AC Input Stepper Motors Drivers

Absolute Type Stepper Motor Drivers

αSTEP AZ Series Closed Loop, Absolute Type Stepper Motor Drivers

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherNet/IP™, EtherCAT, PROFINET Compatible Types

- Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with AlphaStep AZ Series Motors (AC Input)

![]()

![]()

Closed Loop Stepper Motor Drivers

αSTEP AR Series Closed Loop Stepper Motor Drivers

- Built-in Protective Functions

- Pulse Input or Built-in Controller (Network) Types

- Single-Phase 100-115, 200-240 VAC or Three-Phase 200-230 VAC

- For use with AlphaStep AR Series Motors (AC Input)

5-Phase Stepper Motor Drivers

RKII Series 5-Phase Microstepping Stepper Motor Drivers

- High Efficiency, Low Vibration, Microstepping Driver

- Pulse Input or Stored Data (Network Compatible) Type

- Built-in Protective Functions

- Single-Phase 100-120 or Single-Phase 200-240 VAC

Types of Stepper Motor Drivers

Drivers that operate in the pulse input mode and built-in controller mode are available. You can select a desired combination according to the required operation system.

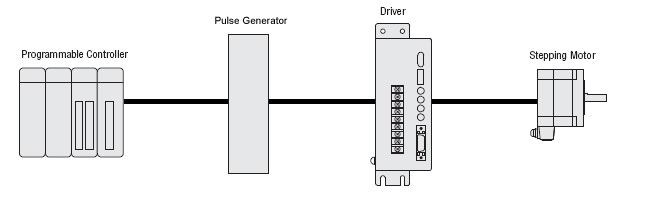

Pulse Input Drivers

The stepper motor can be controlled using a pulse generator provided by the user. Operation data is input to the pulse generator beforehand. The user then selects the operation data on the host programmable controller, then inputs the operation command.

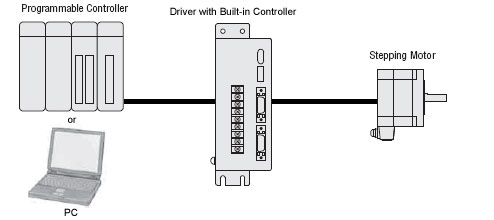

Built-in Controller (Stored Data or Stored Program) Type Drivers

The built-in pulse generation function allows the motor to be driven via a directly connected personal computer or programmable controller. Since no separate pulse generator is required, drivers of this type save space and simplify wiring.

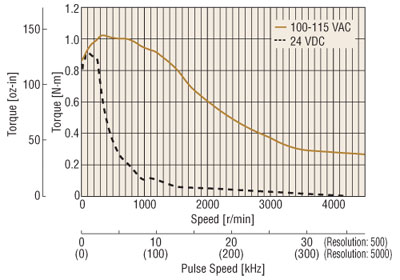

Difference Between AC Input and DC Input Characteristics

A stepper motor is driven by a DC voltage applied through a driver. In Oriental Motor's 24 VDC input motor and driver systems, 24 VDC is applied to the motor. In the 100-115 VAC motor and driver systems, the input is rectified to DC and then approximately 140 VDC is applied to the motor (certain products are exceptions to this.)

This difference in voltage applied to the motors appears as a difference in torque characteristics at high speeds. This is due to the fact that the higher the applied voltage is, the faster the current rise through the motor windings will be, facilitating the application of rated current at higher speeds. Thus, the AC input motor and driver system has superior torque characteristics over a wide speed range, from low to high speeds, offering a large speed ratio.

It is recommended that AC input motor and driver systems, which are compatible over a wider range of operating conditions than DC input systems, be considered for your application.

Stepper Motor Driver Comparison

Product Series |

|||

Features |

Main Series for Motor / Actuators |

Closed Loop / Resolver Based |

High Efficiency, Low Vibration, Microstepping Driver |

Data Support Software (MEXE02) |

Yes |

Yes |

Yes |

Motor Series required |

AZ Series |

AR Series |

RKII Series |

Input Powers |

Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC |

Single-Phase 100-115, 200-240 VAC or Three-Phase 200-230 VAC |

Single-Phase 100-120 or Single-Phase 200-240 VAC |

Available types / options |

Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherNet/IP™, EtherCAT or PROFINET Compatible Types |

Pulse Input or Built-in Controller (Network) Type |

Pulse Input or Stored Data (Network Compatible) Type |

Safety |

Built-in Protective Functions / Safe Torque Off (STO) |

Built-in Protective Functions |

Built-in Protective Functions |

Stepper Motor Product Comparison

Product Series |

|||

|

|

|

|

|

Features |

Closed Loop, |

Closed Loop, |

High-Efficiency |

Basic Step Angle |

0.36° |

0.36° |

0.72° |

Driver Power Input |

AC or DC |

AC or DC |

AC |

Frame Sizes |

0.79 in. (20 mm) |

1.10 in. (28 mm) |

1.65 in. (42 mm) |

Available Options |

Geared Type |

Geared Type |

Geared Type |

Max. Holding Torque |

2.8 oz-in up to 752 lb-in |

42 oz-in up to 320 lb-in |

19.8 oz-in up to 460 lb-in |

0.02 N·m up to 85 N·m |

0.3 N·m up to 37 N·m |

0.14 N·m up to 52 N·m |

|

Learn More |