Case Study - Industrial Robot and Conveyor Automation Demo

For this case study, our application engineering group combined 2 OVR Series articulated robots and MRC robot controllers with our BLH Series brushless DC motors to run two conveyors to demonstrate a working example of the warehouse work roles; Picking, Packing, Shipping, Receiving, Unpacking and Stocking.

- Intro

- Vision System

- 5-Axis Robot

- Conveyor System

- Pallet Packing

- Electric Gripper

- 4-Axis Robot

- Electric Pump

- MRC Software

- Support

Pallet Packing

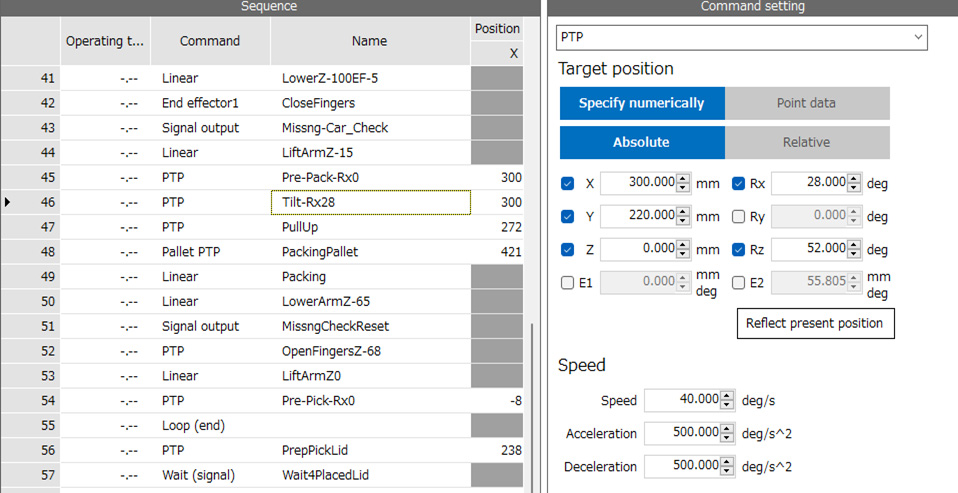

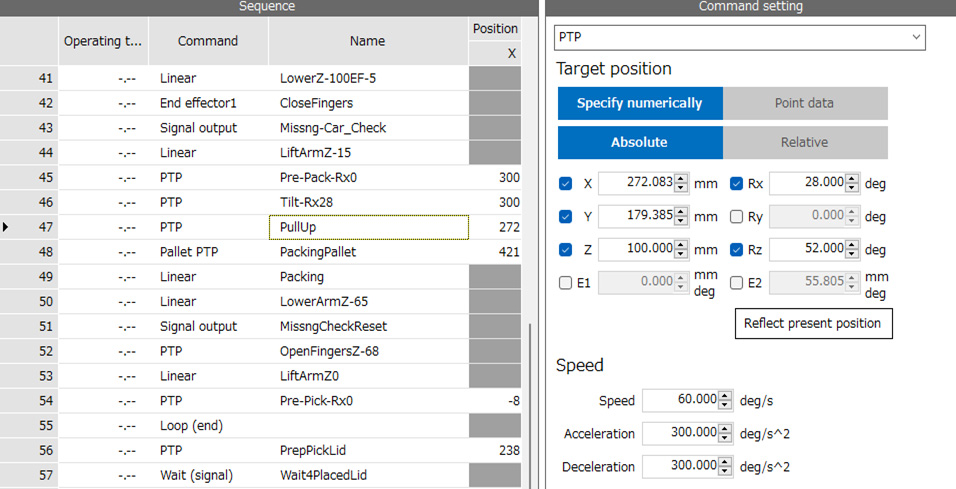

5-Axis Articulated Robot Control

OVR 5-Axis articulated robot is packing cars in the box with even space between cars.

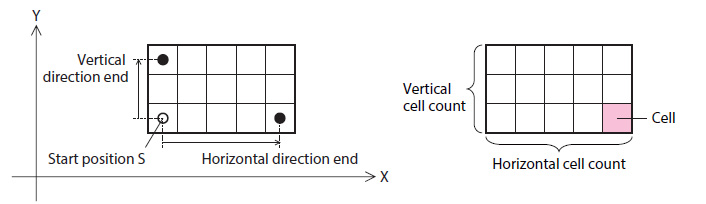

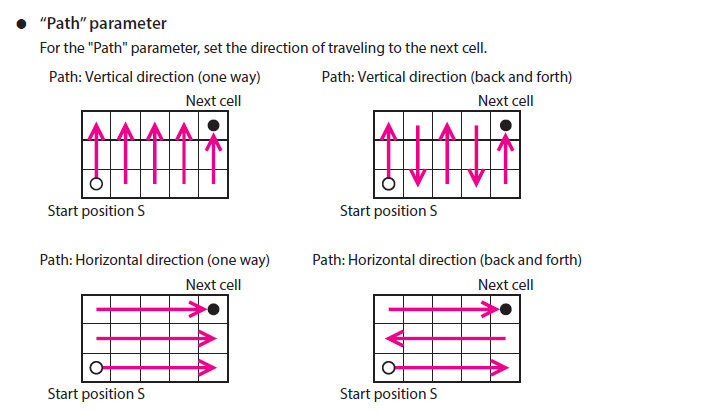

This series of motions can be programmed easily using the Pallet command in the MRC Studio Software.

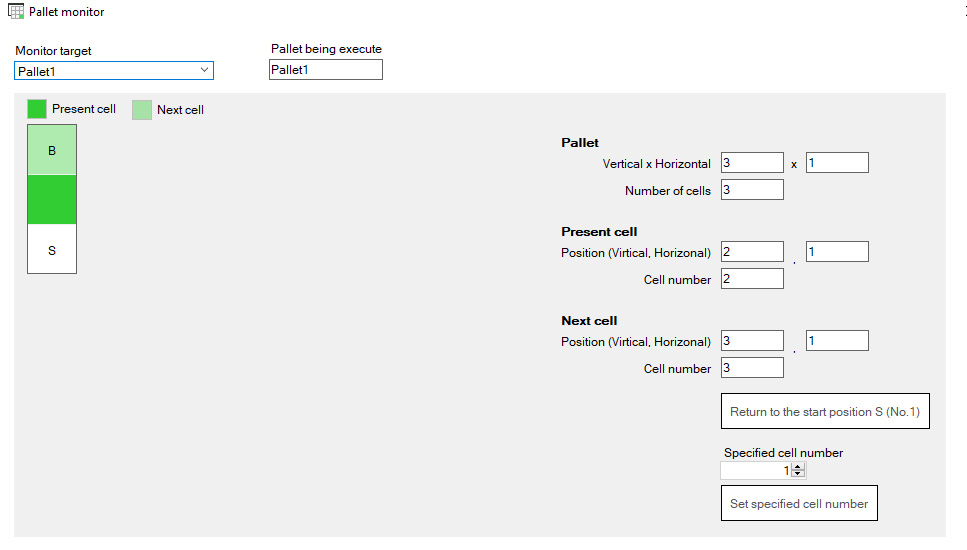

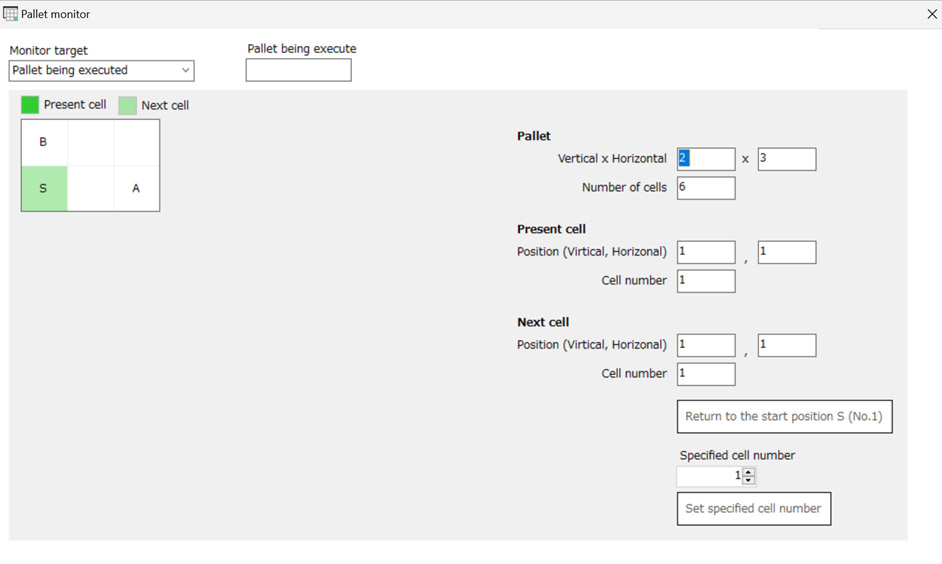

In this application, it uses a 1 column x 3 rows pallet setting.

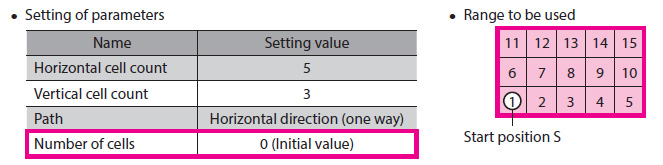

The MRC software allows setting 6 different pallets in X, Y and Z coordinates per program.

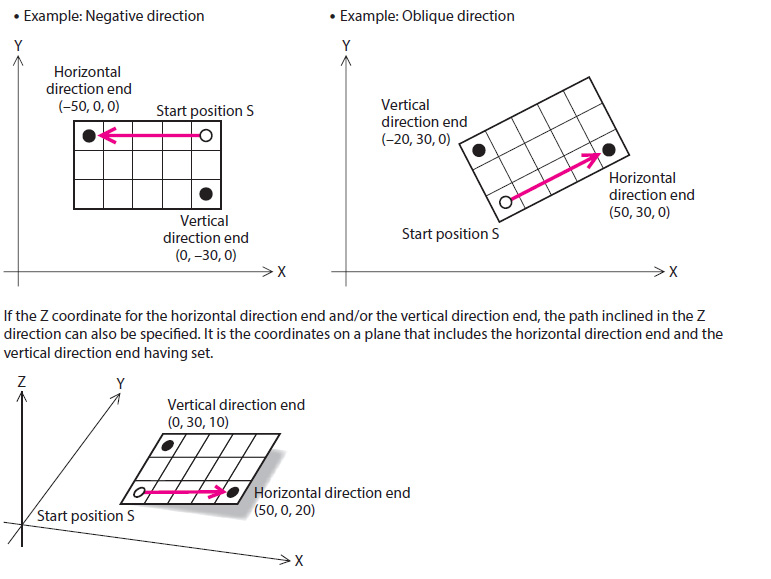

The number of cells to execute and path can be programmed as well.

The MRC software has 3 different types of pallet motions, Pallet PTP, Pallet linear and Pallet arch. This simplifies the sequence programming required.

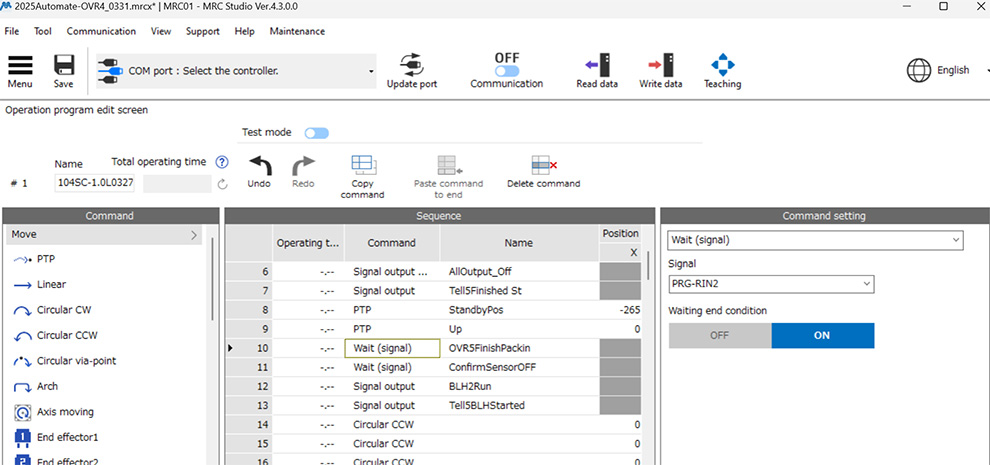

Wait signal

The OVR 4-Axis articulated robot holds the following commands until it receives the signal PRG-RIN2 turns on from OVR5.

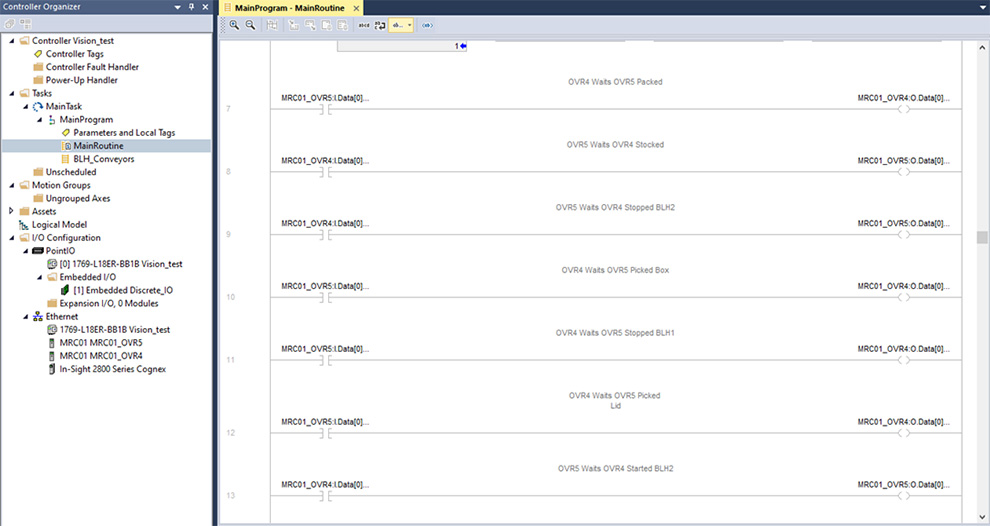

PLC Controller

MRC Studio

Pallet Monitor

Pallet Functions

Learn More About The Products Used

OVR Series Articulated Robots

|

MRCU Integrated Robot Controller & Drivers

|

MRC Studio Robot Software

|

EH Series Gripper

|

AZ Series Step-Servo Motors

|

THK Linear Slides

|

BLH Series Brushless DC Motors

|

Rotary Encoders

|