Case Study - Industrial Robot and Conveyor Automation Demo

For this case study, our application engineering group combined 2 OVR Series articulated robots and MRC robot controllers with our BLH Series brushless DC motors to run two conveyors to demonstrate a working example of the warehouse work roles; Picking, Packing, Shipping, Receiving, Unpacking and Stocking.

- Intro

- Vision System

- 5-Axis Robot

- Conveyor System

- Pallet Packing

- Electric Gripper

- 4-Axis Robot

- Electric Pump

- MRC Software

- Support

Vision System

Using a Vision System for 5-Axis Robot

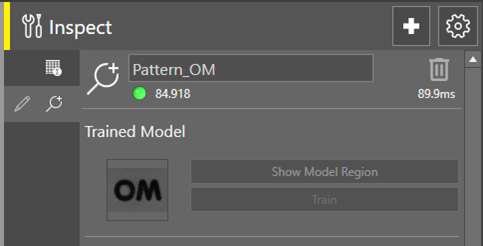

When the targets are located in the picking area, the MRC robot controller sends a Remote Output command "PRG-ROUT0" to the Cognex In-Sight 2802 series vision system to trigger the image.

The command is transferred through Ethernet IP communication using the PLC, Allen Bradley Compact Logix 1769 series.

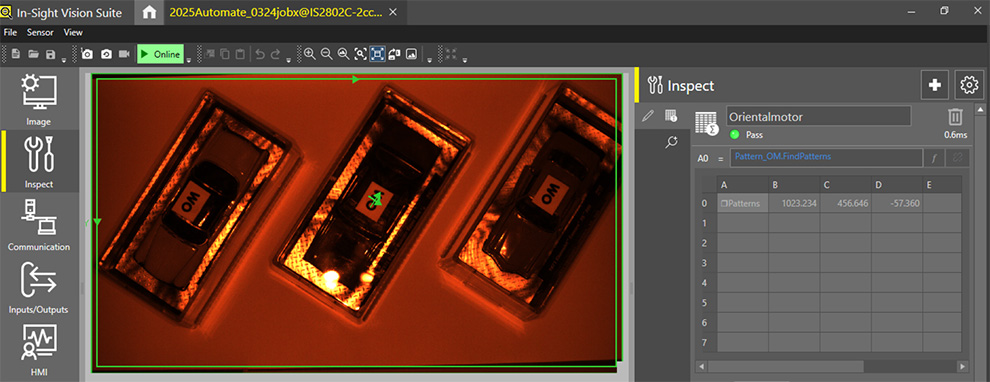

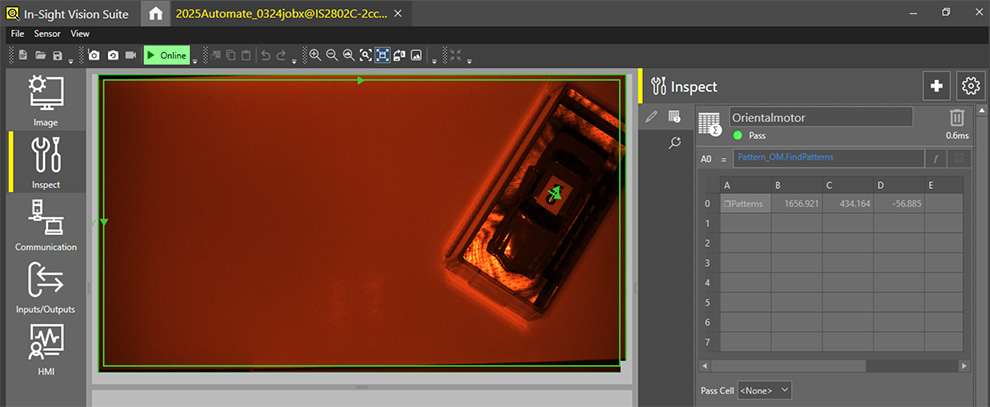

When the command is transferred from Allen Bradley Compact Logix PLC, the Cognex In-Sight 2802 vision system captures the target images. Cognex In-Sight 2802 Vision Suite software compares the captured image with the preregistered image, and locates the most recognized image's position in terms of vision coordinates.

Then, the MRC robot controller sends another Remote Output command "PRG-ROUT1" to acquire the captured coordinate data from the Cognex In-Sight 2802 vision system to the MRC.

Receiving the vision coordinate X, Y, Angle data, the MRC converts the data to the equivalent Robot coordinate data in reference to its TCP (Tool Center Point) and moves the arm to the position.

The MRC robot controller is built-in with a vision coordinate and robot coordinate calibration function. This vision and robot coordinates calibration function is a semi-automatic process. Having this function allows any vision system that has X, Y, and Angle output with Ethernet IP communication to be used. This vision and robot coordinate calibration function reduces the cost of the vision system.

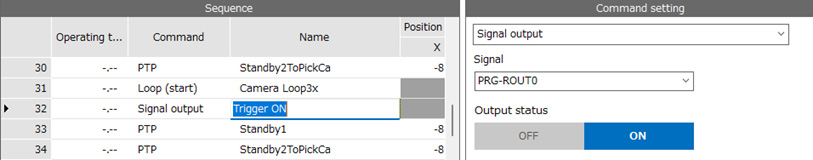

Setting Vision Trigger with MRC Studio Software

Command Vision trigger ON using one of the Remote outputs "PRG-ROUT0"

Command the Acquire the vision coordinate data ON using one of the Remote outputs "PRG-OUT1"

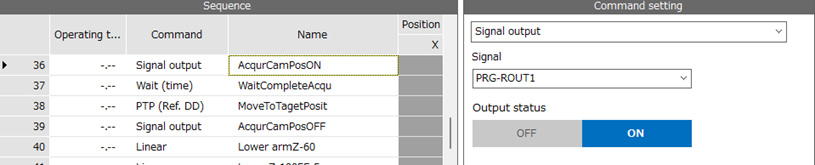

Input/Output Monitor:

"PRG-ROUT0" will be turned ON

"PRG-ROUT1" will be turned ON

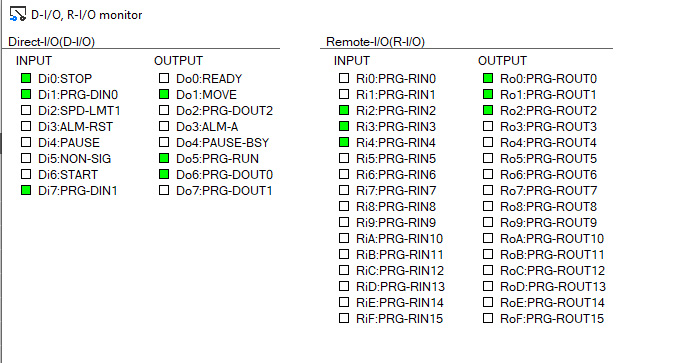

Vision System

Registered Logo = Target Object

Vision System Coordinates

Capture the position of the target object in Vision coordinate, X, Y, Angle

Learn More About The Products Used

OVR Series Articulated Robots

|

MRCU Integrated Robot Controller & Drivers

|

MRC Studio Robot Software

|

EH Series Gripper

|

AZ Series Step-Servo Motors

|

THK Linear Slides

|

BLH Series Brushless DC Motors

|

Rotary Encoders

|