Product & Training Videos

Oriental Motor’s video content covers key engineering topics including stepper motors, servo motors, brushless DC (BLDC) motors, AC motors, electric actuators, industrial robots, axial and centrifugal fans, motion control software, and PLC integration. Learn how to select, configure, and apply motion control products across real-world applications. Our video collection includes detailed product demos, application examples, product details and how-to guides.

On-demand webinars and technical training videos are also available to help you further your understanding and stay up to date with the latest motion control technologies by Oriental Motor. Start learning now and streamline your next automation project with Oriental Motor.

Applications

Modular Automation – Visual Inspection

Module 3 of 5 highlights workpiece visual inspection using Oriental Motor’s modular automation products. A compact 3-axis SCARA robot built with a DGII Series hollow rotary actuator enables efficient cable routing. The system features an AZ-equipped rack and pinion Z-axis, an EH Series electric gripper for tight spaces, and a DR Series electric cylinder for lightweight, space-saving performance.

1:05 minutes

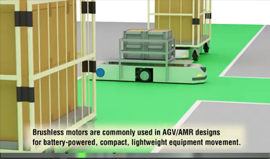

Modular Automation – AGV/AMR

See how Oriental Motor products enable AGV/AMR mobility in this 5th module of our automation series. Featuring the BLV Series R Type for smooth, battery-powered motion and compact AZ Series mini Drivers for precise, space-saving control—ideal for high-throughput workpiece assembly.

01:02 minutes

Modular Automation – Workpiece Disassembly

In module 4 of 5, see how Oriental Motor products enable high-speed workpiece disassembly. A parallel link robot powered by harmonic geared motors and the MRC01 Controller delivers agile motion. Compact AZ Series, EZS slides, and BMU Series motors ensure precise, space-saving, and energy-efficient operation.

01:03 minutes

Modular Automation – Workpiece Assembly + Press Fitting

In module 2 of 5, watch how Oriental Motor products enable efficient workpiece assembly and press fitting. The MRC01 Controller simplifies programming with palletizing, while EZS Series slides form a rigid cantilever setup. A DRS2 electric cylinder ensures precise press fitting, paired with an EH Series gripper for tight-space handling.

01:01 minutes

Discover the Benefits of αSTEP AZ Series in Equipment with Multiple Processes

Discover the benefits of adopting the αSTEP AZ Series for loader/unloaders, transfer processes and machining processes in equipment that handle multiple processes.

01:14 minutes

Manual Labor vs. SCARA Robot Automated Pin Press Process

See how an in-house SCARA robot built with AZ Series stepper motors automates pin assembly with a compact footprint. For help building smaller, lighter robots, ask us about our modular automation products.

02:22 minutes

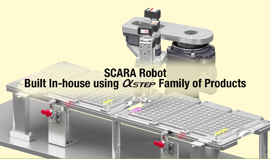

How to Assemble a SCARA Robot

This video shows how to assemble a SCARA robot using Oriental Motor's Alpha Step AZ Series family products.

00:08 seconds

Transport Robot Used in a Modular Automation Factory

Various Oriental Motor products can be used to automate different motion axes of a transport robot used in a modular automation factory, such as the wheel drive, conveying, indexing, lifting, or arm joint axes.

02:11 minutes

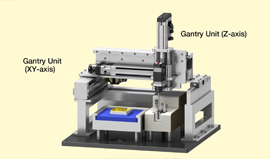

Modular Automation Example - Cartesian Robot

Cartesian robots can be used to apply the adhesive coating and can be manufactured in-house with Oriental Motor products such as EZS Series electric slide, EAC Series electric cylinder, DR Series compact electric cylinder, and the robot controller MRC01.

01:50 minute

Lifting Equipment

Lifting equipment can be used to transfer parts and can be manufactured in-house with Oriental Motor products such as αSTEP AZ Series.

00:45 seconds

SCARA Robot

SCARA robots can be used to tighten screws and can be manufactured in-house with Oriental Motor products such as the DGII Series hollow rotary actuator, αSTEP AZ Series, DR Series compact electric cylinder, and the MRC01 robot controller.

00:52 seconds

Parallel Link Robot

Parallel link robots can be used to transfer parts and can be manufactured in-house with Oriental Motor products such as αSTEP AZ Series, L Series Rack and Pinion System, and the BLV Series R Type brushless motor.

00:43 seconds

Transport Robot

Transport robots can be used to transfer parts and can be manufactured with Oriental Motor products such as BLV Series R Type compact, lightweight, and high-power brushless motors.

00:42 seconds

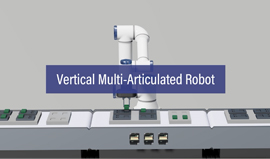

Vertical Multi-Articulated Robot

Vertical multi-articulated robots can be used to transfer and assemble parts and can be manufactured in-house with Oriental Motor products such as αSTEP AZ Series, EH Series Grippers, and the MRC01 Robot Controller.

01:43 minutes

SCARA Robot Demo

This video showcases a custom 5-axis SCARA robot built with Oriental Motor’s hollow rotary actuators, harmonic geared stepper motor, compact cylinder, and gripper—all using the same drivers and battery-free absolute encoder.

01:28 minutes

Guide to Carbon Neutrality

Carbon neutrality is the balancing act between the emission and absorption of CO² and other greenhouse gases, which is closely related to the burning of fossil fuels for electricity generation. Oriental Motor offers tips for saving energy and resources anywhere automation is required.

04:32 minutes

Introduction to Modular Automation

Solutions for limitless automation. Introducing modular automation compatible products from Oriental Motor.

01:55 minutes

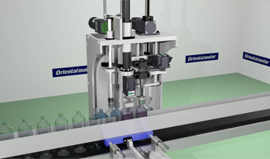

Screw Tightening Equipment with Example

This screw tightening equipment application example demonstrates how various Oriental Motor drivers and motor products are used in actual manufacturing facilities.

01:22 minutes

Load Transportation System Example

This video demonstrates the different capabilities of Oriental Motor's motion control products and how they work together in an actual manufacturing facility.

01:22 minutes

Work Processing Equipment with Example

This right-angle robot / elevation swivel unit utilizes a combination of multiple Oriental Motor motion control products working together to handle continuous work with a moving load.

01:44 minutes

Parts Handling with Product Examples

Here is a system designed to move parts of various size using standard drive and motor technology. The system is comprised of several Oriental Motor products. Watch this video to learn how these individual Oriental Motor products work together to move the system.

01:28 minutes

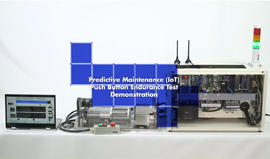

Predictive Maintenance Using IoT (Internet of Things)

This video shows how the AZ Series, paired with an IoT setup, monitors position changes to detect early signs of failure. By visualizing temperature and usage-related shifts, you can assess component health and boost productivity.

02:05 minutes

Stepper Motor Application - CCD Camera Positioning

Stepper motor's precise positioning control enables accurate CCD camera alignment. Ideal for machine vision, inspection, and microscopy applications requiring stable, repeatable movement.

00:07 seconds

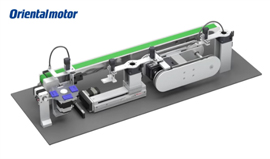

Stepper Motor and Linear Actuator Application - Positioning

Stepper motors provide high torque at low speeds with minimal vibration, making them ideal for quick, short-distance positioning. Servo motors offer smooth operation for large inertial loads and belt mechanisms.

00:19 seconds

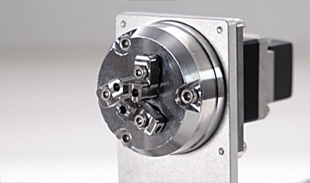

Linear Actuator and Rotary Actuator Multi-Axis Pick and Place Demo

This video demonstrates a pick and place applicationusing three different products: Rotary actuator (DGII Series), compact linear actuator (DRS2 Series) and linear slides (EAS and EZS Series).

00:55 seconds

Electric Motor & Linear Actuator Video - Automation

Designing automated equipment requires considering layout, environment, maintenance, and wiring, making motor selection and documentation time-consuming. Using linear and rotary actuators can simplify this process.

02:32 minutes

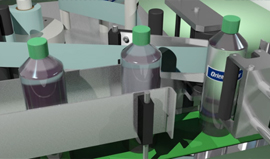

Electric AC Motor Video - Labeling

Oriental Motor offers AC motors for constant speed and AC or brushless DC systems for variable speed, higher speeds, and compact, high-torque needs in labeling and conveyors.

00:31 seconds

Electric AC Motor and Cooling Fan Video - Cooling on a Conveyor

AC induction motors are ideal for conveyor systems that operate continuously in one direction. Cooling fans can be utilized to aid in the drying process for manufactured parts.

01:12 minutes

AC Gear Motor Video - Conveyor Applications

The hollow shaft right-angle gearhead saves space and eliminates couplings. Oriental Motor offers various options.

01:08 minutes

AC Gear Motor Video - Packaging

Oriental Motor provides AC motors for constant speed and AC or brushless DC systems for variable speed, higher speeds, and compact, high-torque needs in packaging and conveyors.

01:14 minutes

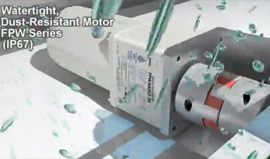

IP67 Electric AC Motor Video - Washdown Conveyor

The FPW Series AC motors are IP67-rated, watertight, dust-resistant, UL recognized, and ideal for wet environments.

00:30 seconds

Electric AC Motor Video - Injection Applications

AC motors include single-phase motors, which require a capacitor, and three-phase motors, which don't.

02:21 minutes

Linear Actuator Application - XYZ Positioning

Designing automated equipment involves factors like layout, environment, maintenance, and wiring, requiring significant time for motor and component selection. Using linear actuators can reduce this time and provide added benefits.

00:48 seconds

Stepper Motors

5-Phase CVD Series Fully Closed-Loop Stepper Motor Driver

The CVD Series driver uses a closed-loop control system with an external sensor for precise positioning. If the desired position isn't reached, the system transitions from open-loop to closed-loop control for accurate position correction.

01:18 minutes

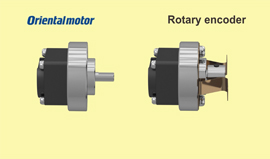

PKP Series Encoder Type Stepper Motors

Position information from the encoder enables position monitoring and detection of displacement on the stepper motor. Learn how our compact encoder operates with usage examples.

01:14 minutes

PKP Series Stepper Motor Flat Type

The flat PKP Series stepper motor can be installed in a narrow space, saving space as a result. Compared to a motor of equivalent torque, the motor length is shorter by 15 mm.

01:16 minutes

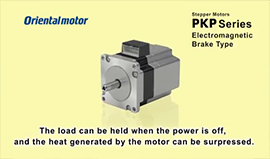

PKP Series Electromagnetic Brake Type Stepper Motors

The electromagnetic brake is located in the back and operates separately from the stepper motor. When the power is cut off, the electromagnetic brake holds the load in position. Learn how our power off-activated electromagnetic brake stepper motor works and the applications that can benefit from it.

01:43 minutes

PKP Series High Resolution Type

Microstep performance comparison of PKP Series high resolution type.

01:28 minutes

PKP Series High Resolution Type Stepper Motors

High resolution type stepper motors provide high accuracy positioning that is effective for friction loads. Learn the difference between standard and high resolution type in this video, and how high resolution type motors are utilized in various applications.

02:13 minutes

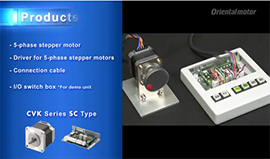

CVK Series SC Type Stepper Motor Speed Control System

The CVK Series SC speed control system combines a stepper motor, driver, and programmable controller. Speed, acceleration, deceleration, and current are set via driver switches, with easy control through the FWD (RVS) input.

01:23 minutes

Features of the CVD 2-Phase Bipolar Stepper Motor Drivers

The CVD driver offers superior performance and value and is ideal for OEM or single axis machines. The CVD is available as a driver only or part of a complete package.

01:35 minutes

Wiring for Power Supply (AC Power input type)

The AZ Series AC input driver requires wiring for both AC and DC power supplies. This video explains how to properly wire both power type.

03:03 minutes

Hybrid Step-Servo

Simplify Precision and Reliability With Products from the Same Family

Oriental Motor's αSTEP Hybrid Step-Servo motors, actuators, and OVR small industrial robots are equipped with our battery-free absolute encoders, and their unified control architecture can simplify precision and reliability where it matters most, such as handling sensitive materials like wafers for the semiconductor industry.

00:58 seconds

How to Assemble an AZ Series Integrated Step-Servo Motor-Driver Solution

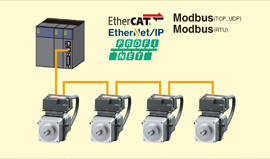

The AZ Series offers an integrated stepper motor and driver solution, with the mini Driver supporting EtherCAT, EtherNET/IP, PROFINET, Modbus, and other field protocols for flexible design.

01:00 minutes

AZ Series Gripper Demo (Load Detection)

Gripper with load detection powered by Oriental Motor's AlphaStep Hybrid Control Systems AZ Series.

00:58 seconds

AZ Series Gripper Demo (Variable Speed)

Gripper with variable speed powered by Oriental Motor's AlphaStep Hybrid Control Systems AZ Series.

00:54 seconds

AZ Series Gripper Demo (Squeezing)

Gripper demonstrating squeezing capability, powered by Oriental Motor's AlphaStep Hybrid Control Systems AZ Series.

00:56 seconds

AZ Series with Rack and Pinion

The AZ Series is suitable for rack and pinon mechanisms, such as a lift.

01:09 minutes

AZ Series Stepper Motor Mechanical Absolute Encoder Restart Demo

AZ Series Closed Loop Stepper Motor video example of restarting after an emergency power shut down or outage using stored data FLEX driver type.

00:37 seconds

AZ Series Stepper Motors Easy Home Setting

How to set the Home position with the all new AZ Series stepper motor with the newly developed absolute mechanical encoder.

00:54 seconds

AZ Series Stepper Motor Products with Mechanical Absolute Encoder

The AZ Series stepper motor offers high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy.

03:32 minutes

Brushless DC Motors

Easily downsize your 1 HP AC motor with a 1 HP BLDC motor and upgrade your performance

Our 750 W (1 HP) brushless motors and gearmotors are compact, efficient, closed-loop solutions that work with popular VFDs like ABB, Fuji, Mitsubishi, and Rockwell. Easily downsize your machine footprint and boost performance without replacing your existing VFD.

01:51 minutes

Enhancing the Efficiency of Transport Conveyors

Brushless motors are smaller, lighter, and more efficient than AC induction motors, enhancing transport conveyors by saving space, reducing weight, conserving energy, and ensuring speed consistency. With high IP ratings and optional H1 food-grade grease, they're ideal for food machinery.

02:09 minutes

BLS Series - Simple, Compact, and Cost-Effective

Looking to maximize space and reduce operating expenses? The compact and efficient BLS Series brushless motors and drivers are easier to install in tight spaces and significantly reduce power consumption when compared to AC motors.

00:55 seconds

BLV Series R Type Product Introduction

Brushless motors, like the BLV Series R Type, are ideal for AGV/AMR designs due to their compact, lightweight, and maintenance-free nature. They offer smooth performance, positioning, and support common communication protocols. Watch this video to learn more about this new Oriental Motor product and its benefits for your next project.

01:32 minutes

BMU Series Brushless DC Motor Wiring

The BMU Series brushless DC motor and driver offer easy setup with plug-in cables and screw-less connectors—no soldering needed. Just switch to "RUN" to start, "STAND-BY" to stop, and use the driver switch to change rotation direction.

00:34 seconds

Brushless DC Motor Speed Control Product Demo

Oriental Motor's BLDC motors offer up to 970 lb-in of torque in a compact design, with power from 15W to 400W. They deliver flat torque across speeds and come with gear options, brakes, and stable lead times.

00:30 seconds

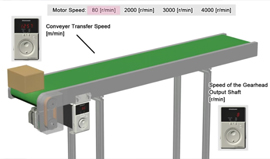

Brushless DC Motor Video - Conveyor Speed Control

The BMU Series offers a speed range of 80–4000 r/min, allowing flexible gear ratios and torque. It's a great alternative to servo, brushed, or AC inverter-driven motors.

01:04 minutes

Brushless DC Motor Video - Conveyor

The Oriental Motor Brushless DC Motor and Speed Controller enable easy speed control and multiple speed settings in an inspection machine, providing flat torque across a wide range.

00:28 seconds

BMU Series BLDC Motor Features and Benefits

The BMU Series combines a compact, high-efficiency BLDC motor with an easy-to-use speed controller, featuring the latest technology for optimal performance.

02:37 minutes

Modular Automation – Workpiece Transfer + Alignment

Module 1 of 5 features workpiece transfer and alignment using Oriental Motor’s modular automation products. A custom AZ Series vertical articulated robot arm handles transfers, while the DGII Series rotary actuator supports cable routing and high-load stability.

01:04 minutes

BLE2 Brushless DC Motor Alarm Output and Torque Limiting

Alarm output and torque limiting capabilities with brushless DC motor feedback control of the BLE2 Series brushless DC motor and driver packages.

02:03 minutes

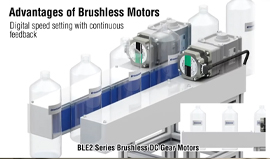

The New Standard of Speed Control - Brushless DC Motors

Brushless DC motors use feedback control for accurate speed control. Being compact, lightweight and high powered makes it a versatile choice for all types of application.

01:05 minutes

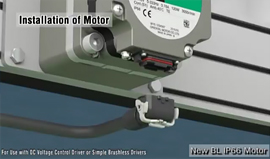

New Brushless DC Motor Connector

The new connector allows screw-free motor-to-driver connection with a lock lever. The motor features IP66 protection with internal gaskets and O-rings for water and dust resistance.

01:11 minutes

BLE2 vs. BMU Series Brushless DC Motor Speed Control Systems

The BLE2 and BMU Series brushless DC motor speed control systems both use the same motor. The underlying differences are in the drivers. Here, our Engineering Manager, Bryan, demonstrates the key differences between the two unique speed control systems.

09:57 minutes

Speed Regulation Comparison

3-Phase induction AC motor vs. BLE2 Series brushless DC motor.

00:30 seconds

Brushless DC Motor Video - Speed Synchronization

This video showcases two BMU Series brushless DC motors operating in a dual-axis synchronous setup, precisely regulating conveyor belt speed within ±0.2%. Ideal for applications requiring consistent and synchronized motion, the BMU Series ensures reliable, high-performance speed control.

00:46 seconds

Noise Reduction Demonstration Using a BLH Series Brushless Motor

In this video, we set up a test to demonstrate the noise reduction from a BLH Series brushless motor by using a driver with the advanced sinusoidal drive method (vector control) versus a driver with the basic trapezoidal drive method.

02:51 minutes

Encoders

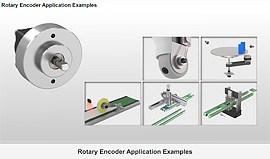

Rotary Encoder Application Examples

By installing a rotary encoder on a mechanism, a preventative maintenance system for that mechanism can be created. Rotary encoders enable precise control in various applications—paper feeds, testers, visual inspection devices, transfer devices, and security camera positioning.

01:44 minutes

New High Resolution Rotary Encoder

A compact, high-resolution magnetic incremental encoder has been released. This new model features a slim, lightweight design with resolutions up to 2000 pulses per revolution.

01:18 minutes

AC Motors

Easily downsize your 1 HP AC motor with a 1 HP BLDC motor and upgrade your performance

Our 750 W (1 HP) brushless motors and gearmotors are compact, efficient, closed-loop solutions that work with popular VFDs like ABB, Fuji, Mitsubishi, and Rockwell. Easily downsize your machine footprint and boost performance without replacing your existing VFD.

01:51 minutes

How to Assemble an AC Motor and Gearhead

This video shows how to properly assemble a motor and gearhead for smooth, optimal performance.

00:43 seconds

DSC Series AC Motor Speed Control Demonstration

This video showcases the DSC Series AC motor speed controller, featuring 4 customizable operating profiles.

01:00 minutes

How-to: Securing an AC motor to a mounting bracket

Learn how to properly install a standard AC motor onto a mounting bracket.

01:07 minutes

KIIS Series KII Series Standard AC Motors

Compact AC standard high efficiency three-phase induction motors.

02:26 minutes

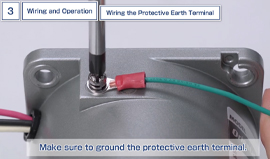

How-to: Wiring and Operation of KII Series Electromagnetic Brake Motor pt. 1

This video demonstrates how to wire and operate a KII Series AC induction motor with electromagnetic brake option.

04:04 minutes

How-to: Wiring and Operation of KII Series Electromagnetic Brake Motor pt. 2

This video demonstrates how to wire and operate a KII Series AC induction motor when controlling the electromagnetic brake independently from the motor.

04:12 minutes

How-to: Wiring and Operation of KII Series AC Reversible Motors

This video demonstrates how to wire and operate a KII Series AC reversible motor.

04:01 minutes

How-to: Wiring and Operation of KII Series AC Induction Motors

This video demonstrates how to wire and operate a KII Series AC induction motor.

03:38 minutes

Wiring and Operation of KIIS Series 3-Phase AC Induction Motors

This video demonstrates how to wire and operate a 3-phase KIIS Series AC induction motor.

04:56 minutes

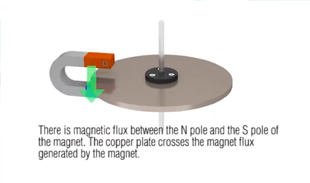

Principle of Arago's Disk

The principle of Arago's disk can be explained by "Fleming's Right Hand Rule" and "Fleming's Left Hand Rule".

01:02 minutes

KIIS Series Three-Phase AC Gear Motors

The KIIS Series is a next-gen, high-efficiency AC motor with robust parallel shaft gears for enhanced performance.

02:41 minutes

Evolution of the New Standard in AC Motors: The KII Series

The KII Series is Oriental Motor's latest compact AC motor, built on decades of innovation since the H Series in 1951.

01:29 minutes

AC Torque Motors Product Demo

Torque motors deliver high starting torque and stable operation across a wide speed range, especially at low speeds or when stalled.

00:48 seconds

IP67 Rated AC Motors Product Demo

FPW Series geared induction motors are IP67-rated, watertight, and dust-resistant, suitable for use in splashing water environments.

00:35 seconds

Linear & Rotary Actuators

Easily Convert Stepper Motors into Linear Actuators

01:47 minutes

How to Assemble a Stepper Motor with a Linear Actuator Attachment

00:54 seconds

Delicate Gripping Demonstration of the EH Series Electric Gripper

The 3-finger αSTEP EH Series electric gripper with AZ Series is perfect for gripping spherical, cylindrical, and deformable workpieces. This video showcases its versatility with various objects of different sizes and materials.

01:30 minutes

EH Series Vertical Transfer Demonstration

One of the features of the 3-finger type αSTEP EH Series electric gripper, AZ Series equipped, is large permissible axial load capacity. This make the EH Series suitable for applications with large workpiece masses.

00:19 seconds

Open and Close Operation of the EH Series Electric Gripper

This video shows how each claw of the 3-finger type αSTEP EH Series electric gripper, AZ Series equipped, opens and closes while rotating.

00:31 seconds

Rotary and Compact Actuators

Motors provide excellent control and are widely used in automation. Oriental Motor offers linear and rotary actuators that combine motors with components like ball screws and belts to convert rotation into motion for various applications.

00:40 seconds

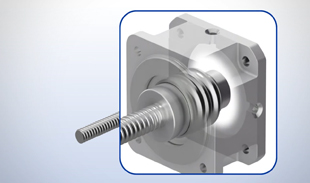

Linear Actuator Demo - Compact Linear Actuators

Compact linear actuators feature a stepper motor integrated with a ball screw. An ideal actuator for pushing and pulling small loads or find-tuning applications. A wide range of frame sizes and features are available.

00:36 seconds

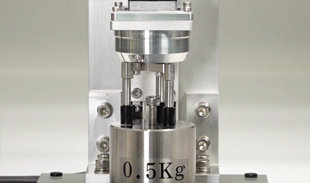

Push Motion Demonstration With DRS2 Linear Actuators and DGII Rotary Actuators

The DRS is a high-precision ball screw integrated with an AZ Series stepper motor and driver for continuous linear motion. The DRS2 Series offers a compact, space-saving design with reduced wiring.

01:14 minutes

Structure and Application Examples of Compact Linear Actuators

Oriental Motor's compact linear actuators perform push-motion operations with adjustable force and timing, ideal for high-precision, micro-positioning, and repetitive closed-loop motion applications.

01:14 minutes

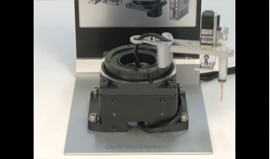

Hollow Rotary Actuator Demo

Oriental Motor’s DG II hollow rotary actuators use precision gears and a unique adjustment mechanism to eliminate backlash, achieving ±15 sec. repeatability and 2 arc min. lost motion—ideal for high-accuracy positioning.

00:39 seconds

Linear Actuator & Rotary Actuator Demo

Oriental Motor has various linear and rotary actuators consisting of a motor assembled with the necessary mechanical components to meet the various needs of automated equipment.

00:40 seconds

Robots

Ceiling Mounted SCARA Robot for Effective Use of Working Space

This video introduces the flexible installation options of the OVR Series 3-axis SCARA robot. By mounting the robot to the ceiling instead of the floor, more of the workspace on the floor can be used effectively.

01:41 minutes

Simplify Precision and Reliability With Products from the Same Family

Oriental Motor's αSTEP Hybrid Step-Servo motors, actuators, and OVR small industrial robots are equipped with our battery-free absolute encoders, and their unified control architecture can simplify precision and reliability where it matters most, such as handling sensitive materials like wafers for the semiconductor industry.

00:58 seconds

3-Axis SCARA Robots (Full 360° Type)

Experience the OVR Series SCARA 3-Axis Robot — precision motion in a compact, flat-profile design. This video showcases its omni-directional movement, versatile installation types, and lightweight, cost-effective build.

00:54 seconds

OVR 3-Axis Horizontal Articulated Robot (SCARA Robot) Motion Comparison - Standard vs Full 360° Type

This is a motion comparison of the compact OVR 3-axis horizontal articulated robots (SCARA robots). It highlights the improved cycle time (takt time) of the Full 360° type SCARA robot compared to the standard SCARA robot (37% reduction).

00:40 seconds

MRC Reality: Free Robot Simulation Tool for Smartphones, Tablets & HMDs

Experience MRC Reality, a free app for smartphones, tablets, and HMDs, that lets you visualize and interact with full-sized robots to assess movement space and test operations before installation.

02:13 minutes

Accessories for the OVR 3-Axis Horizontal Articulated SCARA Robot

The OVR SCARA Robot is a small industrial robot that combines αSTEP AZ Series Hybrid Step-Servo motors—equipped with battery-free absolute sensors—with arm components. This video shows how accessories can facilitate quick installation of SCARA robots or additional components like end-effectors.

05:01 minutes

Grease Dispensing Equipment

This video showcases an automated grease application system using the MRC01 controller and OVR Series robotic arms. With DGII rotary actuators and EZS electric sliders, it ensures consistent results, reduces variability, and supports multi-product production with automatic dispenser changes.

01:28 minutes

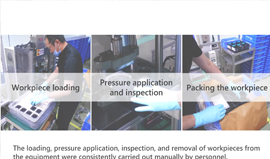

Automating the Supply and Discharge of Workpieces

This video showcases an automated system with precise pressurization, inspection, robotic packing, and automatic bucket replacement. The MRC01 controller enables easy programming, while OVR robots feature replaceable parts to reduce downtime and maintenance.

02:52 minutes

Introducing the OVR Small Robot: 3-Axis Horizontal Articulated SCARA Robot

The OVR SCARA Robot is a small industrial robot that combines αSTEP AZ Series Hybrid Step-Servo motors—equipped with battery-free absolute sensors—with arm components. It's ideal for automating in areas where conventional industrial robots are too large or too costly overall.

03:56 minutes

UR+ Certified Product: DGII Series

The DGII Series hollow rotary actuators have been added to the UR+ ecosystem. It's easy to configure with URCap. The rotary table mechanism can be moved in conjunction with the robot.

01:53 minutes

Fanuc Plugin Peripherals: DGII Series

Fanuc's CRX Series collaborative robot is now compatible with the DGII Series hollow rotary actuator, which can rotate in sync with the robot. With the required Tablet TP and plugin software, the actuator can be easily controlled through the pendant.

02:01 minutes

Small Robots OVR 3-Axis SCARA OVR3041K3-H

MRC01 links to the host controller using EtherNet/IP™ for direct control. You can easily introduce OVR Series robots or in-house robots without making significant changes to the control system for existing equipment.

01:14 minutes

OVR Small Robot Application Example: Parts Transport for Cleaning Station

The OVR articulated robot, shown in the bottom-right, uses a 3-finger gripper to move the part to the cleaning station after the top-left robot picks it from the conveyor, rotates it, and places it on the table. After cleaning, the part is returned to the conveyor.

00:38 seconds

MRC Robot Controller

The MRC01 robot controller supports easy programming and control of in-house designed custom built robots with 3 simple steps: Initial Setup, Operating Programming and Operational Checking.

01:12 minutes

Introducing Small Robots OVR

The OVR Series is a compact, lightweight industrial robot easily controlled by the intuitive MRC01 controller for simple multi-axis automation. Select motors can be replaced, helping reduce maintenance costs.

03:02 minutes

Robot Applications

The connection between the MRC01 and host system is controlled directly via EtherNet/IP™. Custom-built robots can be added easily, without the need to make major changes to the control system from the existing equipment.

01:47 minutes

Build Your Own Robot Using Oriental Motor Components

Create just the right automation solutions for your needs and achieve the intended motion. Intuitive icon-based controls allow for easy operation of the robot without the need for a ladder logic.

02:16 minutes

7-Axis Articulated Robot Demo and System Configuration

A 7-axis articulated robot demonstration using only AlphaStep AZ Series motion control products.

01:59 minutes

AZ Series 7-Axis Articulated Robot Demo and System Configuration

This robotic arm demo utilizes products from our AZ Series AlphaStep Hybrid Control System family of products, including the new AZ Series Compact Driver. Our Engineering Manager Bryan demonstrates and goes over the key components that make up and drives our 7-axis articulated robot arm.

08:07 minutes

Parallel Delta Robot Using AZ Series Stepper Motors with Hybrid Control

A compact and lightweight parallel Delta robot that uses AlphaStep AZ Series line of product: 3 AZ Series with harmonic gear stepper motors and 1 EtherCAT compatible multi-axis driver.

01:05 minutes

Robot Arm Demo Set with AZ Series

Closed loop stepper motor unit AZ Series with absolute sensor in action within a robot arm application.

01:23 minutes

Fans

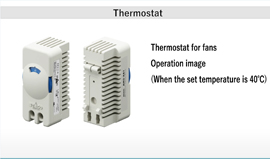

Thermostat Use

Thermostats automatically control fan ON/OFF based on temperature fluctuations, improving equipment performance in terms of energy savings and noise reduction.

00:26 seconds

Cooling Fan Types and Applications

The different types of thermal management and their applications.

01:23 minutes

Device Ventilation and Cooling with Axial Fans

Axial fans use a propeller to generate airflow along the axis of rotation, making them ideal for applications requiring ventilation and cooling.

02:40 minutes

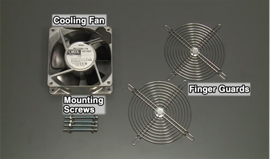

Axial Fan Kit Installation

Various accessories will help you improve the safety and utility of fans. We recommend our fan kits, which combine the fan and necessary accessories in a convenient package.

01:34 minutes

Enclosure Fan Installation

Enclosure fans provide exhaust or suction airflow, offering easy installation, superior ventilation, and protection against dust, moisture, and foreign objects.

01:34 minutes

Software

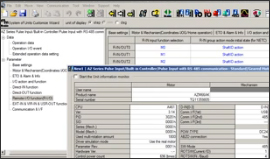

Introduction to the MEXE02 Product Support Software

The MEXE02 Product Support Software offers complete control over Oriental Motor motion control products. This video highlights its versatility.

03:52 minutes

MEXE02 Support Software: AZ Series Positioning Operation by Sensor Activation

By using figures to depict movements, we will explain how to configure the data for a positioning operation activated by a sensor.

05:49 minutes

MEXE02 Support Software: DGII Series Wrap Function Settings

This video demonstrates how we use the MEXE02 support software to configure the wrap function settings on the DGII Series rotary actuator driver.

04:10 minutes

MEXE02 Support Software: AZ Series Standard and Geared Type Wrap Function Settings

In this video, we will explain how to configure the data for a wrap function parameters on an AZ Series driver.

04:10 minutes

MEXE02 Support Software: AZ Series Wrap Positioning Operation for Indexing

In this video, we explain an operation that utilizes the wrap function in an AZ Series driver.

01:45 minutes

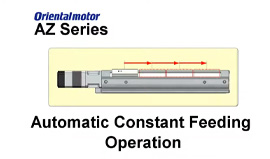

MEXE02 Support Software: AZ Series Automatic Constant Feeding Operation

An automatic constant feeding operation is a motion that repeats the same position distance. By using figures to depict movements, we will explain how to configure the data for an automatic constant feeding operation.

02:41 minutes

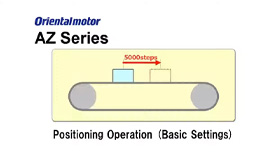

MEXE02 Support Software: AZ Series Positioning Operation (Basic Settings)

Learn how to use the MEXE02 support software to configure the stored data in an AZ Series driver.

03:06 minutes

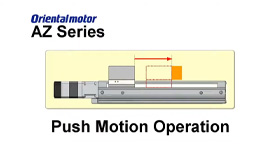

MEXE02 Support Software: AZ Series Push Motion Operation

With a push motion operation, the motor can continuously apply a set force against an object as shown. We will explain how to configure the data for a push motion operation.

02:35 minutes

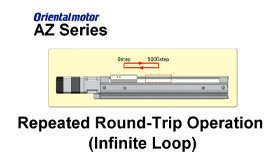

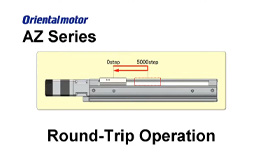

MEXE02 Support Software: AZ Series Round-Trip Operation (Infinite Loop)

We will explain how to use the MEXE02 support software to configure the data for a repeated round-trip operation with infinite cycles.

03:40 minutes

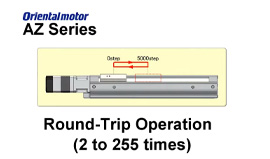

MEXE02 Support Software: AZ Series Round-Trip Operation (2 to 255 times)

This video will demonstrate how to configure the data for a repeated round-trip operation, between 2 to 255 cycles.

04:46 minutes

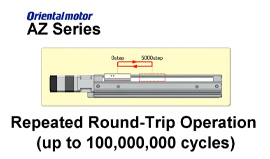

MEXE02 Support Software: AZ Series Repeated Round-Trip Operation (~100,000,000 cycles)

This video will demonstrate how to configure the data for a repeated round-trip operation up to 100,000,000 cycles.

04:37 minutes

MEXE02 Support Software: AZ Series Round-trip Operation

This video will explain how to configure data for a round-trip (return trip) operation using an AZ Series driver.

03:15 minutes

MEXE02 Support Software: AZ Series Variable Speed Operation with Linked Position Data

By using figures to depict movements, we will explain how to configure the data for a variable speed operation with linked data.

02:53 minutes

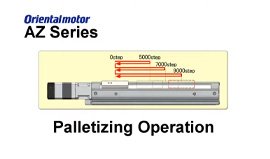

MEXE02 Support Software: AZ Series Palletizing Operation

A palletizing operation is a motion that utilizes repeated round-trip operations. The amount of travel increases with every strip. In this video, we will explain how to configure the data for a Palletizing Operation.

05:43 minutes

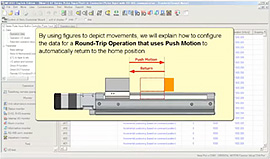

MEXE02 Support Software: AZ Series Round-Trip Operation with Push Motion

By using figures to depict movements, we will explain how to configure the data for a round-trip operation that uses push motion to automatically return to the home position.

06:31 minutes

For MEXE02 software instructional videos for RKII Series or AR Series, please visit our YouTube channel.

PLC Tutorials

Allen-Bradley

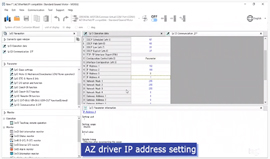

How-to: Use AZ Series EDS File on Allen-Bradley PLC with Studio 5000

This is an introduction video to installing and using an EDS (Electronic Data Sheet) file for an αSTEP AZ Series network type driver with EtherNet/IP communication in conjunction with Rockwell Automation's Studio 5000 Design software.

02:21 minutes

How-to: Add AZ Series EtherNet/IP Driver an Allen-Bradley PLC Using Logix Designer

This video demonstrates how to add an EtherNet/IP-enabled αSTEP AZ Series network type driver module to the Logix Designer software.

03:55 minutes

How-to: Install AOI into an EtherNet/IP-enabled AZ Series Driver Using Logix Designer

Learn how to install Add-on Instructions (AOI) to an EtherNet/IP-enabled αSTEP AZ Series network type driver using the Logix Designer software.

02:49 minutes

How-to: Jog AZ Series EtherNet/IP Motor on Allen-Bradley PLC in Logix Designer

Learn how to jog an EtherNet/IP-enabled AZ Series motor using the Logix Designer software with AZ controller tag mapping.

3:05 minutes

How-to: Use ZHOME AOI with AZ Series on Allen-Bradley PLC in Logix Designer

This video will show how to use the Zhome AOI. This can be done after adding the AZ modules. If the AZ module has not been installed, please see the "How-to: Add AZ Series EtherNet/IP Driver an Allen-Bradley PLC Using Logix Designer" video.

03:21 minutes

How-to: Use the DDO AOI in Logix Designer on an Allen-Bradley PLC

This video will show how to use the DDO (Direct Data Operation) AOI. This can be done after adding the AZ modules. If the AZ module has not been installed, please see the "How-to: Add AZ Series EtherNet/IP Driver an Allen-Bradley PLC Using Logix Designer" video.

04:12 minutes

How-to: Use the Monitor AOI in Logix Designer on an Allen-Bradley PLC

This video will show how to use the monitor AOI. This can be done after adding the AZ modules. If the AZ module has not been installed, please see the "How-to: Add AZ Series EtherNet/IP Driver an Allen-Bradley PLC Using Logix Designer" video.

02:42 minutes

How-to: Use the 'Write' AOI in Logix Designer on an Allen-Bradley PLC

Learn how to use the ‘Write’ AOI in Rockwell Logix Designer on an Allen-Bradley PLC. This quick tutorial guides you through configuring the Write instruction for effective data updates with an αSTEP AZ Series network type driver.

03:57 minutes

How-to: Use the 'Read' AOI in Logix Designer on an Allen-Bradley PLC

Learn how to use the ‘Read’ AOI in Rockwell Logix Designer on an Allen-Bradley PLC. This quick tutorial shows step-by-step setup to help you efficiently access PLC data with an αSTEP AZ Series network type driver.

04:15 minutes

How-to: Use the 'MOVE' AOI in Logix Designer on an Allen-Bradley PLC

03:35 minutes

Keyence

How-to: Learn How to Set Up an AZ Driver on a Keyence KV-8000/KV-7500 PLC

Learn how to set up an αSTEP AZ Series network type driver on a Keyence KV-8000/KV-7500 PLC using the KV Studio software.

03:55 minutes

How-to: Learn How to Operate an AZ Driver on a Keyence KV-8000/KV-7500 PLC

Learn how to operate an αSTEP AZ Series network type driver on a Keyence KV-8000/KV-7500 PLC using the KV Studio software.

05:03 minutes