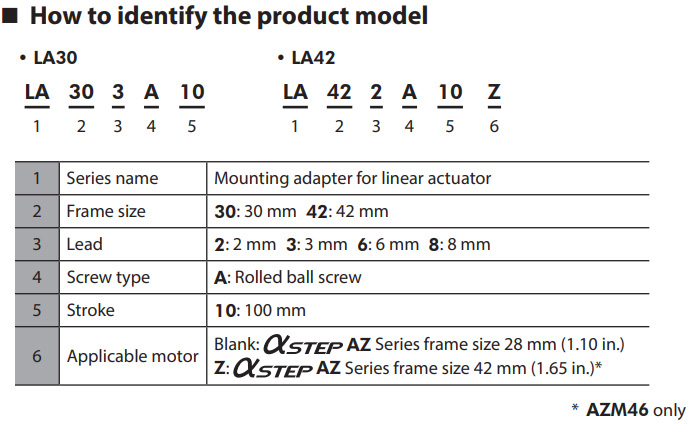

Linear Actuators > Linear Actuator Attachments > Rolled Ball Screw Linear Actuator Attachment for Stepper Motors

Rolled Ball Screw Linear Actuator Attachment for Stepper Motors

Rolled Ball Screw Linear Actuator Attachment for Stepper Motors

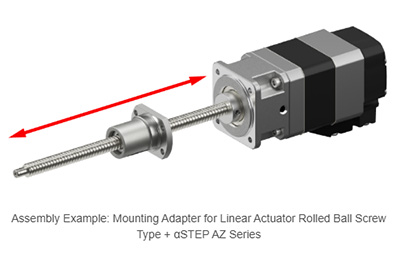

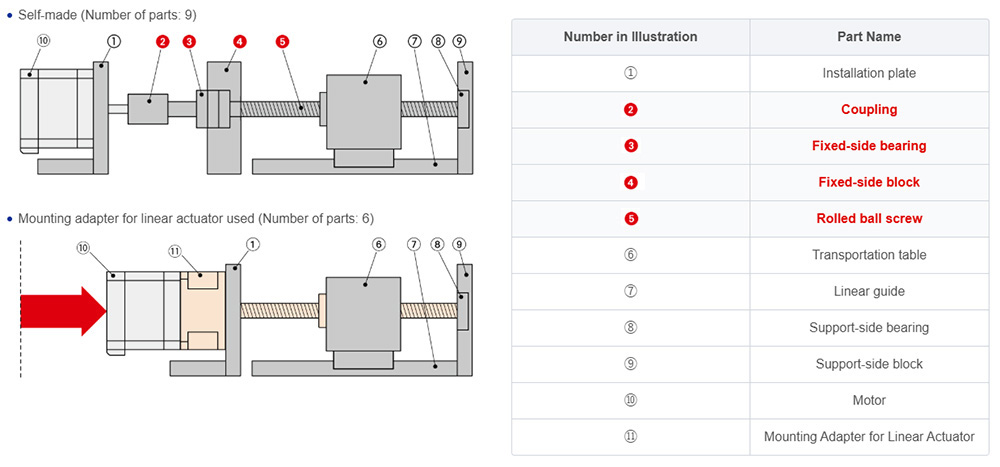

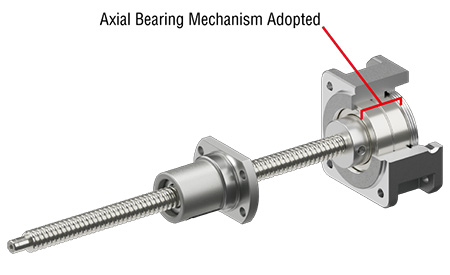

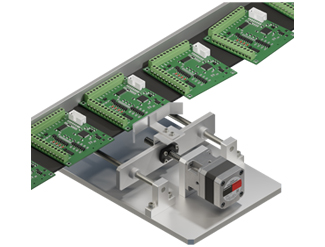

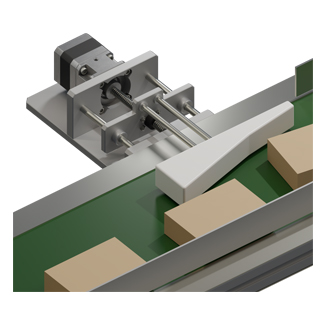

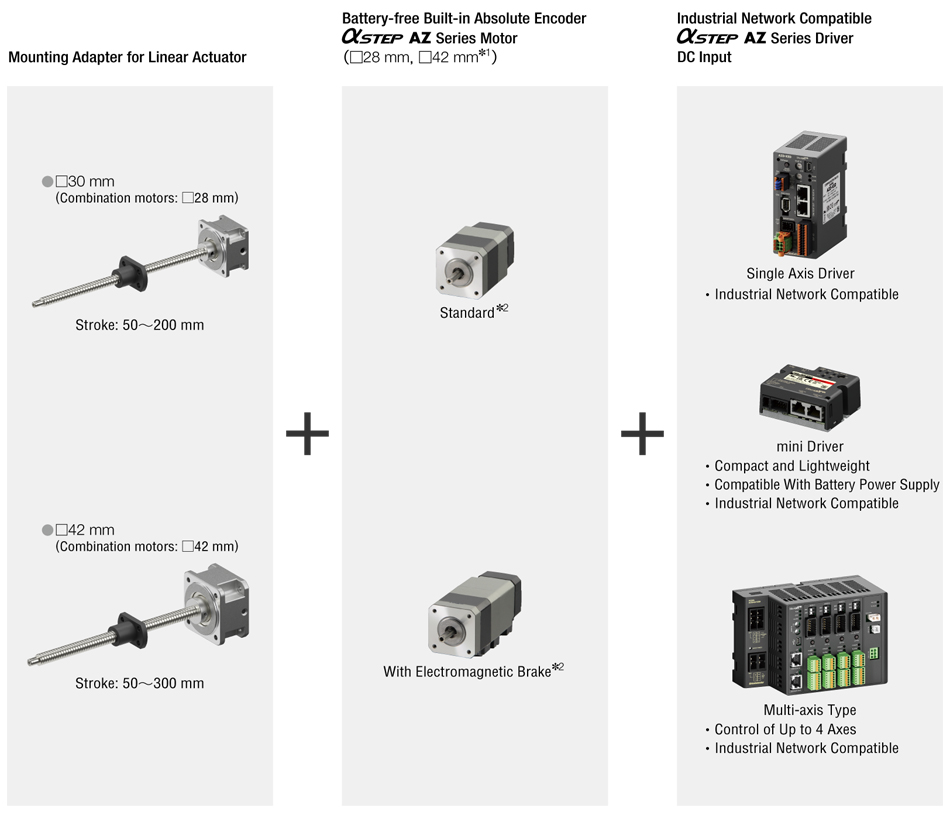

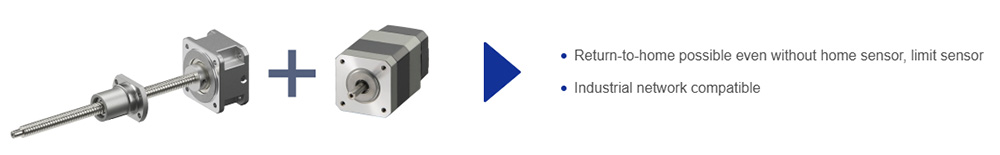

The Mounting Adapter for Linear Actuators is a linear motion mechanism with a rolled ball screw and iron nut. It saves space and reduces design time compared to a custom-built mechanism. Use these with 28 mm and 42 mm frame size AZ Series Hybrid Step-Servo motors with multi-turn absolute position control and sensorless homing.

- Linear motion mechanism with a rolled ball screw and an iron nut

- Easy installation without the need of coupling to an Oriental Motor stepper motor

- Repetitive positioning accuracy of ±0.01 mm

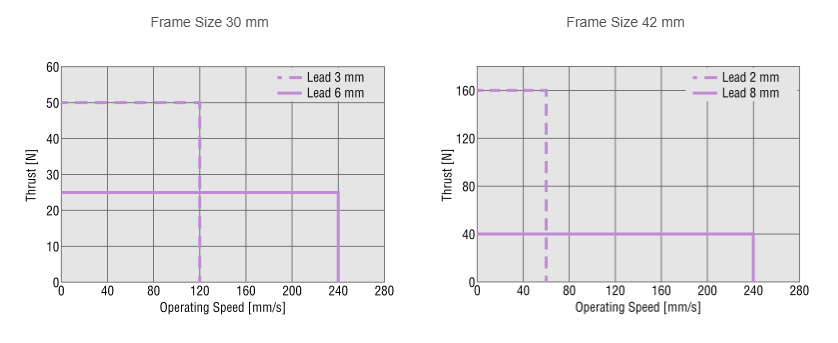

- For the 30 mm frame size, thrust force is at max. 50 N

- For the 42 mm frame size, thrust force is at max. 160 N

Linear Actuator Attachment

αSTEP Hybrid Step-Servo

Compact Linear Actuators