Case Study - Industrial Robot and Conveyor Automation Demo

For this case study, our application engineering group combined 2 OVR Series articulated robots and MRC robot controllers with our BLH Series brushless DC motors to run two conveyors to demonstrate a working example of the warehouse work roles; Picking, Packing, Shipping, Receiving, Unpacking and Stocking.

- Intro

- Vision System

- 5-Axis Robot

- Conveyor System

- Pallet Packing

- Electric Gripper

- 4-Axis Robot

- Electric Pump

- MRC Software

- Support

Electric Gripper

EH Series Electric Gripper

The EH gripper can grab object and determine if the object is grabbed or the size is correct.

In this application it is programmed to detect the existence of the object.

When the EH gripper successfully grabs a car, the program will continue to packing.

However, if it did not grab or missed during the packing sequence, it can be programmed to stop the program.

You can select different actions such as output signal to notify when an object is missed.

In this application it is programmed to stop executing program so it does not let shipping with missing a car (mis shipping orders).

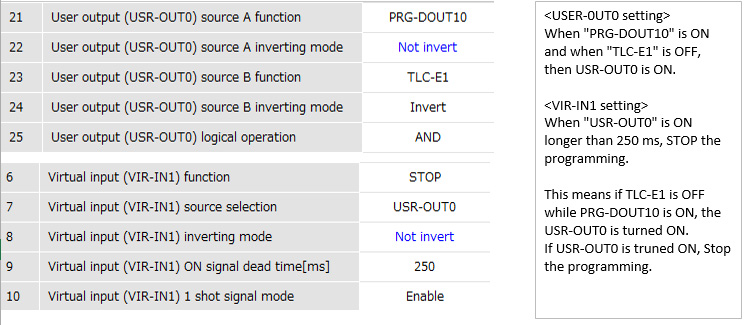

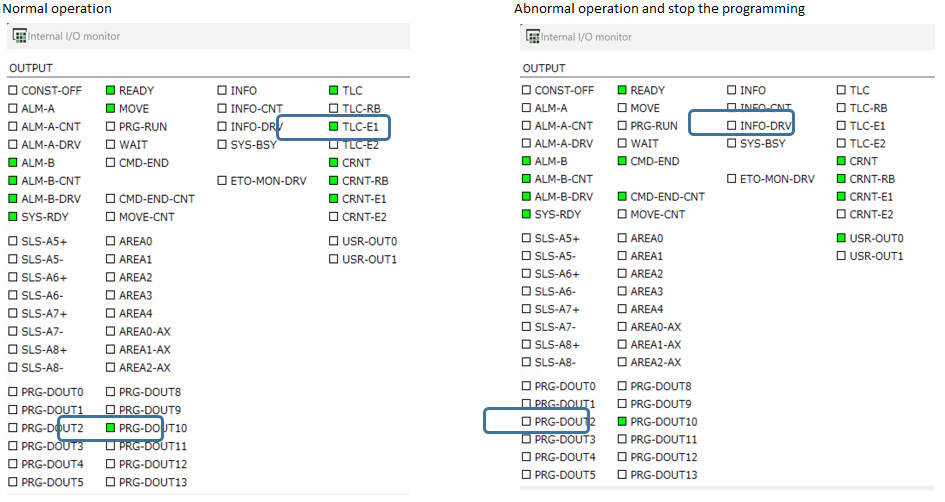

The combination of USER OUTPUT and VIRTUAL OUTPUT functions of MRC is used.

In normal operation the TLC-E1 output is turned ON when the EH gripper grabbed the car.

<USER-0UT0 setting> When "PRG-DOUT10" is ON and when "TLC-E1" is OFF, then USR-OUT0 is ON. <VIR-IN1 setting>

When "USR-OUT0" is ON longer than 250 ms, STOP the programming.

This means if TLC-E1 is OFF while PRG-DOUT10 is ON, the USR-OUT0 is turned ON. If USR-OUT0 is turned ON, Stop the programming.

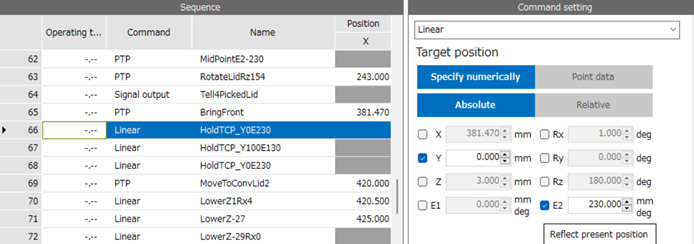

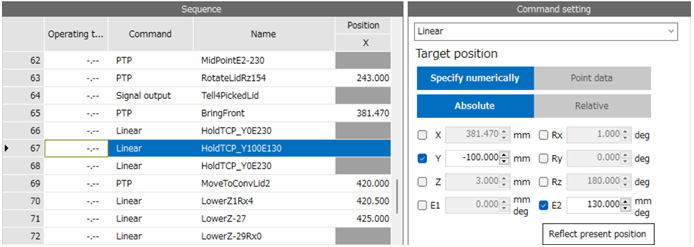

Having the second end effector in Y coordinate allows maintain the TCP position while the body of robot moves.

In this application, it is just a fun demonstration.

However, this movement will be useful if robot arm or body is blocking other tool to access the work, such as machining or inspecting.

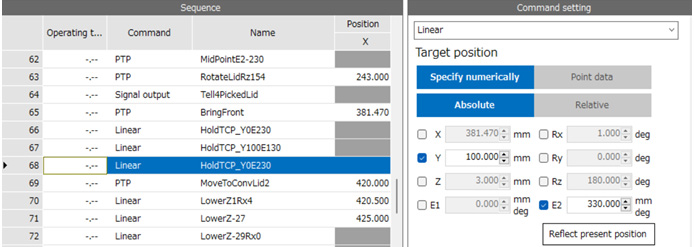

Sequence Examples

Learn More About The Products Used

OVR Series Articulated Robots

|

MRCU Integrated Robot Controller & Drivers

|

MRC Studio Robot Software

|

EH Series Gripper

|

AZ Series Step-Servo Motors

|

THK Linear Slides

|

BLH Series Brushless DC Motors

|

Rotary Encoders

|