Semiconductor Case Study - Fully Closed Loop Control

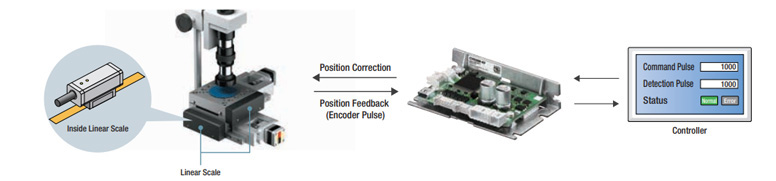

Accepting Third Party External Sensor Input, Fully Closed Loop Control Allowing for Correction

In semiconductor manufacturing processes, where the trend toward making the machine footprint smaller continues, improving alignment accuracy is an issue in many cases. The use of fully closed-loop control in motion control drivers saves space, simplifies electronics, and provides direct feedback for the mechanism position, allowing for the correction of any deviations between the command position and the feedback position.

Stepper motors are a desired motor solution for their simple programming, high accuracy, and repeatable positioning performance. Using a stepper driver that accepts third-party feedback by using an encoder, such as a linear scale, can reduce the error between the commanded coordinate values and the actual coordinate values, allowing for extremely high position accuracy. Featured below, this stepper driver allows for the operation to correct the position, referring to position deviation based on position information detected by a linear scale or rotary encoder installed at the end of the machine. This allows for operation with high reliability and positioning accuracy at a reasonable price.

Challenge:

- Improvement of Positioning Accuracy

- Hunting

- Vibration Control

Solution:

- CVD Series Fully Closed Control Type Drivers

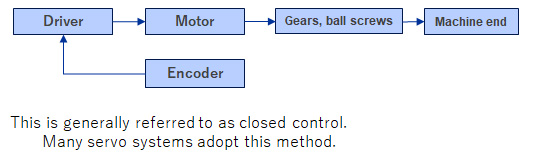

Semi-Closed Control |

|

Method: The rotation angle of the motor is detected by an encoder to predict the position of the machine end. Feature: Errors occur between command values and actual coordinate values due to effects such as ball screw pitch errors, expansion, contraction, deflection, and backlash caused by high-speed rotation. Accuracy: Depends on backlash and lost motion |

|

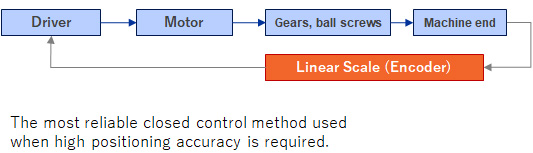

Fully Closed Control |

|

Method: The position of the machine end is directly detected using an encoder such as a linear scale. Feature: There is little error between the commanded coordinate values and the actual coordinate values, which allows operation with extremely high positioning accuracy. Accuracy: No backlash or lost motion effects. It depends on the minimum resolution, indication accuracy, and installation precision of the encoder. |

|

CVD Series Fully Closed Control Type Drivers

The use of fully closed-loop control, which provides direct feedback for the mechanism position, allows for the correction of any deviations between the command position and the feedback position.

- Fully Closed-Loop Stepper Motor Control

- Enables High Precision Positioning

- No Gain Adjustment or Hunting with Stepper Motors

Compatible Motors and Actuators

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-468-3982