Investing in Automation

As labor-saving efforts continue to progress, automation using robots is increasingly in demand. For those of us using traditional manufacturing, learning about and determining the long-term benefits of investing in Automation is a technology wave everyone is jumping on. Oriental Motor is here to help you start the journey. Many customers have never used robots before and are unsure whether robots can achieve what they need. Consult with us today for a free consultation.

When are robots worth the investment?

Some business owners face the exciting challenge of deciding which task to automate first. Others are uncertain whether robots can deliver a substantial return on investment (ROI) for their company. Robots are worth the investment when they significantly reduce labor costs, increase efficiency, or improve safety. They’re ideal for repetitive tasks and/or high-precision work. Consider factors like long-term savings, scalability, and return on investment (ROI) before committing. Robots are a great value, especially for tasks that require consistent, high-quality output.

Case Study

Investing in robots and automation enhances efficiency, reduces operational costs, and boosts productivity. Read this case study that demonstrates a working example of the warehouse work roles: Picking, Packing, Shipping, Receiving, Unpacking, and Stocking.

What is the best approach for you when considering the introduction of a robot to your facility for the first time?

Like any new technology, the use of robotics can be learned. Approach your entry into robotics with realistic expectations. Consider which of these scenarios applies to your situation.

Scenario 1:

Your company has limited knowledge of automation and would require a System Integrator to assess and then design, install, and maintain your robot process. Best to contact a System Integrator who will evaluate your desired results and design an automated solution from start to install, along with a maintenance program.

Best to contact a System Integrator who will evaluate your desired results and design an automated solution from start to install, along with a maintenance program.

OR

Scenario 2:

Your company has an Engineering department and would work with a System Integrator, where your Engineering team would take over the program and maintenance after installation

Similar to scenario 1, however, your engineering team would learn from the system integrator, be actively part of the design process, along with the installation and future maintenance.

OR

Scenario 3:

Your company has experience in automation and assessing risks and is in need primarily of specific system education and technical support, primarily through the evaluation and installation process

Your engineering team will evaluate all aspects of the automation project at the component level, from design to risk assessment, leading to installation, programming, and maintenance.

How do you ensure the safety of your team when introducing robots?

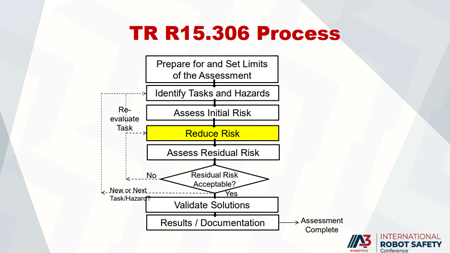

Safety is paramount for any company. Not only is it critically important, but a thorough risk analysis must be conducted during the early planning stages of any automation solution to ensure all workers and potential hazards or future challenges are addressed at an early stage. If this is out of your scope, hiring a reputable system integrator for this step can easily help walk you through things to consider. Start with the type of automation and robot output needed and the workspace in which the automation will be working. Additional equipment, like sensors, scanners, and optical barriers, is essential in most cases and should be part of the assessment.

ISO 12100 is a baseline from which to start. RIA TR R15.306-2016 is a task based risk assessment methodology that satisfies ANSI/R15.06.

Depending on which scenario your company falls under, will determine who and where this process can be achieved.

Source: https://www.automate.org/userAssets/a3/events/file/Jeff%20Fryman%20-%20Risk%20Assessment.pdf

How Can Oriental Motor Help You Start?

Need a hand getting your automation project off the ground?

Our team of robot automation experts is ready to guide you - whether you're just starting out or looking to optimize an existing setup.

Book a free session with us to get your questions answered and discover the best solution tailored to your application.

Can we see the actual robots in person?

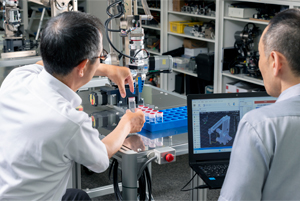

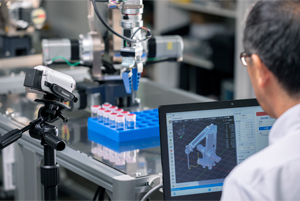

Yes, we have established a Proof of Concept Lab at our Chicago office, a facility designed to support customers in implementing automation and introducing robots.

If video is best, schedule a live video meeting where we can demonstrate your designed robot type.

Proof of Concept Lab

We can test customers’ requests with our products and assess combinations with peripheral devices like cameras, third-party grippers, conveyors, and encoders. Please feel free to contact us.

Capabilities of the Proof of Concept Lab

If you want to perform pick-and-place using a robot, you can schedule and then send the object you want to move to our lab. Our team will use the OVR robot and other necessary components and send a video of the operation back to the customer. From this, you can determine if the OVR robot meets your request.

Besides the Proof of Concept Lab, are there any other types of support?

Yes. To reproduce the movements simulated in the Proof of Concept on an actual production site, our engineer can visit your site and support you in achieving the desired operations in your production environment.

How is the programming of a robot done?

For all of our OVR robots, we use our MRC Controller and free software. The MRC Studio is a software tool for controlling OVR robots. Powerful yet easy to use, complex motion sequences for a variety of robots can be programmed easily, even without prior robot programming experience. A simulator version of the programming software is also available for free to allow customers the chance to experience the operation before purchasing a robot system. We also offer training on how to edit these programs, which are held regularly at our Chicago office. This training can also be conducted at your location.

Our team of robot automation experts is ready to guide you - whether you're just starting out or looking to optimize an existing setup.

Book a free session with us to get your questions answered and discover the best solution tailored to your application.

Our Robot Message: Oriental Motor USA offers a complete line of Automated robots (OVR Series) along with a simple-to-use, powerful robot controller, and easy-to-use software that will allow you to integrate automation easily into any work cell where repeatable processes are required.

4-Axis |

5-Axis |

6-Axis |

3-Axis |

3-Axis |

|

|

|

|

|

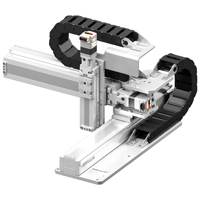

Is an OVR Series SCARA, Cartesian, or Articulated robot right for your environment and long-term goals?

When choosing between a SCARA, Cartesian, or Articulated robot, it’s essential to consider your environment and long-term goals. When used with sensors, cameras, and conveyors, a work cell can be easily transformed into a highly productive, high-quality workstation. In case maintenance is required, some motors that are used on these robots can be replaced by the customer. This helps reduce the maintenance cost and time after installation.

Articulated robots, resembling a human arm, offer flexibility and a wide range of motion, making them suitable for complex tasks like welding, painting, or handling irregularly shaped objects. While they require more space and are more expensive, they are the best choice for dynamic, highly flexible operations in diverse environments.

SCARA robots excel in high-speed, precise operations, making them ideal for assembly, pick-and-place tasks, and small parts handling in constrained spaces. They offer speed and repeatability but are limited in their range of motion.

Cartesian robots, with their linear axes, provide excellent precision and are suitable for tasks that require large movements in 3D space. They’re perfect for applications like CNC machining or packaging applications, offering scalability and flexibility, though they can be slower compared to SCARA robots.