Case Study - Industrial Robot and Conveyor Automation Demo

For this case study, our application engineering group combined 2 OVR Series articulated robots and MRC robot controllers with our BLH Series brushless DC motors to run two conveyors to demonstrate a working example of the warehouse work roles; Picking, Packing, Shipping, Receiving, Unpacking and Stocking.

- Intro

- Vision System

- 5-Axis Robot

- Conveyor System

- Pallet Packing

- Electric Gripper

- 4-Axis Robot

- Electric Pump

- MRC Software

- Support

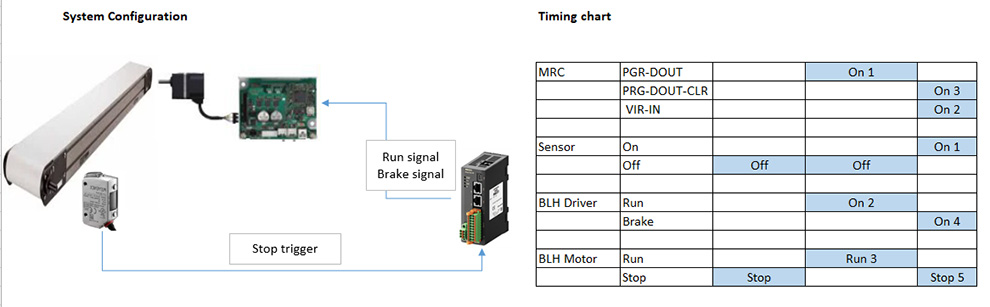

Conveyor System

Brushless DC Motors

The BLH series brushless DC motor is driving the conveyors.

The RUN/BRAKE input of the BLH driver is controlled directly by the MRC controller.

When the Signal Out (PRG-DOUT) command in the program of the MRC is executed, the BLH driver runs the BLH motor.

The sensor output is connected to one of the Direct inputs of the MRC controller.

When the sensor is triggered, the assigned VIR-IN is turned ON.

The MRC controller can program different actions when VIR-IN is ON. In this case, the PRG-DOUT-CLR (program output clear) output is assigned.

Therefore, the RUN/BRAKE input is turned OFF when sensor triggers, stopping the conveyor.

In this application, to provide extra safety, the STOP input is also assigned to the PRG-DOUT-CLR output using the virtual input VIR-IN.

BLH Series BLDC Conveyor Control

Timing Chart

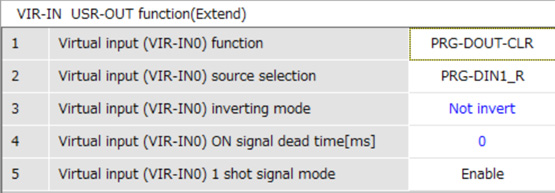

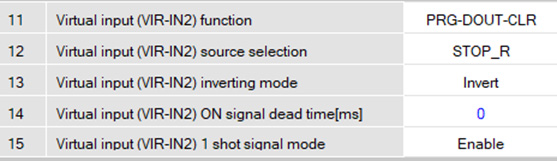

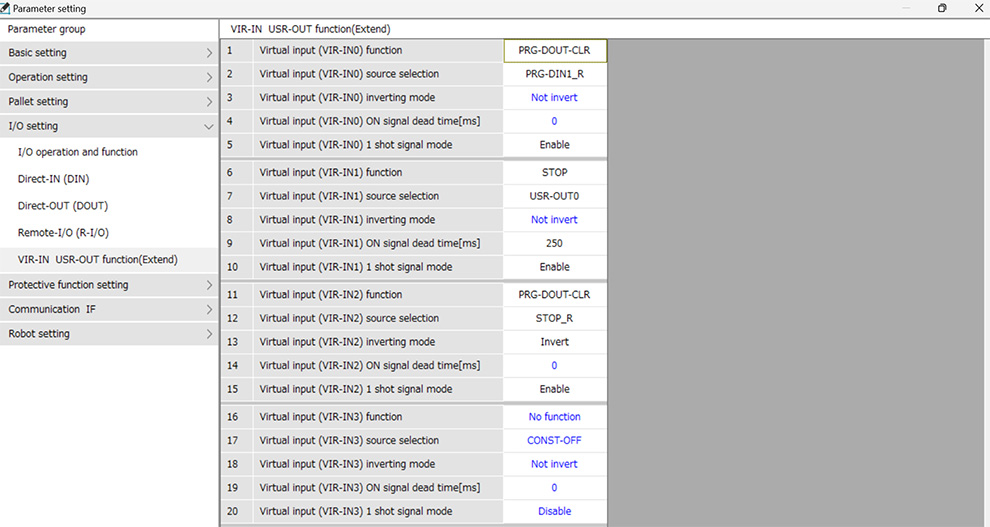

When Direct Input1 is ON, PRG-DOUT-CLR is ON.

This means turn off the PRG-DOUT1

When MRC detects the STOP input is turned OFF (Normal close logic), it turns PRG-DOUT-CLR output ON and stop the conveyor motor.

Parameter screen

Rotary Encoder

A Rotary Encoder is mounted on a wheel to measure the actual conveyor belt movement.

The Rotary Encoder offers twin shaft style, solid shaft and hollow shaft to make easily on the drive shaft directly or using a wheel like this demonstration.

Mounting on drive shaft saves space while mounting to a wheel on the belt will measure the actual belt speed even if slippage occurred.

Three signal output styles are available; Voltage, Open-Collector and Differential (Line driver).

Voltage style is conveniete when an external voltage source is not available since the voltage of output is internally provided.

Open-Collector is more common and can accept wider external voltage range 5v to 24v of source.

Differential (Line driver) is useful when the environment has electrical noise.

Learn More About The Products Used

OVR Series Articulated Robots

|

MRCU Integrated Robot Controller & Drivers

|

MRC Studio Robot Software

|

EH Series Gripper

|

AZ Series Step-Servo Motors

|

THK Linear Slides

|

BLH Series Brushless DC Motors

|

Rotary Encoders

|