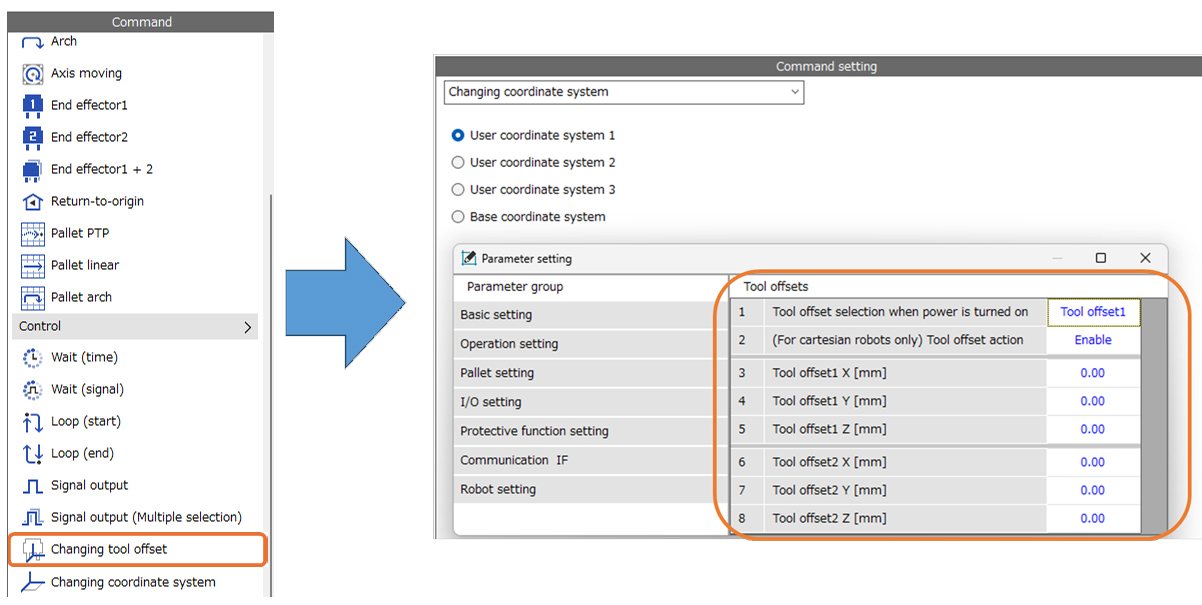

Multiple “Tool Offset” Parameters

In the Changing Tool Offset menu, various “Tool Offset” parameters are available to program multiple end-effectors.

MRC Studio Software

MRC Studio Software Requirements

MRC Studio is a programming software that supports everything from startup to maintenance. A computer can be used to create operation programs, edit various parameters, perform teaching, and monitor various statuses.

Windows 10 Ver 1607 or later.

*After programming MRC robot controller with MRC Studio Ver.3.0.0.0 or later, do not program with earlier versions of MRC robot controller. Data read/write cannot be executed normally, and the data in MRC robot controller may be changed.

Note: The MRC Studio Simulator may operate differently than the product version. Also, communication with the MRC robot controller is not possible. When connecting with MRC robot controller, please use the product version software.

Communication Cable:

Prepare a USB cable (commercially available) with the following specifications.

Standard: USB 2.0 (full speed)

Cable: Length: 3m or less, Shape: A to mini-B

Device Driver:

Device drivers are automatically installed when you install MRC Studio. Use it only if the device driver could not be installed with MRC Studio.

The device driver download file contains 32-bit and 64-bit versions. Please choose according to your environment.

ORIENTAL MOTOR USB Common Virtual COM Port Driver Windows 10

MRC Studio Simulator:

Updated: 5/14/2024

MRC Studio Simulator is available for users who wish to test before purchasing the MRC robot controller. With the MRC Studio Simulator, you can create, execute, teach, set home, and operate programs while viewing the robot's 3D graphics. The download file contains sample data files for each robot type, so you can try it immediately after installing the MRC Studio Simulator.

Ver.4.0.0.0

Windows 10 Ver.1607 or later

MRC Reality

This simulator allows a small robot OVR to appear in a real space to check its size and movable range. Please use this information to confirm the size and movement of the mechanism, which are difficult to grasp from the catalog information alone.

Overview

Using a smartphone/tablet or head-mounted display, a virtual robot can be installed and operated in a real space. By actually trying the robot in the location where you want to install it, you can visually confirm the movement of the robot arm, the size of the robot arm when installed, and the space required for its movement.

Note

- The simulation in this app does not guarantee the actual design, size, movable range, etc. of a robot. Please refer to the product page for specifications when actually installing a robot.

- Please be aware of your surroundings when using this app.

Download

Operation Method

EZED2 Data Editing Software, v1.5

Last Updated on: 5/5/2014

* Please download USB driver to use CC05IF-USB with EZED2 software.

With this software, you can set and edit various data on supported linear actuator product controllers from a PC. The software also provides various monitoring functions. A PC interface cable for connecting the controller and PC is available separately.

Controllers supported by EZED2 Data Editing Software include

- EZSII Series

- SPV Series

- PWAII Series

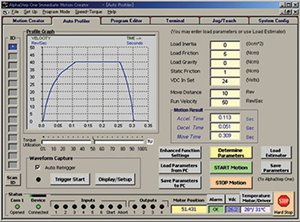

ASX All-in-One Step Immediate Motion Creator (IMC) Software, v1.41

Last Updated on: 12/4/2009

- Create motion profiles and execute them immediately

- Full system configurability

- Auto Profile Function

- I/O monitoring

- Multi-axis control

- Waveform capture

- Drag and drop programming capability

- Upload/Download programs and parameters

- Built-in terminal function

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)