Case Study - Industrial Robot and Conveyor Automation Demo

For this case study, our application engineering group combined 2 OVR Series articulated robots and MRC robot controllers with our BLH Series brushless DC motors to run two conveyors to demonstrate a working example of the warehouse work roles; Picking, Packing, Shipping, Receiving, Unpacking and Stocking.

- Intro

- Vision System

- 5-Axis Robot

- Conveyor System

- Pallet Packing

- Electric Gripper

- 4-Axis Robot

- Electric Pump

- MRC Software

- Support

5-Axis Articulated Robot

Pick and Place Robot with Electric Gripper

In this demo, two different pick and place methods are shared; an EH series electric gripper/robotic gripper 2-finger type and a Schmalz puematic suction cup.

The OVR 5-Axis articulated robot with MRCU robot controller can support two end effectors.

In this case the EH4 electrical gripper is used as the end effector 1 on the wrist rotation axis, R-axis.

The OVR 5-Axis articulated robot end effector mounting complies with ISO 9409-1-31.5-4-M5 standards.

The Robot flange adapter P3F2 is used to mount the EH4-AZAKH as the end effector.

When the TCP of the OVR 5-Axis articulated robot is located to the target position, the MRC robot controller controls the gripper to grab the target.

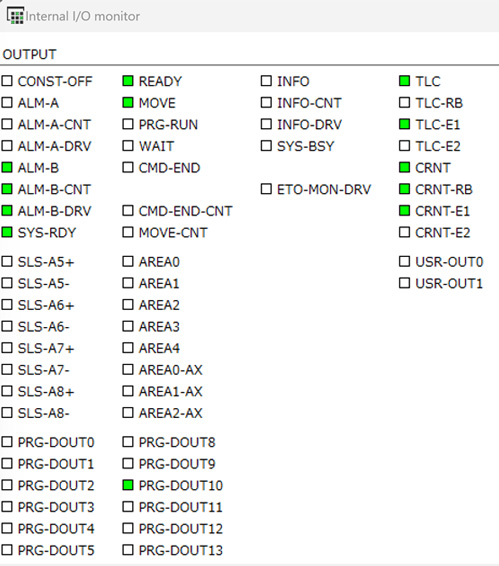

When EH4 gripper successfully grabs the target, the push-motion is activated to maintain the holding load. Simultaneously, the EH4 gripper output TLC output signal to confirm the target has been grabbed successfully. If the EH4 gripper unsuccessfully grab the target, the TLC output will not output.

In this demo, MRC robot controller is programmed to stop the operation if TLC is not output while it is supposed to output.

Input/Output Monitor

Mounted on THK Linear Slide

OVR 5-Axis articulated robot has a reach range 350mm due to the compactness.

When short reach motions are required in wide work field, DC input compact OVR robots are suitable to be mounted on external actuators or AGVs to increase the work range.

In this case, the OVR 5-axis articulated robot is mounted to a THK linear slide using our AZ Series step-servo hybrid motor to allow it to move and perform all necessary work.

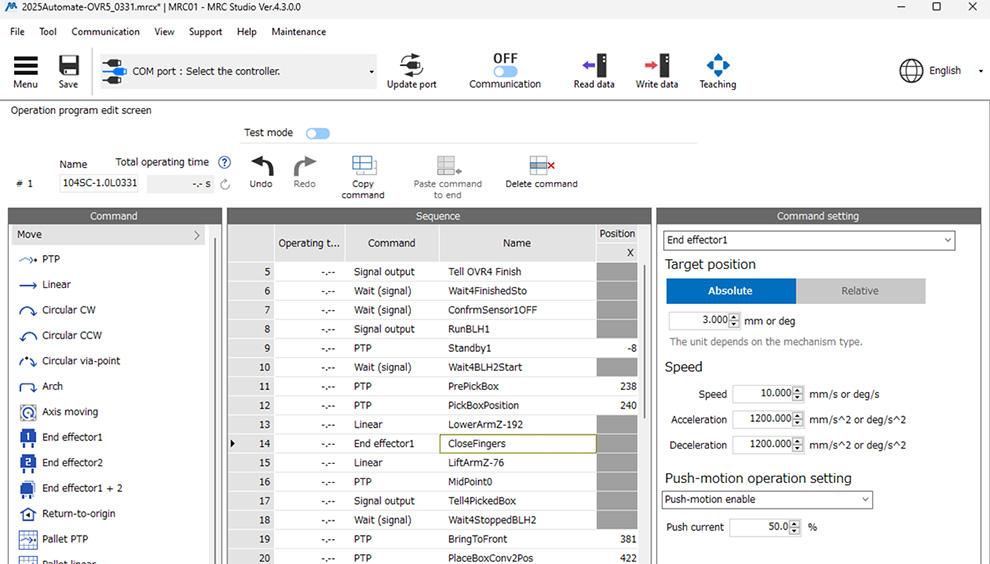

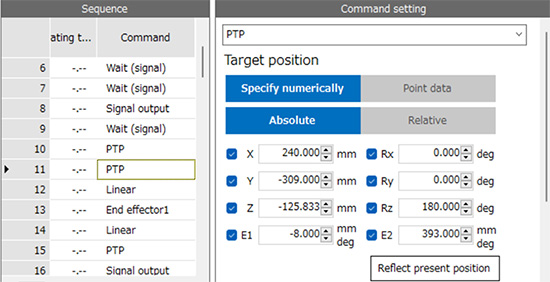

Controlling the End Effector

The End effector1 command to close the electrical fingers to 3mm position from the previous position of 8mm. The gripper will apply push force to hold the car with 50% of its gripping force. This makes the gripping motion.

Composite Command

Learn More About The Products Used

OVR Series Articulated Robots

|

MRCU Integrated Robot Controller & Drivers

|

MRC Studio Robot Software

|

EH Series Gripper

|

AZ Series Step-Servo Motors

|

THK Linear Slides

|

BLH Series Brushless DC Motors

|

Rotary Encoders

|